AUTOMATED WELDING ROBOTS - THE FUTURE OF INDUSTRIAL MANUFACTURING

As today’s industrial economy continues to grow, the application of robotics in manufacturing has become one of the most effective automation solutions for reducing operational costs. Industrial robots such as palletizing robots and feed bag stacking robots in livestock production have already delivered significant benefits in production lines. Among them, automated welding robots are a leading application, widely used in sectors such as motorcycle and automobile frame manufacturing, water heater tank production, and more.

What is an automated welding robot?

An automated welding robot is an industrial robot programmed to replace manual welders in production environments. These robots can perform either fully or semi-automated welding tasks. In processes where identical welds are performed repeatedly, welding robots are programmed with a standard procedure, ensuring consistent and precise weld quality.

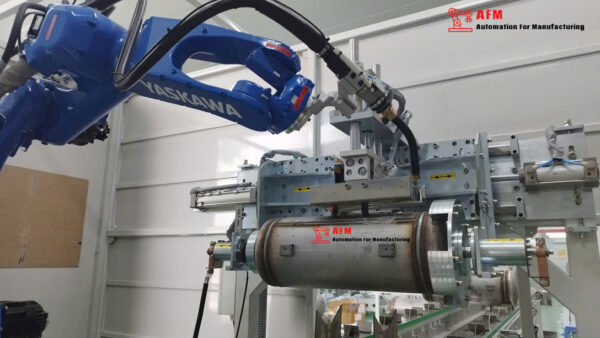

With rapid development in recent years, some of the most trusted and widely used welding robot brands include ABB, Yaskawa, Kuka, and Panasonic, among others.

Key components of an automated welding robot

1. Robotic arm

The robotic arm is designed with multiple joints, mimicking the flexibility of a human arm. This allows the robot to move freely and reach complex angles, including hard-to-access weld spots. The welding torch angle and arm movement can be adjusted to accommodate various welding positions.

2. Welding power source

This supplies the electrical current needed for the welding process. There are two main types: electronic and mechanical power sources. Automated arc welding machines must be connected to a power source to achieve optimal performance.

3. Welding machine

This component directly performs the welding operation. Various welding methods are applicable to robotic systems, such as TIG, MIG/MAG, shielded metal arc welding (SMAW), or plasma welding.

4. Control unit & sensor system

The robot operates using a programmable controller (PLC) or computer. The controller plays a critical role in directing the robot, ensuring the welding torch reaches the exact weld point.

Sensors help the robot identify the position of the workpiece and adjust accordingly, reducing errors. These include optical sensors, force sensors, and position sensors.

5. Welding fixture (Jig)

The fixture securely holds the workpiece in place during welding. Fixtures can be installed on conveyors, allowing finished products to be moved automatically to the next stage of production.

6. Gas conversion system & torch cleaning unit

The gas conversion system transfers shielding gas from storage tanks to the welding torch. The torch cleaning unit removes debris and spatter from the welding tip after use. Regular cleaning helps extend the torch’s lifespan and reduce replacement or repair costs.

Advantages of welding robots vs. manual welding

Compared to manual welding, robotic welding offers numerous advantages:

- Continuous operation & flexibility: Robots work around the clock and navigate freely, increasing speed and accuracy.

- High precision: Pre-programmed operations ensure consistent, aesthetic weld seams across products.

- Improved safety: Welding is carried out without human involvement, minimizing exposure to dangerous environments.

- Cost efficiency: Reduces labor costs and minimizes material waste due to precise welding with fewer errors.

Applications across industries

Thanks to these advantages, robotic welding is widely used in industries such as:

- Home appliance manufacturing: water heaters, washing machines, microwaves

- Machinery and equipment production

- Automotive and motorcycle frame production, etc.

Welding robots have become an integral part of modern manufacturing. By automating the welding process, minimizing errors, and increasing efficiency, robotic welding not only optimizes production workflows but also ensures superior product quality. Adopting robotic welding technology helps businesses save time and costs, while opening new opportunities to improve processes and develop innovative products.

Contact AFM today so we can fulfill your automation needs!