Sheet Metal Forming Service

Introduction

Sheet metal forming is a manufacturing process in which a piece of sheet metal is plastically deformed into a desired shape. The sheet metal is typically cut to size before being formed. The forming process can be done using a variety of tools and machines.

Nhat Nam Mechanical provides different sheet metal forming processes, each of which is used to create a specific type of shape. Some of the most common sheet metal forming processes include:

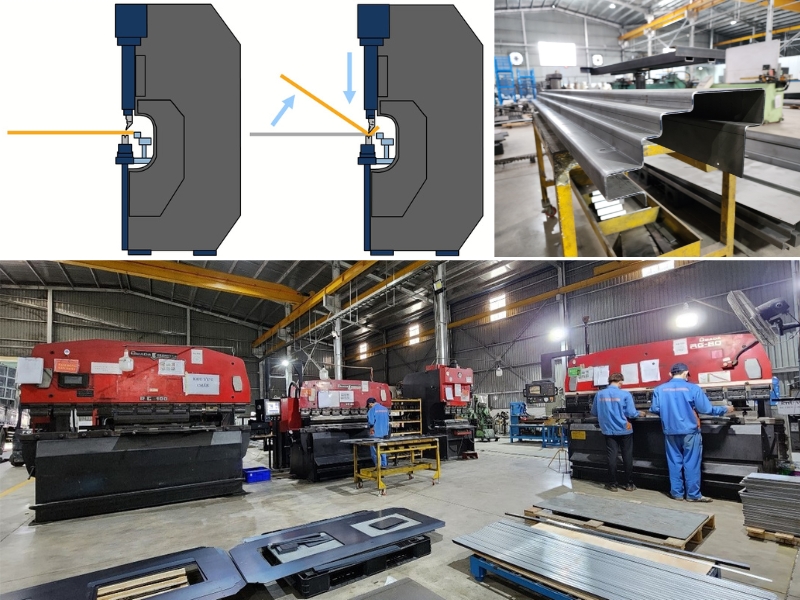

Bending: Complex parts such as Usections, channel sections of different profiles can be produced by doing multiple bends. There is no change in thickness. Good dimensional repeatability as well as close tolerances is possible with this process.

Nhat Nam uses several different types of press brakes to create formed and shaped pieces, ranging from 50 to 100 metric ton capacities. CNC operated, these systems create accurately formed parts quickly, and with the tight tolerances, our customers have come to expect.

Stamping: Usually done with a flat sheet of cold metal, Stamping, also known as pressing, is the process of creating a net shape out of metal using a tool and die surface. There are many other metal stamping processes such as embossing, bending, flanging, punching, etc. that we use to when working our customers

Depending on the need of the customer, we can use progressive dies that are typically fed material via coil of steel. After it is unwound, it is then leveled and fed into the press to a predetermined length. The entire process of feeding the metal stamping with coil of steel helps in significantly reducing production lead-times. All of the benefit of our customers.

We also perform CNC tube & pipe bending, as well as rolling services for both plate and angles. We also have the capabilities to shape pipe and tube according to orders.

Capabilities

Bending

|

AMADA RG 50

|

AMADA RG 50

|

AMADA RG 50

|

|

50 Metric Tons Capacity

2000 mm (78.8”) Bending Length

100 mm (3.94”) Stroke Length

370 mm (14.57”) Open Height

|

110 Metric Tons Capacity

2500 mm (98”) Bending Length

100 mm (3.94”) Stroke Length

370mm (14.57”) Open Height

|

110 Metric Tons Capacity

3000 mm (122”) Bending Length

100 mm (3.94”) Stroke Length

370 mm (14.57”) Open Height

|

|

AMADA SPH-60

|

AMADA SPH-60

|

AMADA SPH-60

|

|

60 Metric Tons Capacity

835 mm (32.87”) Bending Length

100 mm (3.94”) Stroke Length

570 mm (22.44”) Open Height

|

Sheet size: 127×366 cm (50”x144”)

Max. material thickness: 6.35mm (0.250”)

Max. Hole Diameter: 114.3mm (4.5″)

