MACHINE PARTS PROCESSING

EME Vietnam Technology Co., Ltd. is proud to be one of the top providers of precision mechanical services in Vietnam. With over 12 years of experience, the company has built a reputation for machining accuracy down to 0.001mm. EME-Tech aims to become the leading mechanical and automation center in the country and has continuously invested in advanced technologies to maintain trust with large companies both domestically and internationally.

Why Choose EME for Machining Machine Parts?

Precision is at the heart of everything done at EME-Tech. Here are some of the key advantages of working with our services:

✓ Absolute Accuracy: Precision is guaranteed with every part, down to the smallest detail.

✓ High Durability: The materials used and the methods applied ensure the longevity of the machine parts.

✓ Aesthetic Excellence: Beyond functionality, our machining enhances the appearance of the parts.

✓ Versatile Applications: Whether you need parts for automotive, industrial, or specialized machinery, our services can adapt to your needs.

✓ Efficiency and Cost Savings: The careful application of machining techniques helps reduce time and costs for our clients.

Types of Machining Offered

EME-Tech offers a variety of machining services tailored to meet the specific requirements of each project:

❶ Rough Machining:

This process focuses on removing large amounts of material from the workpiece. It shapes the product to the required geometry while maintaining strong material integrity. Rough machining is perfect when the product does not require high levels of smoothness or precision.

❷ Finishing Machining:

After the rough machining stage, the workpiece undergoes finishing. This involves removing a thin layer of excess material to ensure smoothness and meet technical standards. The cutting tool used in this process is carefully protected to deliver high-quality results.

❸ Smooth Machining:

For products that demand the highest level of precision and a super-smooth finish, smooth machining is applied. Though simple, this step dramatically enhances the overall value of the part, ensuring a perfect surface.

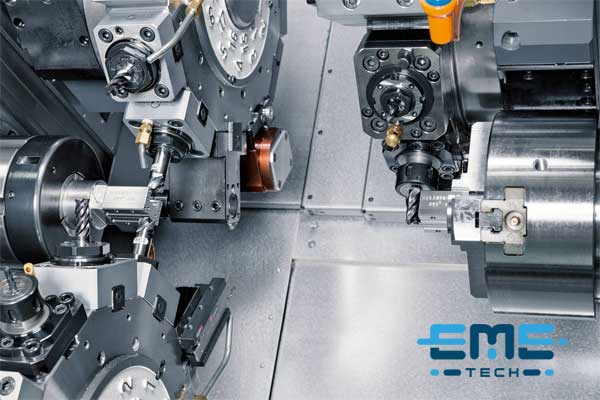

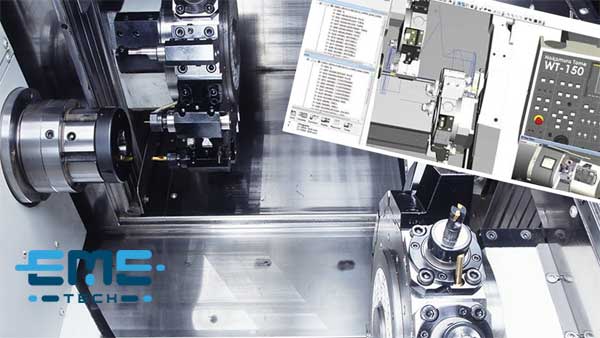

❹ CNC Turning:

Using state-of-the-art CNC equipment, machine parts are processed with exceptional speed and precision. The process involves rotating the part while the cutting tool shapes it according to the required design.

❺ CNC Milling:

This method involves cutting tools such as milling cutters, drill bits, and endmills. It is used to create precise grooves, faces, holes, and other features on the workpiece. Mounted securely on the table, the parts are shaped as the rotating tool removes material to achieve the desired form.

Quality and Expertise at EME

With a team of highly skilled engineers and state-of-the-art machinery, EME consistently delivers products that meet the highest industry standards. Our commitment to quality, efficiency, and cost-effectiveness ensures that we can fulfill the diverse needs of both domestic and international clients.

Whether you need large-scale manufacturing or custom parts, EME-Tech is the trusted partner for precision mechanical services.

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)