***Service Introduction

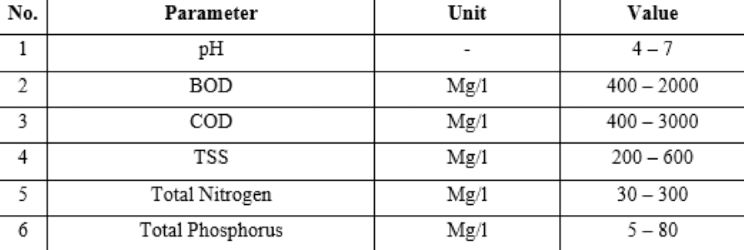

Contains high levels of nitrogen and phosphorus.

With animal-based raw materials, the wastewater typically has a high content of proteins, fats, and oils.

Elevated concentrations of TSS, BOD, COD, and bacteria.

Some food processing wastewater contains salinity, colorants, and starch.

Primarily consists of organic compounds with minimal toxic substances.

✚ Debris Screen:

Before entering the collection pit, the wastewater passes through a debris screen to remove large-sized debris (≥10mm). This prevents clogging of pipelines and pumps during the treatment process.

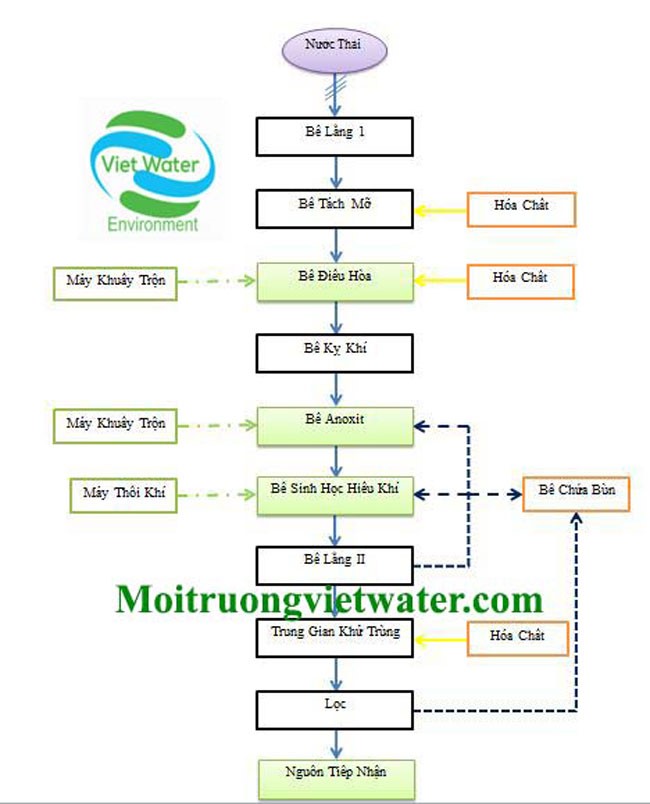

✚ Settling Tank:

The settling tank removes coarse and heavy sediments such as sand, gravel, glass shards, metal fragments, ash, and coal dust. This safeguards mechanical equipment from wear and reduces sediment load in subsequent treatment stages.

✚ Horizontal Grit Chamber:

Features straight-line water flow along the length of the chamber. It typically has a rectangular cross-section and a collection pit located at the inlet.

✚ Grease Trap:

Flotation in the food processing wastewater treatment system effectively separates insoluble, poorly settling dispersed impurities from the liquid phase.

✚ Equalization Tank:

Balances flow and concentration to create stable operating conditions for subsequent treatment stages. This reduces equipment size requirements, mitigates operational issues caused by fluctuating flows or overloads, and enhances the efficiency of downstream processes.

✚ Anaerobic Tank:

The anaerobic biological filter removes the majority of pollutants present in the wastewater (BOD, COD, SS, etc.). Initial inoculated biomass includes septic sludge, manure, and specific activated microorganisms. Dead biomass from the anaerobic filter is pumped to the sludge holding tank for disposal.

✚ Anoxic Tank:

In the anoxic tank, diverse facultative microorganisms specialized for food processing wastewater treatment metabolize and remove nitrogen from the water, facilitating energy conversion and the formation of new cells.

✚ Aerobic Tank:

Oxygen is supplied continuously by blowers to maintain required oxygen levels. Aerobic microorganisms (activated sludge) decompose remaining organic matter in the wastewater. After passing through the Aerotank, biodegradable organic pollutants are completely removed.

✚ Secondary Settling Tank:

Activated sludge and water from the Aerotank are directed to the settling tank for separation. Activated sludge settles to the bottom, and the clear water is directed through an overflow weir. Some settled sludge is recirculated back to the Aerotank and the anoxic tank, while excess sludge is periodically discharged to the sludge holding tank.

✚ Disinfection Tank:

The disinfection tank ensures thorough mixing and diffusion of disinfectant chemicals into the wastewater. This process allows adequate contact time for the chemicals to neutralize and destroy pathogenic microorganisms.

Contact Viet Water Joint Stock Company today for detailed consultation!

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)