JIGS AND FIXTURES PROCESSING

EME Vietnam Technology Co., Ltd. is a recognized leader in providing precision mechanical services, with 12 years of experience in the industry. With a processing accuracy of up to 0.001mm, EME-Tech has built a strong reputation as a trusted partner for major companies. The company continues to invest in cutting-edge technology with the goal of becoming Vietnam’s leading mechanical and automation hub.

What is Jigs & Fixtures?

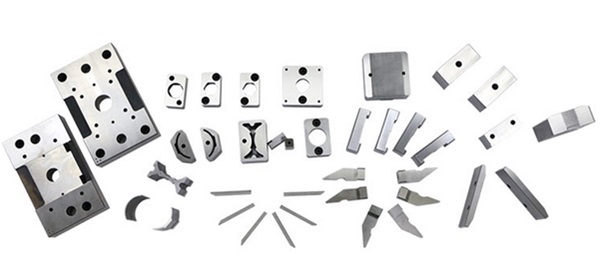

Jigs are essential tools in mechanical processing, playing a critical role in the manufacturing, testing, and assembling of electronic and mechanical products. Their main function is to position the workpiece in relation to the cutting tool and secure it firmly during machining, preventing movement or vibration caused by external forces. This ensures accurate and efficient cutting.

In addition to positioning, jigs help guide the cutting tool and can even create additional movements necessary for machining complex surfaces. When properly designed and processed, jigs significantly enhance the mechanization and automation of precision manufacturing processes, streamlining the assembly of parts and improving overall efficiency.

The Jig & Fixture Design Process

❖ Overall Research: Gaining a deep understanding of the project’s requirements.

❖ Positioning Factors: Determining how the workpiece will be positioned relative to the tool.

❖ Machine Type and Capacity: Considering the type and power of the machinery to be used.

❖ Assembly and Disassembly: Designing for ease of handling the workpiece.

❖ Power Devices: Incorporating necessary support devices like electricity, compressed air, or vacuum systems.

❖ Safety Measures: Ensuring safety with proper clearance between the jig and its parts.

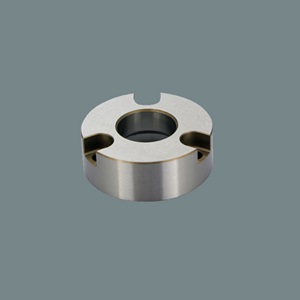

Materials Used for Jigs and Fixtures

The choice of material for a jig or fixture depends on its application and the specific demands of the machining process. Common materials include:

♦ Steel: Durable and widely used, including stainless steel and lightweight variants.

♦ Cast Iron: Known for its rigidity and stability.

♦ Aluminum: Particularly useful for lightweight applications.

♦ Plastics: Materials like Derlin, Nylon, and PC are often used for specialized applications.

♦ Copper: Suitable for specific needs due to its excellent conductivity and malleability.

Key Advantages of Jig Design and Processing

► Enhanced Product Quality: Jigs ensure consistent quality from processing to assembly and inspection. Their durability and versatility allow for use on various materials, leading to cost savings over time.

► Improved Efficiency in Mass Production: Jigs contribute to automated, high-volume production processes. Modern machinery, equipped with jigs, can handle large quantities with precision, making it an ideal choice for industries requiring mass production.

► Precision and Accuracy: When jigs are designed and processed to standard specifications, they ensure precise product parameters, reducing errors during machining.

► Customizability: Jigs can be adapted to meet specific customer requirements. Skilled technicians ensure designs are optimized, minimizing errors in production.

► Wide Range of Applications: Jigs are versatile and can be used across multiple industries, including automotive manufacturing, pump assembly, and machine part inspection. They are also crucial in processes such as drilling, boring, and tapping.

Modern Machinery at EME-Tech

EME-Tech operates with an advanced machinery and equipment system, sourcing tools from leading manufacturers in Germany, Japan, and Korea. The company’s equipment includes:

■ 3, 4, and 5-Axis CNC Milling Machines: Ensuring precise and complex machining operations.

■ CNC Lathes: Used for creating precise cylindrical parts.

■ CNC Wire Cutting Machines: Ideal for fine cutting work.

■ CNC Bending Machines: Ensuring precision in shaping metal parts.

■ 3D Object Scanners and 3D CMM Measuring Machines: Critical for ensuring that all components meet strict quality standards.

EME Vietnam Technology Co., Ltd. continues to focus on innovation and precision, aiming to deliver high-quality mechanical solutions to meet the diverse needs of its clients.