LX-6000 AUTOMATIC ALUMINUM FOIL SEALING MACHINE

The LX-6000 Automatic Aluminum Foil Sealing Machine is an essential tool for sealing plastic bottle caps and glass jars. Widely used in various industries today, it features an automatic conveyor belt that ensures tight sealing, automatic cap tightening, and high productivity of up to 600 bottles per hour. Let`s explore more about this versatile sealing machine.

1. Application of the LX-6000 Aluminum Foil Sealing Machine

The LX-6000 is a top-selling machine, specifically designed for sealing aluminum foil on glass and plastic bottles. It helps prevent mold, leakage, and contamination, while also extending the shelf life of the contents. This machine is ideal for a variety of products, including:

■ Aluminum sealing film for plastic and glass bottles and jars.

■ Products such as seeds, powders, granules, liquid extracts, syrups, pills, and more.

■ Industries like food processing, pharmaceuticals, health supplements, and cosmetics.

2. Technical Parameters

| Model |

LX-6000 |

LX-6000A |

| Machine size (LxWxH) |

1120x470x590 mm |

1120x470x590 mm |

| Full capacity |

6000 bottles/hour |

6000 bottles/hour |

| Sealing diameter |

30-70 mm |

20-80 mm |

| Bottle height |

20-300 mm |

20-300 mm |

| Conveyor belt size |

1130x200x95 mm |

1130x200x95 mm |

| Conveyor belt bearing |

≤6kg |

≤6kg |

Sealing speed

|

0-10 m/s |

0-10 m/s |

| Voltage |

220V |

220V |

| Power |

1,8 Kw |

1,8 Kw |

| Machine weight |

40 Kg |

40 Kg |

| Material |

SUS 304 |

SUS 304 |

| Warranty |

1 year |

1 year |

| Origin |

Foreign countries |

Foreign countries |

3. Structure and Operating Principle

The LX-6000 consists of three main components: the induction heat sealing unit, conveyor belt, and electric control board.

■ Induction Heat Sealing Unit

This unit uses electromagnetic induction to melt the aluminum foil, bonding it securely to the bottles mouth. Four cooling fans help cool the foil immediately, ensuring a strong seal. The height of the heat sealing unit can be adjusted according to the bottles height, typically maintaining a 5mm distance between the cap and the unit.

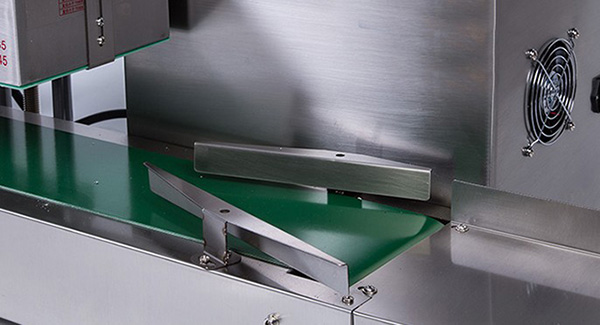

■ Conveyor Belt

Made from high-quality 304 stainless steel and PVC, the conveyor belt guides the product through the induction heat sealing unit. The speed can be adjusted based on the bottle size and type to ensure the film adheres properly to the cap.

■ Central Control Board

This electric displays and sets all operational parameters, including conveyor speed, voltage, and working current. It also features an additional fuse to prevent overload.

4. Advantages of the LX-6000 Aluminum Foil Sealing Machine

The LX-6000 offers numerous benefits, making it suitable for sealing various types of bottles and jars made of materials like HDPE, PET, PE (HDPE, LDPE), PP, PVC, PS, ABS, and glass. t can handle a wide range of products, from powders and granules to liquids and even flammable chemicals.

Key advantages include:

✓ High Productivity: Capable of sealing up to 600 bottles per hour.

✓ Tight and Secure Seal: Prevents leaks, keeps caps clean, and protects against moisture and mold, enhancing product quality. The seal can also feature a printed logo for brand identification.

✓ Durability and Efficiency: The machine is built with a sturdy structure, ensuring stable, long-term operation and energy efficiency.

The LX-6000 is an excellent choice for businesses seeking a reliable and efficient solution for their bottle and jar sealing needs.

Contact Information

Automatic Aluminum Foil Sealing Machines are available at Dong Nam. For purchasing, viewing, or testing the machine with your raw materials, please contact us:

— Hotline: +84 386.222.816 / +84 363.999.318 / +84 869.286.525

— Facebook: Dong Nam Mechanical

— Website: maydongnam.vn

— Address: 562 Phuc Dien, Nam Tu Liem, Hanoi