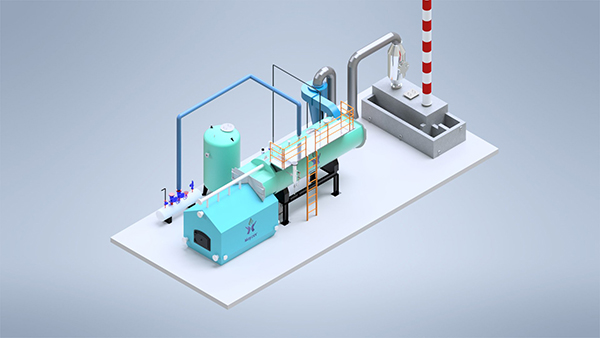

STATIONARY GRATE BOILER

Why Choose Mayzers Stationary Grate Boiler?

▼ Mayzer Company is a direct manufacturer, supplier, and installer of Industrial Boilers in Ho Chi Minh City.

▼ We offer lifetime on-site warranty and maintenance services, as well as operator training programs.

▼ Our boilers are manufactured to the highest standards.

Contact us today to experience Mayzers products and services.

What is a Stationary Grate Boiler?

A stationary grate boiler, also known as a fixed grate boiler, is an industrial boiler that uses a stationary grate for combustion. This type of boiler can handle a variety of fuels, especially those with larger sizes. Its one of the most common types of boilers due to its simplicity, long history, and suitability for small and medium-sized industrial facilities.

Types of Stationary Grate Boilers:

• Coal-fired boilers: For coal dust and lump coal.

• Biomass boilers: For wood, rice husks, wood chips, sawdust, and loose husks.

• 2-drum boilers

• 1-drum 2-pass boilers

Operating Principle of a Stationary Grate Boiler:

• Fuel is manually fed into the combustion chamber through the feed door.

• Newly fed fuel rests on the layer of burning fuel.

• Primary air is supplied from below the grate through the ash layer, preheating and igniting unburnt fuel in the ash.

• Secondary air is then supplied to continue the combustion process.

• The burning fuel transfers heat to the boiler tubes.

• After leaving the combustion chamber, the flue gas enters the tube bank for further heat transfer.

• Since the flue gas temperature is still relatively high (around 200-250°C), especially for boilers larger than 3 tons/hour, an economizer or air preheater is often installed to recover additional heat.

• The flue gas then passes through a cyclone separator.

• Finally, the flue gas goes through a wet or bag-type dust collector before being discharged through the chimney.

Classification of Stationary Grate Boilers:

Stationary grate boilers with auxiliary combustion chambers

Stationary grate boilers with tube furnaces

Benefits of Stationary Grate Boilers:

• Wide availability of fuels such as wood, coal, rice husks, wood chips, and sawdust in Vietnam, with abundant supply.

• Relatively low fuel cost compared to oil, gas, and CNG.

• Ash can be used as fertilizer, or as raw material for steel and cement production.

Advantages of Stationary Grate Boilers:

• Can burn a wide range of fuels, regardless of size or shape.

• High heat absorption and transfer due to the tall combustion chamber design.

• Long service life and stable capacity over time.

• Simple design and easy operation.

• Compact size.

• Designed and manufactured according to TCVN 7704 – 2007 standard.

• Flue gas emissions comply with QCVN 19:2009/BTNMT standard.

Disadvantages of Stationary Grate Boilers:

• As an older technology with manual operation, it requires more labor.

• Lower efficiency compared to other boiler types due to the layer-by-layer combustion on the stationary grate, typically achieving 75-80% efficiency.

• Most suitable for boilers with a capacity less than 12 tons/hour and a pressure less than 15 bar.

For inquiries or quotes, please contact our hotline.

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)