INTRALOGISTICS IN AUTOMATION - THE KEY TO BOOSTING PRODUCTION EFFICIENCY

In the era of digital transformation and Industry 4.0, intralogistics plays a pivotal role in optimizing internal processes within factories and smart warehouses. With the integration of automation solutions, intralogistics not only accelerates handling speed but also minimizes operational costs and human error.

What is Intralogistics?

Intralogistics refers to all activities related to storing, transporting, and handling materials within an organization - such as factories, warehouses, or distribution centers. When combined with automation technologies, intralogistics becomes a smart, closed-loop, and highly efficient system.

Why Is Automated Intralogistics Important?

✅ Increases the speed of material and order handling

✅ Reduces dependency on manual labor

✅ Ensures accuracy and safety in operations

✅ Enables real-time data monitoring and tracking

✅ Enhances overall production system efficiency

Common Automated Intralogistics Solutions

- Automated Guided Vehicles (AGVs) & Autonomous Mobile Robots (AMRs)

- Automated Storage and Retrieval Systems (AS/RS)

- Automated sorting and packaging systems

- Warehouse Management Systems (WMS) with IoT and AI integration

Practical Applications of Intralogistics Automation

Automated intralogistics solutions are being widely adopted across industries such as:

- Electronics Manufacturing: AGVs transport semi-finished goods between production lines

- Food & Beverage: Robotic palletizing, automated cold storage systems

- E-commerce & Logistics: High-speed order sorting, 24/7 autonomous warehouses

- Pharmaceuticals: Traceability control, intelligent temperature-sensitive storage

These systems operate with high precision and minimal human intervention, helping businesses reduce costs and scale operations more efficiently.

Core Technologies Behind Automated Intralogistics

Modern intralogistics implementation is not just about “buying equipment.” It requires the seamless integration of multiple advanced technologies:

- AI (Artificial Intelligence): Predicts storage demand, optimizes robot routing

- IoT (Internet of Things): Monitors equipment and material status in real time

- Big Data & Analytics: Analyzes material flows and operational behavior for continuous improvement

- SCADA / MES / WMS / ERP: Synchronizes data from the shop floor to the management level

This integration empowers enterprises to gain full control from production to final delivery.

Why Businesses Should Invest Early in Intralogistics

Automated intralogistics is no longer a trend - it’s a critical competitive advantage:

- Shortens production and delivery lead times

- Reduces operating costs and optimizes workforce

- Enhances workplace safety and product quality

- Scales flexibly with business growth

With a long equipment lifecycle (5–10 years), high efficiency, and fast ROI, investing in intralogistics delivers long-term value for businesses.

AFM - Your Trusted Intralogistics Automation Partner

With over 10 years of experience in automation and machinery, AFM Vietnam Automation JSC provides smart intralogistics solutions tailored to your production specifics and business scale. Our services include:

- Automated internal transport systems

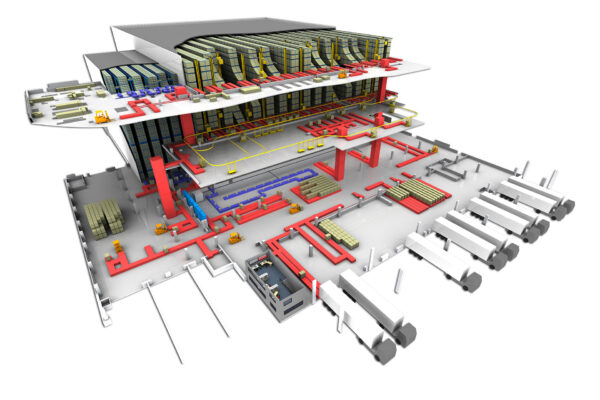

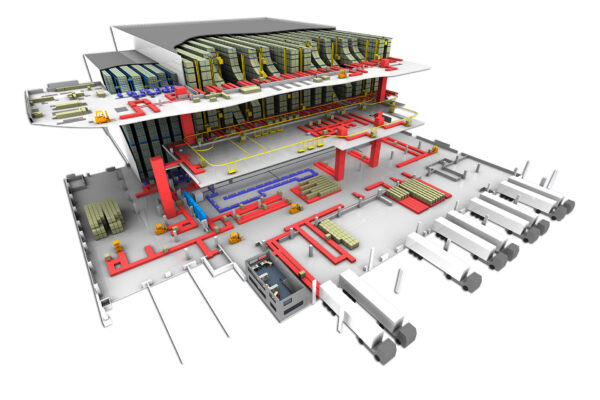

- Space optimization and material flow design

- Integrated control, monitoring, and software systems

Intralogistics Consulting for Your Factory

At AFM, we don’t just sell equipment - we partner with you throughout the process: from site assessment and material flow analysis to 3D layout design, system implementation, and operator training.

We understand that every industry and every business has unique workflows. That’s why our intralogistics solutions are always custom-designed to solve specific operational challenges for maximum efficiency.

Contact AFM today and let us meet your automation needs!