Due to the specific nature of the technology, textile dyeing wastewater contains high total solids (TS), suspended solids (SS), color intensity, BOD, and COD levels. Selecting an appropriate treatment method must consider various factors such as wastewater volume, characteristics, discharge standards, and whether the treatment is centralized or localized.

In principle, the following treatment methods can be applied to textile dyeing wastewater:

Mechanical Methods

Chemical Methods

Physicochemical Methods

Biological Methods

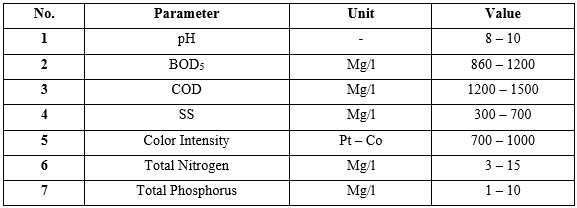

Typically, treatment technology ion is based on the color intensity and COD concentration of the wastewater. Below is a treatment technology process for textile dyeing wastewater with moderate color intensity, featuring the following parameters:

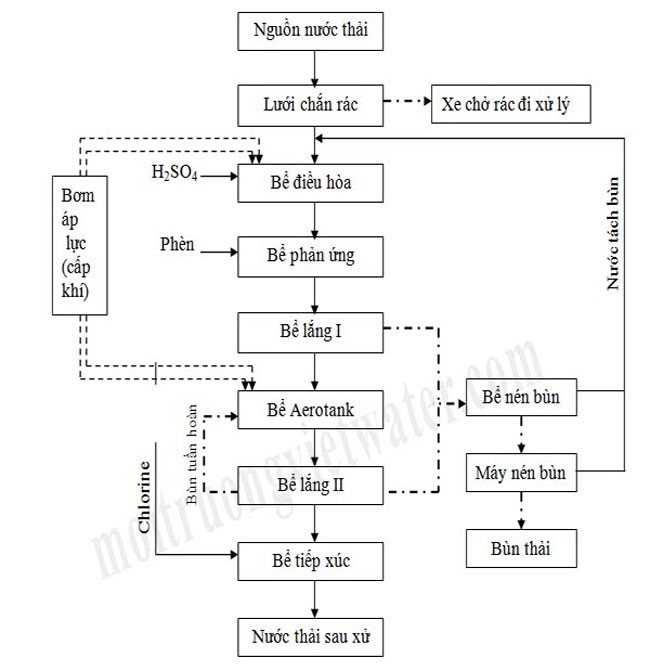

Screen Grates

Textile dyeing wastewater treatment requires the removal of large-sized materials such as dry leaves, small branches, and debris. Additionally, due to the presence of fine fibers in textile dyeing wastewater, a fine mesh screen is installed after the grates. Water flows through the screen grates at a velocity of approximately 0.6 m/s.

Equalization Tank

The purpose is to regulate the flow and stabilize concentrations for subsequent treatment units. The equalization tank in the textile dyeing wastewater treatment system is equipped with chemical dosing equipment to stabilize the pH within the range of 6.5–8.5.

Air is supplied to the tank via an aeration disk system placed at the bottom. Aeration ensures thorough mixing and maintains continuous agitation within the tank.

Reaction Tank

Used to mix chemicals with wastewater to adjust alkalinity. This creates large, heavy flocs that can easily settle in the primary sedimentation tank. Aluminum sulfate is used here due to its good solubility, low cost, and effectiveness in floc formation.

Primary Sedimentation Tank

Retains suspended solids (SS) present in the wastewater. Large flocs formed in the reaction tank settle here. The primary sedimentation tank reduces the solid load for subsequent biological treatment processes.

Aeration Tank (Aerotank)

Also known as the activated sludge tank with suspended growth. Decomposition occurs when wastewater comes into contact with sludge under continuous aeration. Microorganisms utilize organic substrates (BOD) and nutrients (N, P) as food, converting them into inert insoluble substances and generating new cells.

This transformation process continues sequentially until all substrates are consumed. After aerobic biological treatment, the wastewater is directed to the secondary sedimentation tank.

Secondary Sedimentation Tank

Sludge generated in the Aerotank and suspended solids are settled in the secondary sedimentation tank. Post-sedimentation, the treated water is conveyed to the disinfection tank, while the sludge is discharged into the sludge storage tank.

Sludge Thickening Tank

Fresh sludge from the primary sedimentation tank and activated sludge from the secondary sedimentation tank have relatively high moisture content. The sludge thickening tank reduces moisture content before the sludge is transported for further treatment.

Sludge Dewatering Machine

After passing through the sludge thickening tank, the sludge is transferred to the sludge dewatering machine. This process removes most of the water from the sludge, achieving a final sludge concentration of 15%–25% after drying.

Disinfection Tank (Chlorine Treatment)

Chlorination is used to disinfect water, eliminating microorganisms before releasing the treated water into the drainage system. This process reduces bacteria by approximately 99%.

Chlorine water is the chemical used for disinfection.

Treated wastewater complies with national standards for textile dyeing wastewater (QCVN).

Contact Viet Water Joint Stock Company today for detailed consultation!

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)