CIRCULATING FLUIDIZED BED BOILER

Mayzer Company specializes in designing, manufacturing, and producing industrial boilers in Ho Chi Minh City, including: coal-fired boilers, wood-fired boilers, oil-fired boilers, multi-fuel boilers, electric boilers, fluidized bed boilers, heat transfer oil boilers, waste fabric boilers, and boiler accessories.

Our boilers are widely used in food factories, garment factories, cooking systems, brewing systems, hot water pools, playgrounds, restaurants, hotels, massage parlors, saunas, rice noodle production systems, and other food processing facilities.

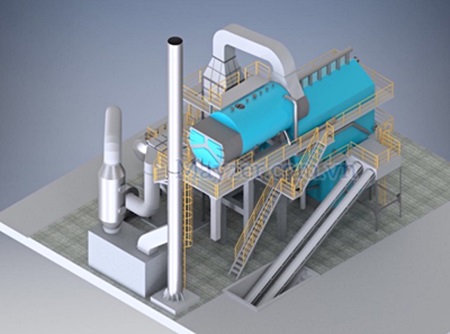

☞ Introducing one of Mayzers most reliable and high-quality products: the Circulating Fluidized Bed Boiler.

What is a Circulating Fluidized Bed Boiler?

A circulating fluidized bed boiler is a type of boiler that utilizes fluidized bed combustion technology, where burning fuel particles are continuously recirculated and completely combusted, resulting in maximum combustion efficiency and fuel savings.

Construction of a Circulating Fluidized Bed Boiler:

• Circulating fluidized bed combustion chamber

• Solid particle separation and recovery equipment

• Solid particle recirculation equipment

• Supplementary heat exchanger

Operating Principle of a Circulating Fluidized Bed Boiler:

• Fuel is fed into the furnace via a conveyor belt or screw feeder.

• Primary air, preheated by an air heater, is supplied from the bottom of the combustion chamber to create a fluidized bed and provide oxygen for combustion.

• Fuel particles are fed into the combustion chamber and evenly distributed across the chamber surface by a fuel distributor.

• Fuel particles ignite in the fluidized bed and burn most vigorously in the upper half of the combustion chamber.

• As the fuel burns, particles break down into ash. Due to their light weight, ash particles are carried out of the furnace with the flue gas.

• However, larger particles that do not burn completely undergo a particle separation process and settle back into the furnace, continuing the combustion process until they are completely consumed.

• The flue gas exiting the recirculation chamber passes through a convection bank (or radiant bank), where it exchanges heat with water through the tube walls.

• The flue gas exiting the convection bank still has a relatively high temperature of 250-300°C.

• To utilize this waste heat, the flue gas passes through an economizer and air heater to preheat feedwater and combustion air, respectively, increasing the boilers efficiency.

• The flue gas then passes through a cyclone dust collector, where larger dust particles are separated and collected in an ash hopper.

• However, the cyclone only captures larger and coarser dust particles. Very fine dust particles pass through the cyclone and are carried by the flue gas into a fabric filter (or wet scrubber).

• At this point, the flue gas is clean and is discharged into the atmosphere through a stack.

Why Choose Us?

✓ Decades of Experience: Weve been designing and manufacturing industrial boilers for many years, giving us a deep understanding of your unique needs.

✓ Versatile Fuel Options: Our circulating fluidized bed boilers can handle a wide range of fuels, including low-quality coal, biomass, and materials with high ash content.

✓ Environmentally Friendly: Our boilers meet stringent environmental standards, ensuring compliance with local regulations.

✓ Comprehensive Training: We provide comprehensive training to your operators to ensure safe and efficient operation.

✓ Lifetime Support: Benefit from our lifetime maintenance program, including warranty coverage and prompt troubleshooting.

✓ Nationwide Delivery: We deliver to all 64 provinces across Vietnam. Expect your order within 1-10 days, depending on the product and shipping method.

✓ Convenient Delivery Options: Choose from our convenient delivery options: doorstep delivery or courier service.

Mayzer specializes in installing boiler systems and providing steam solutions for industrial businesses.

Need a quote or advice? Call our hotline for immediate assistance.

.jpg)