CARTON CONVEYOR SYSTEM AND PALLETIZING ROBOT

On March 4, 2024, TH Milk Joint Stock Company and AFM Vietnam Automation JSC officially signed a contract for the supply and installation of the Carton Conveyor System, Product Carton Palletizing Robot, and Stretch Wrapping System for five production lines from Mega 1.5 to the warehouse.

AFM Vietnam Automation JSC is honored and proud to partner with the TH Milk brand and contribute in our own small way to the mission that the TH Group is pursuing - bringing high-quality, healthy products to Vietnamese consumers.

This is a key project at the TH Fresh Milk Factory, designed to transfer finished milk cartons from five production lines to the warehouse in a fast and safe manner. Given the strict technical requirements set by TH, AFM delivered a comprehensive solution using over 400 meters of elevated Flexlink conveyor system, and two ABB robots for palletizing and wrapping. This ensures that fresh milk cartons are always transported and preserved in optimal condition, ready to reach every household.

Project overview

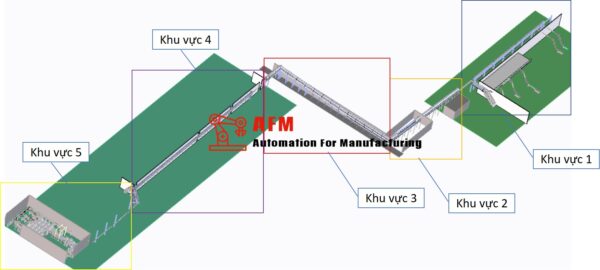

The entire project is divided into five main zones:

Zone 1: Carton Collection and Elevation

This zone receives fresh milk cartons from the outfeed conveyor of the carton packing machines. AFM engineers designed a carton pusher module to move the cartons horizontally to the elevated level.

The elevated carton conveyor uses a double-track X85X conveyor to prevent denting, with cartons guided by gravity rollers on both sides for stable transfer.

From five separate production lines, the cartons are merged onto a central conveyor using a mechanically designed lane-merging unit, ensuring stability and smooth integration.

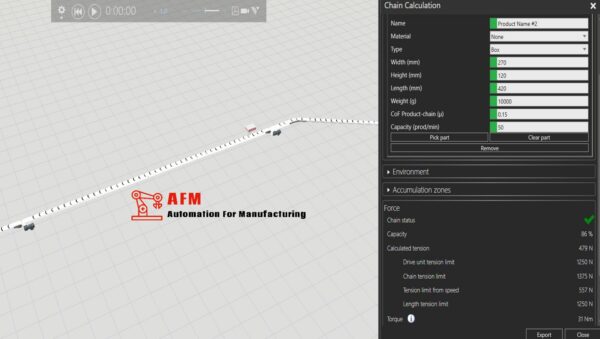

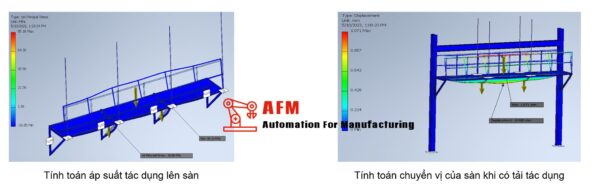

All conveyor systems in this project were carefully calculated and simulated using dedicated engineering software.

Zones 2, 3, and 4: Carton Transfer to Palletizing Area

These zones are responsible for transporting cartons from the production area to the palletizing system in the warehouse.

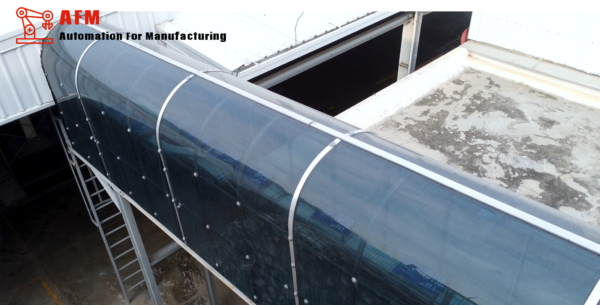

To support easy maintenance, elevated maintenance platforms were designed using I100–I150 columns and threaded suspension rods from the ceiling for structural stability during operation. All structures were engineered to meet safety standards, including 1,000 mm-high guardrails that comply with Vietnamese National Standards (TCVN).

For outdoor sections, to protect the cartons from sun and rain exposure, 5 mm thick polycarbonate roofing was installed.

Despite complex and varied terrain across these zones, AFM engineers successfully designed flexible and site-adapted solutions to meet all conditions.

Zone 5: Sorting, Palletizing & Wrapping

This is the most critical zone of the project. All cartons are transferred here for sorting by production line, then palletized, stretch-wrapped, and labeled before storage.

AFM engineers installed two vision systems to read the OCR codes on each carton. Once scanned, the PLC controller sends a signal to the Intralox sorting conveyor, directing each carton to the correct line among the five defined in Zone 1. This was one of the major technical challenges of the project, as the system needed to handle 2,550 cartons/hour (approx. 1.3 cartons/sec). To meet this demand, AFM implemented a state-of-the-art carton sorting technology, being applied for the first time in Vietnam.

Once sorted, two ABB industrial robots handle the palletizing process, stacking cartons layer-by-layer based on a pre-programmed layout.

The palletizing area is fully automated, including pallet dispensing, wrapping, and labeling. Operators only need to load empty pallets into the pallet dispenser and collect the finished pallet from the roller conveyor. All other stages are carried out automatically by the integrated system.

This project involved highly demanding technical specifications, requiring the system integrator to deliver the most optimized and reliable solutions to meet the client’s strict criteria.

AFM Vietnam Automation JSC made significant efforts and boldly applied the most advanced engineering technologies to successfully complete this project.