THERMAL OIL BOILER

With a commitment to "Quality, Safety, and Competitive Pricing," Mayzer Company – headquartered in Ho Chi Minh City, with offices in Hanoi and a manufacturing plant in Long An – is ready to meet all your thermal oil heater needs nationwide.

What is a Thermal Oil Heater?

• A thermal oil heater, also known as a heat transfer oil heater, is a high-temperature but low-pressure device, making it safer, more efficient, and with lower heat loss compared to traditional boilers.

• Since it doesnt use water, it is less prone to scaling and corrosion than boilers.

Technical Specifications of Thermal Oil Heaters

• Manufacturing standards: ASME and TCVN

• Thermal output: (1,000,000-16,000,000) kcal/hour

• Operating temperature: Up to 400°C

• Operating pressure: (4-15) bar(g)

• Fuel: Indonesian coal & biomass

• Efficiency: 82%

• Heat transfer fluid: Liquid oil or vapor oil

Types of Thermal Oil Heaters

→ Vertical Thermal Oil Heaters:

• Capacity: 50,000 kcal/h to 3,000,000 kcal/h

• Temperature: 280 – 320°C

• Fuel: DO, FO, coal, wood, rice husk...

• Efficiency: 85%

• Fully automatic

→ Horizontal Thermal Oil Heaters:

• Capacity: 2,000,000 kcal/h to 15,000,000 kcal/h

• Temperature: 280 – 320°C

• Fuel: Biomass: Sawdust, wood chips, coal fines, rice husk, wood chips, etc.

• Efficiency: 85%

• Fully automatic

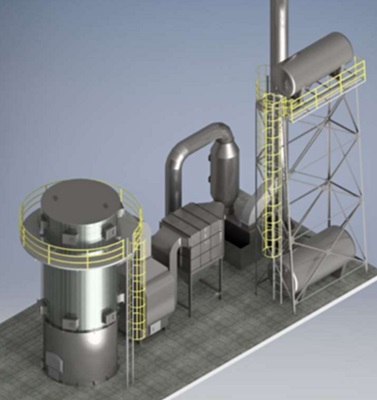

Construction of a Thermal Oil Heater

• Feeding system: Equipped with automatic or semi-automatic operation (including equipment such as loaders, hoppers, bucket elevators, conveyors, screw conveyors...) arranged for interlocked, metered, and automatic feeding of fuel to the thermal oil heater.

• Combustion chamber - furnace body: Designed for complete fuel combustion and optimal heat absorption for heat generation.

• Flue gas heat recovery unit: Used to recover heat from flue gas and increase efficiency.

• Dust collection system: Cyclone dust collector system with up to 99% dust removal efficiency. Additionally, bag filter systems or Venturi wet scrubbers can be used for dust treatment. These dust collection devices ensure that the flue gas from the thermal oil heater meets the most stringent environmental standards.

• Induced draft fan and chimney: The flue gas, after passing through the dust collection system, is drawn by the induced draft fan and discharged into the atmosphere through the chimney.

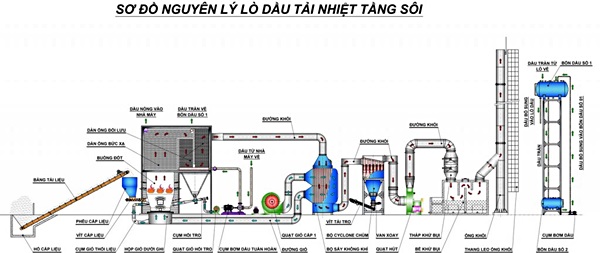

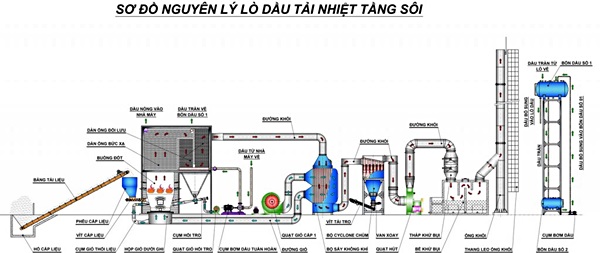

Operating Principle of a Thermal Oil Heater

• Fuel is fed into the combustion chamber and burned, with air supplied from below to provide oxygen for combustion.

• Combustion products (flue gas) and flames exchange heat (mainly by radiation) with the heat exchanger tube bundle, heating the oil circulating forcefully (driven by an oil pump) inside the tubes. After heat exchange at tube bundle 1, the flue gas returns to pass 1 (the space between tube bundle 1 and tube bundle 2) and exchanges heat with both bundles again. Then, the flue gas goes to pass 2, which is the narrow gap between the outer surface of tube bundle 2 and the furnace wall.

• After receiving heat from the flue gas, the oil heats up and exits to the heat-using equipment.

• After heat exchange, the flue gas temperature decreases and is discharged to the atmosphere by the induced draft fan. Since the flue gas exiting the furnace has a high temperature, an air heater is installed behind the furnace to recover heat from the flue gas.

• The flue gas, after passing through the air heater, enters the dust collection system, such as a cyclone and bag filter system or wet scrubber.

• The clean flue gas, after being treated, is discharged into the atmosphere through the chimney.

Why choose Mayzer for your thermal oil heater?

▼ Guaranteed to meet environmental standards and quality

▼ Regular inspection every 3 months

▼ Operator training program

▼ Lifetime maintenance support. Warranty for any manufacturing defects.

Contact Us for More Info:

◈ Hotline: +84 942090089

◈ Email: mayzervietnam@gmail.com