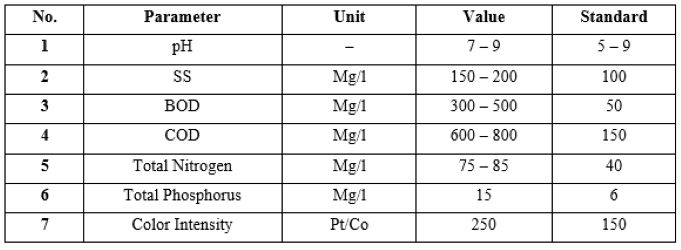

***Service Introduction

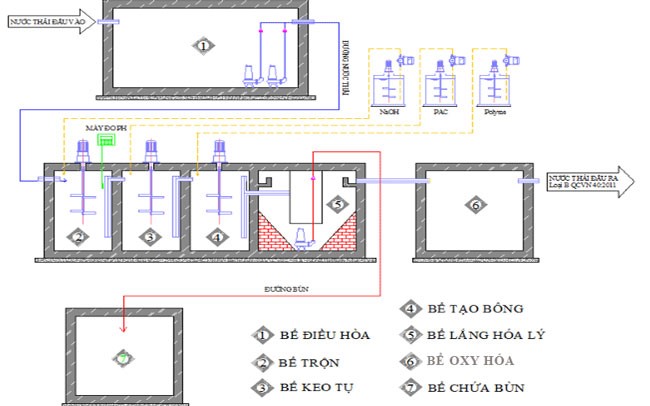

Equalization Tank

Laundry wastewater is collected in the equalization tank, which functions to regulate flow rate and pollutant concentration, ensuring consistent and thorough treatment in subsequent physico-chemical processes. From the equalization tank, wastewater is pumped by a submersible pump installed at the bottom of the tank to the mixing tank cluster.

Mixing Tank

The mixing tank serves to adjust the pH of the wastewater. Sodium hydroxide (NaOH) is dosed using an automatic pH adjustment system. This system automatically measures the pH of the wastewater, analyzes it, and signals the chemical dosing pump to adjust the pH. Simultaneously, the mixing device stirs the solution until the pH reaches the optimal value of 7.5.

Coagulation Tank

The coagulation tank aggregates pollutants into clumps by dosing PAC (poly aluminum chloride) at a 10% concentration. Wastewater is treated with a calculated PAC solution flow rate to ensure the optimal PAC concentration for handling suspended solids (SS), chemical oxygen demand (COD), and turbidity. A mixing device enhances the dispersion of coagulants in the wastewater.

Flocculation Tank

After coagulation, wastewater flows into the flocculation tank. This tank gathers smaller sludge flocs into larger ones. The flocculation process involves the addition of polymer-based flocculant aids and mechanical mixing before the wastewater is sent to the physico-chemical settling tank.

Physico-Chemical Settling Tank

In the settling tank, floc formation improves sludge sedimentation efficiency. The sludge is then directed to the sludge storage tank.

Oxidation Tank

Post physico-chemical treatment, the wastewater is further processed in the oxidation tank. Depending on the type of activity and pollutant concentration in the wastewater, the oxidation process is customized. After oxidation, the treated wastewater is discharged in compliance with environmental standards set by the Ministry of Natural Resources and Environment.

Sludge Storage Tank

The sludge storage tank collects sludge generated during the coagulation process. The sludge is pumped from the settling tank to the sludge storage tank and subsequently transferred to the sludge drying yard.

Contact Viet Water Joint Stock Company today for detailed consultation!

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)