CNC TURNING SERVICES

At EME Vietnam Technology Co., Ltd., precision mechanical services are at the core of our operations. With over 12 years of experience, we specialize in delivering high-precision machining solutions, ensuring accuracy up to 0.001mm. Our advanced CNC turning capabilities allow us to meet the most demanding client specifications, providing high-quality products that set industry standards.

What is CNC Turning?

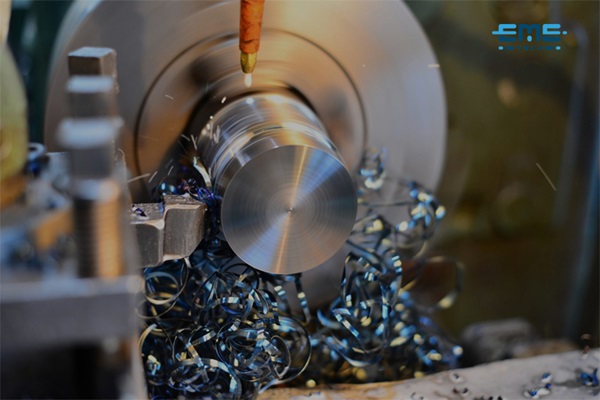

CNC turning is a modern machining process that uses CNC (Computer Numerical Control) lathes to cut and shape metal blanks into the desired form. This process involves the precise coordination of movements between the cutting tool and the workpiece. The workpiece primarily rotates in a circular motion, allowing the cutting tool to remove material and shape the product, while the tool itself moves in linear or horizontal directions. These movements are all automatically controlled by a computer, making the process efficient and highly accurate.

CNC turning offers several methods such as round turning, cone turning, groove turning, face turning, and chamfering, all depending on the type of product required. The tools used in CNC turning include shoulder cutters, hole turning tools, shaping tools, and end cutting tools.

CNC Turning at EME: Tailored to Your Needs

At EME-Tech, our CNC turning services are designed to accommodate a wide range of industries. Whether you require custom parts or mass production, we have the capability to deliver:

➢ External Cylindrical Turning

One of the most widely used CNC turning methods is external cylindrical turning. This method is ideal for shaping cylindrical surfaces, including long or wide cylinders. It requires the appropriate turning tools to create the desired outer surface of the product.

➢ Hole Turning

Hole turning is another common CNC turning technique, similar to external turning but focused on creating holes of varying sizes. This method often requires specialized tools such as boring machines or high-end hole lathes to achieve the desired precision and finish.

➢ Face Turning

Face turning involves machining the surface of a workpiece, typically to remove excess material from the head and produce a smoother surface. Various tools such as straight-head, curved-head, and shoulder knives are used to achieve the desired outcome.

➢ Cutting Off Turning

Cutting off turning resembles external turning but is distinguished by its use of less durable tools. This method requires careful tool ion to ensure product quality and prevent tool wear.

➢ Threading

Threading is a simpler method of CNC turning that is commonly used in factories. It involves the use of moderate lathes to create threads in a product. While effective, threading can be less efficient, particularly when producing small threads or working with weak tool shafts.

Why Choose EME-Tech for CNC Turning?

EME Vietnam Technology Co., Ltd. brings several key advantages to your CNC turning projects:

✓ Unmatched Precision: With our state-of-the-art CNC lathes, we achieve precision up to 0.001mm, ensuring that your parts meet the most stringent quality standards.

✓ Custom Solutions: We are capable of producing parts based on your exact designs and specifications, whether for one-off prototypes or large production runs.

✓ Efficient Production: Our advanced equipment allows us to complete projects quickly without sacrificing quality, helping you reduce lead times and stay competitive.

✓ High-Volume Capacity: With our modern facilities and experienced team, we can handle large production runs while maintaining consistent quality across all parts.

✓ Cost-Effective Results: By minimizing material waste and optimizing production processes, we offer cost-effective solutions that help reduce overall production costs.

At EME-Tech, CNC turning is more than just a machining process – It is a key component of our commitment to delivering high-precision, high-quality products. Whether you need complex components or high-volume production, our team is dedicated to providing solutions that exceed your expectations.

Let us help you bring your designs to life with precision, efficiency, and excellence. Contact EME-Tech today to learn more about how our CNC turning services can benefit your business.