There are 2 types of two-way entry wooden pallets including: Single-Faced Two-Way Entry Pallets and Double-Faced Two-Way Entry Pallets

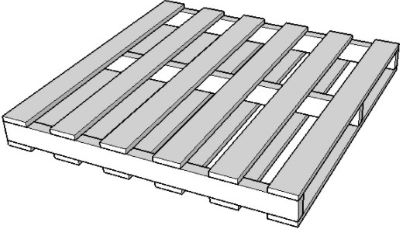

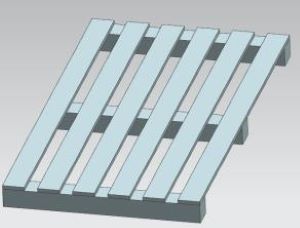

DOUBLE-FACED TWO-WAY ENTRY PALLETS = EXTREMELY HIGH DURABILITY + LOW COST + LONG-TERM INVESTMENT EFFICIENCY

These pallets support high load capacities ranging from 1,000 to 1,500 kg/pallet, offering exceptional sturdiness and durability. They are often utilized for warehouse storage, long-term use, and efficient stacking (two or three tiers), optimizing warehouse space and working seamlessly with multi-level racking systems.

Double-faced pallets typically have equal numbers of slats on the top and bottom surfaces, with slat widths ranging from 100–120 mm and wood thickness between 20–22 mm. They feature 3 or 4 load-bearing beams. The raw material usually comprises A-grade premium wood, which is treated, precisely cut, and planed on all four sides to ensure minimal dimensional tolerances of ±3 mm for the overall pallet size.

For prolonged durability in warehouses, these pallets are robustly assembled using 50 mm and 70 mm spiral nails, with 9 nails per slat. In some cases, additional steel straps are secured around the outer edges of the pallet to enhance durability and minimize damage to outer slats caused by frequent forklift use.

General Standards:

Moisture content: 20–25% or lower.

Smooth planning on all four sides of the slats.

High precision in pallet dimensions.

Strong, durable construction with minimized cracks.

Made from 100% new, square-cut wood, suitable for forklifts and racking systems. Performance is slightly less optimal for manual pallet jacks.

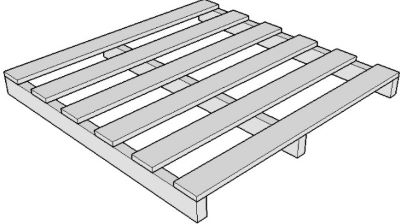

SINGLE-FACED TWO-WAY ENTRY PALLETS = LOWEST COST + HIGH DURABILITY + GOOD LOAD CAPACITY

This type of pallet is widely used and offers the most cost-effective solution compared to its durability and load-bearing efficiency.

While its durability is not comparable to that of pallets designed for heavy or long-term warehouse use, it provides the most affordable option and meets the requirements for short-term applications such as export packaging or single-use scenarios.

To achieve the lowest cost, these pallets are typically made from legally sourced plantation wood (B or C grade). Specifications include:

Wood thickness: 14–20 mm.

Slat width: 70–100 mm.

Three load-bearing beams.

Height: 80–100 mm, with a thickness of 30–35 mm.

Load capacity: 300–600 kg/pallet.

Defective sections of the wood are positioned inward to maintain overall aesthetic quality.

High labor efficiency: A single worker can produce 30–40 pallets per day.

If pallets and goods are stacked in tiers of two or three, 3–5 additional slats can be added to the bottom surface to distribute weight and prevent damage to the lower pallets.

General Standards:

Smooth planing to avoid splinters that could harm hands or products.

Secured with 5 mm spiral nails for stability.

Fumigated to meet ISPM15 international standards.

Dried naturally or air-dried on the surface without kiln drying.

Compatible with both manual and forklift operations.

Thoroughly inspected before dispatch, adhering to the quality standards of WPL Vietnam Wooden Pallets.

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)