AUTOMATED ASSEMBLY MACHINE - CAM DECO

The automated assembly machine for Cam Deco was designed, manufactured, and programmed by the AFM engineering team for the Samsung Galaxy A series smartphone line. This machine is a comprehensive automation system that consists of four main assembly stations.

Its primary functions include tape application and module assembly for the Cam Deco mold.

The system is composed of five key modules:

1. Jig conveyor

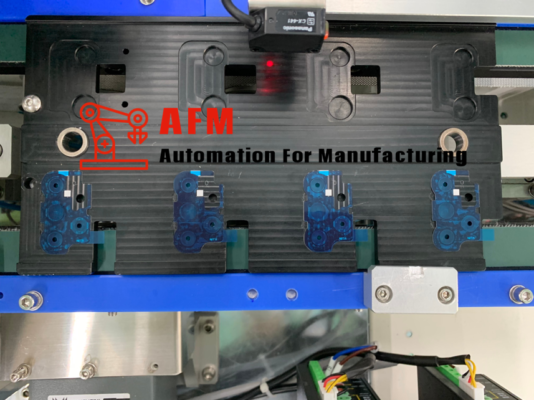

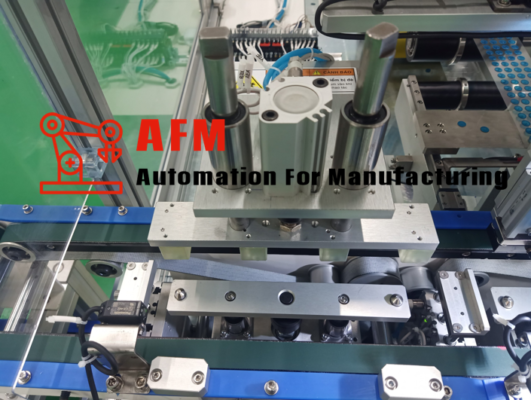

The jig conveyor uses a timing belt to transport jigs to each working station of the machine. At these stations, jig positioning modules lift the jig slightly above the conveyor and secure it precisely in place for processing.

2. Attaching tape to Cam Deco mold & pressing module

At this station, tape is supplied in reels, each containing a vertical row of tape pieces.

We utilize Cognex machine vision technology to detect the exact location of each tape on the reel. Once identified, the vision system sends a signal to a robot equipped with four vacuum suction heads, which picks up and places four tape pieces onto the jig.

After placement, the jig moves to a pressing station to secure the tape firmly in position.

3. Removing cover tape & attaching Cam Deco mold module

After tape application, the jig moves to the cover tape removal station, and then to the assembly station.

An operator loads a stack of 30 trays, each containing 24 Cam Deco Mold Modules, into the loading area.

A 3-axis XYZ robot equipped with a vacuum head picks up four Cam Deco Mold modules, places them onto an intermediate alignment station, and then places them precisely onto the taped areas on the jig.

4. 180° Reversing & attaching tape for Cam Window Macro 2

At the reversing station, the jig is rotated 180° to allow for tape application on the Cam Window Macro 2 component.

Tape is also supplied in reel format, and Cognex machine vision is used to detect the position of the tape pieces. Once detected, the robot uses its four suction heads to pick and place the tape onto the product.

5. Attaching Tape for Cam Window UW/Main 3 & Pressing Module

This module is equipped with two machine vision systems and two corresponding robots to apply different tapes:

At the Main Camera Tape Station (green tape), machine vision detects the tape position on the reel and sends signals to the robot, which then picks and places the tape onto the product.

At the UW Camera Tape Station (pink tape), machine vision performs the same function. The UW camera requires tape application at two different locations, and the process is replicated accordingly at the second station.

The CAM DECO LINE automated assembly machine is an exceptional automation solution for smartphone component assembly in general and camera module assembly in particular.

Contact AFM today to meet your automation requirements!