FLUIDIZED BED BOILER

Why are fluidized bed boilers so popular in industries such as packaging, seafood processing, animal feed, food, pharmaceuticals, and textiles? These boilers offer significant economic benefits and operational advantages.

• Quick and easy start-up: The fluidized beds high turbulence allows for rapid startup and shutdown without pressure s.

• Consistent performance: Ideal for medium to large-scale operations, fluidized bed boilers provide stable and efficient operation.

• Low maintenance costs: With a long lifespan and durable construction, these boilers require minimal maintenance.

• Reduced cleaning time: The alkaline components in the ash evaporate, preventing buildup and reducing cleaning frequency.

Dive in to find out the Fluidized Bed Boiler as follows:

What is a fluidized bed boiler?

• A fluidized bed boiler is a type of boiler where fuel is introduced into a bed of material that is fluidized by high-temperature air, causing the fuel to spontaneously ignite.

• The fluidized bed consists of non-combustible solid materials such as sand, ash, and slag, which move up and down due to the airflow created by the air blown through the nozzles. The air not only maintains the fluidized bed but also supplies oxygen for the combustion process.

• Fluidized bed boilers are capable of efficiently burning various types of solid fuels with different properties, typically with a particle size of less than 10 mm. They provide high heat output, which improves combustion efficiency and increases power generation during operation.

• Research has shown that multi-stage fluidized bed boilers can significantly reduce harmful emissions, such as NOx, by over 30% compared to pulverized coal boilers.

Characteristics of Fluidized Bed Boilers

• The characteristic of this boiler is that it burns fuel based on volume, meaning that when the fuel is fed into the combustion chamber, it burns under sufficient pressure, drawing in the burning fuel suspended in the air within the combustion chamber.

• The fluidized bed technology involves volume combustion. The burning fuel fills the combustion space, which increases heat exchange efficiency, ensuring that the fuel burns completely without wastage.

Advantages of Fluidized Bed Boilers

• The combustion chamber is smaller compared to traditional boilers, reducing heat loss to the environment, thereby increasing the boilers efficiency.

• As the fuel burns suspended in the combustion chamber, the chamber has a larger volume, which improves heat exchange.

• As a result, the boiler’s efficiency increases by 7-10%, and the exhaust gas quality meets environmental standards.

• The fuel’s combustion time is shorter, so the highest temperature in the combustion chamber only reaches 600-700°C (for biomass fuel).

• At this temperature, the fuel produces minimal ash, and the ash does not form hard clumps, allowing for automatic ash removal through a rotary valve at the bottom of the grate.

• It can burn a variety of fuels: coal dust, loose rice husks, rice husk pellets, chopped wood, wood pellets, etc.

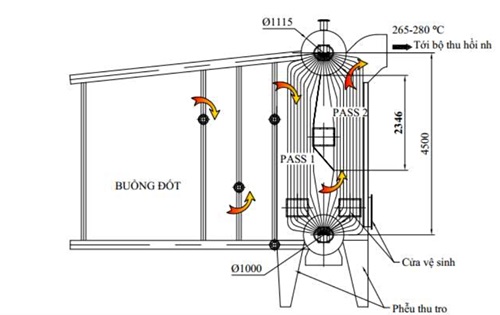

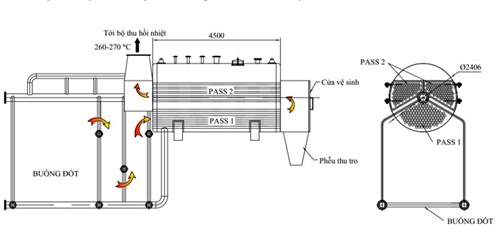

Working Principle of a Fluidized Bed Boiler:

• Fuel from the storage is fed into the boiler using conveyors, where it enters a hopper and is transported into the combustion chamber by a screw feeder. The fuel is then evenly spread across the combustion chamber surface by an air blower.

