METAL CABINET PROCESSING

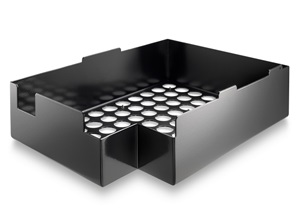

Metal cabinets are essential in both everyday life and industrial settings. Whether used for storage, organization, or housing components, these cabinets play a vital role in a variety of applications. Among the various materials used for cabinet construction — such as plastic, cardboard, wood, and metal (aluminum, steel, stainless steel) — metal cabinets stand out for their durability and strength, particularly in the electrical and electronics industries.

Metal Cabinets in Industrial Applications

In industries that deal with electrical and electronic products, the quality and design of metal cabinets are crucial. These products often require precise and well-finished enclosures that not only protect sensitive components but also enhance the products overall appearance. With modern designs becoming more sophisticated, the demand for high-quality, finely finished metal cabinets has never been greater.

While Vietnam has several factories capable of processing metal cabinets, few can match the finishing quality seen in international markets. Producing high-precision metal cabinets demands advanced machinery and a skilled workforce. This is where EME-Tech stands out.

Why EME Tech?

EME Tech has established itself as a leader in the metal cabinet manufacturing industry in Vietnam. Our company has earned the trust of major partners, both domestically and internationally, for many years. This reputation is a direct result of continuous investment in state-of-the-art machinery and equipment from renowned brands in Japan, Germany, and Korea, alongside a dedicated team of experienced engineers and technicians.

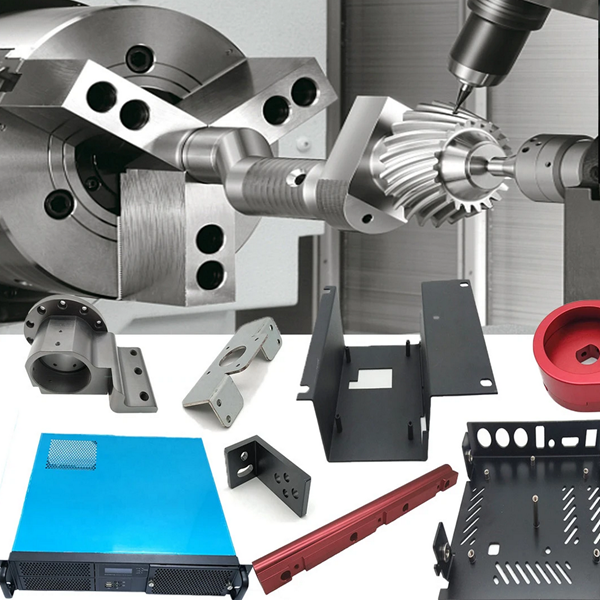

Advanced Metal Cabinet Processing Machinery

EME-Tech uses a variety of modern machines to ensure precision and high-quality production, including:

✧ CNC Laser Cutting Machine: Delivers precise cuts for a clean finish.

✧ Wire Cutting Machine: Ensures accuracy for intricate designs.

✧ CNC Bending Machine: For sharp, clean bends in metal sheets.

✧ CNC Punching Machine: Creates holes and shapes with precision.

✧ Riveting Machine: Secures parts together with durable rivets.

✧ Thread Cutting Machine: Adds threads for screws or fasteners.

✧ CNC Laser Welding Machine: Provides strong, clean welds.

✧ Grinding Machine: Finishes surfaces for smoothness and consistency.

High-Quality Production Materials

EME-Tech offers a variety of materials to suit different industrial needs, such as: Carbon Steel - Cold Rolled Steel - Hot Rolled Steel - Aluminum Alloy - Copper Alloy - Brass.

These materials ensure that the cabinets are strong, durable, and capable of withstanding industrial environments.

Versatile Box Thickness

Our metal cabinets can be manufactured with thicknesses ranging from 0.5mm to 20mm, catering to diverse applications and ensuring durability and protection for all kinds of components.

The Production Process

The process of creating metal cabinets at EME-Tech involves several meticulous steps, each carefully executed to ensure quality:

① Laser Cutting: Ensures precise dimensions and intricate details.

② Punching: Shapes and holes are created with accuracy.

③ Folding: Metal sheets are bent into the desired shapes.

④ Thread Cutting: Adds necessary threads for screws and fasteners.

⑤ Riveting: Secures different components firmly together.

⑥ Welding: Provides strength and durability to the overall structure.

⑦ Grinding: Smooths out surfaces for a clean finish.

Tight Tolerances for Precision

Our attention to detail ensures that every product meets the most stringent requirements:

➮ Laser Cutting Tolerance: +/- 0.05mm

➮ Punching Tolerance: +/- 0.01mm

➮ Folding Tolerance: +/- 0.2mm

These precise tolerances ensure that each cabinet fits perfectly and operates flawlessly in its intended application.

Strict Quality Control

At EME-Tech, quality is monitored at every step of the production process. Specialized high-precision measuring tools are used to check the dimensions and quality of each component, ensuring that the final product meets the high standards expected by our partners.

With a commitment to precision, quality, and customer satisfaction, EME-Tech continues to be a trusted name in metal cabinet processing in Vietnam. Our modern machinery, skilled workforce, and strict quality control processes ensure that every product we create stands up to the demands of both domestic and international markets.