• Inside the combustion chamber, the fuel is burned in a fluidized bed (non-combustible particles like coal ash, sand, or rocks). Primary air is supplied from beneath the grate to provide oxygen for combustion, and it also helps move the fuel. The fluidized bed moves up and down, suspended in the combustion chamber, similar to the boiling of a liquid, which is why it’s called a fluidized bed.

• When the fuel burns in the combustion chamber, it produces ash, and light particles are carried by the suction force of the fan, traveling along with the flue gas.

• However, any unburned fuel particles, which are heavier, will lose their momentum when the flow turns in the recirculation chamber and fall into the recirculation hopper. These particles are then returned to the combustion chamber for continued burning until completely consumed. This process is why it’s called a circulating fluidized bed (CFB).

• The flue gas, after passing through the recirculation chamber, enters the convection tube bank, where it exchanges heat with the water circulating through the tubes.

• The exhaust gas, still at a relatively high temperature of 250–300°C, then passes through the economizer and air pre-heater to recover heat, which warms the water before it enters the boiler and pre-heats the combustion air, thus improving boiler efficiency.

• Afterward, the flue gas passes through a cyclone dust collector, where larger and finer dust particles are separated and fall into a dust hopper. However, ultra-fine dust particles that are not captured by the cyclone will follow the gas flow into a fabric filter bag, where dust accumulates on the outer surface of the bags. The clean gas then passes through and is exhausted by the fan into the chimney.

• As dust accumulates on the fabric filter bags, the resistance increases. To clean the filters, compressed air from the air compressor is used to pulse and shake the bags, causing the dust to fall into the hopper. This cleaning process is called "filter bag regeneration."

Types of Fluidized Bed Boilers:

Water Tube Fluidized Bed Boiler (2-drum boiler)

Water Tube and Fire Tube Combined Fluidized Bed Boiler (1-drum boiler)

Main Equipment in Fluidized Bed Boilers:

• Fluidized Bed Combustion Chamber: This is where the fuel is burned. The combustion chamber walls are made of firebricks and are lined with insulation and 3mm sheet metal.

• Radiation and Convection Chambers: These are responsible for steam generation. Made of header pipes and heat exchanger tubes from cast steel, these are insulated and covered with sheet metal.

• Boiler Drum: This part generates steam. The drum is made from heat-resistant A515 steel, insulated and covered with sheet metal.

• Economizer: This device recovers heat from the exhaust gas to preheat the water before it enters the boiler, improving efficiency and reducing the exhaust gas temperature.

• Air Pre-heater: This recycles heat from the exhaust gas to warm up the air before it enters the combustion chamber, enhancing fuel combustion efficiency and reducing the exhaust gas temperature.

• Multi Cyclone Dust Collector: A series of cyclones used to capture dust generated during combustion.

• Fabric Bag Dust Filter: Composed of fabric bags that filter out fine dust particles that the cyclone could not capture.

• Flue Gas Stack: The exhaust chimney, typically made from steel or stainless steel, is used to release flue gases into the environment.

Control System for Fluidized Bed Boilers:

• Water Feed Pump Control: Ensures that the water level in the boiler drum is maintained at 50-60% of the full capacity.

• Pressure Control: Uses sensors to regulate steam pressure according to requirements, ensuring system safety.

• Combustion Chamber Pressure Control: Maintains the temperature and pressure in the combustion chamber to ensure safety around the boiler.

• Excess Oxygen Control: Optimizes fuel combustion efficiency and reduces CO emissions.

• SCADA Control: Displays the boiler’s operational diagram, helping operators monitor and control the entire boiler operation.

Why Choose Our Fluidized Bed Boilers:

• Commitment to meeting inspection standards and environmental quality

• Regular inspections every 3 months

• Standardized water treatment systems for the boiler

• Free boiler cleaning agent included

• Operator training programs

• Lifetime maintenance support

Mayzer Company specializes in the installation of boiler systems and steam supply for manufacturing businesses.

For consultations or quotes, please contact our Hotline: +84 942 090 089 for assistance.