Punching Accuracy: +- 0.1mm (0.004”)

Press Capacity: 33 tons

Press Stroke: 31.75 mm (1.25”)

Press Speed: 350 SPM

Hit Rate (1” move): 200 HPM

Turret Rotation Speed: 40 RPM

|

Aluminum

Galvannealed Steel

Stainless Steel

Steel

|

Stamping

|

Deep drawing

|

uses a punch to fabricate deeply-recessed parts. The depth of a deep-drawn part exceeds its width, as with a cup made from a flat metal sheet.

|

|

Blanking or piercing

|

operations produce stamped parts by use of a punch and die. A press is used to advance the punch tool through a sheet into the mating die. Blanking and piercing operations typically require finishing or other secondary operations in order to remove sharp edges, burrs, or other rugged features.

|

|

Fine blanking

|

is a specialized, high-precision blanking technique in which material is sheared smoothly through its entire thickness. Fine blanking can be used to produce finished parts that do not require secondary operations.

|

|

Fourslide or multislide

|

stamping incorporates the vertical motion of a punch with horizontal die applications from multiple directions, either simultaneously or successively.

|

|

Progressive dies

|

are used in production-efficient processes where multiple stamping or forming operations are performed in successive stages or positions along the fabrication cycle.

|

|

AIDA CI-6 PRESS MACHINE

|

AIDA CI-6 PRESS MACHINE

|

AIDA CI-6 PRESS MACHINE

|

|

Press capacity: 60 ton

Stroke length: 140 mm (5.51″)

Stroke per minute: 45~85 s.p.m

Die height: 300 mm (11.81″)

|

Press capacity: 80 ton

Stroke length: 160 mm (6.30″)

Stroke per minute: 45~85 s.p.m

Die height: 320 mm (12.60″)

|

Press capacity: 45 ton

Stroke length: 150 mm (5.90″)

Stroke per minute: 45~85 s.p.m

Die height: 300 mm (11.81″)

|

|

WASINO PUX 80-KRC

|

WASINO PUX 80-KRC

|

WASINO PUX 80-KRC

|

|

Press capacity: 80 ton

Stroke length: 180 mm (7.08″)

Stroke per minute: 45~85 s.p.m

Die height: 350 mm (13.77″)

|

50 Metric Tons Capacity

2000 mm (78.8”) Bending Length

100 mm (3.94”) Stroke Length

370 mm (14.57”) Open Height

|

Aluminum

Stainless Steel

Carbon Steel

|

CNC tube & pipe bending

|

CHIYODA TUBE BENDER

|

CHIYODA TUBE BENDER

|

|

Aluminum tube: φ45xt2.0

Steel tube: φ42xt2.0

Bend axis: 300/0.6° (°/sec)

Plane axis: 450/0.6° (°/sec)

Feed axis: 1350 (mm/sec)

Processing speed: 3.0~6.0 (sec/bend)

|

Galvannealed Steel

Stainless Steel

Steel

|

Materials & Post-processing

|

|

|

|

|

Steel

CRS/HRPO

Galvanneal (GA)

Galvanized (GI)

Thicknesses available

0.025 in. - 0.787 in. (0.635 mm - 20.0 mm)

|

Stainless Steel

201

304

316

Thicknesses available

0.025 in. - 0.393 in. (0.635 mm - 10.0 mm)

|

Aluminum

1050

5052

6061

Thicknesses available

0.025 in. - 0.393 in. (0.635mm - 10.0mm)

|

Insert

For custom enclosures or parts, self-clinching fasteners are probably the most useful hardware components at a designer’s disposal. They solve a whole host of challenges when it comes to mounting components, and because of their compact design and low profile, they provide excellent aesthetics as well. Themost popular are PEMS Fasteners.

If you require a fastener we don’t stock, contact us – we’d be happy to source what you need, for added lead time and cost.

Part Marking

Part marking is a great way to add high-contrast markings, part numbers, logos, and more. The table below compares the different types of marking methods we offer.

|

Marking Method

|

Common Uses

|

Pros

|

Cons

|

|

Silk Screen

|

Graphics

Logos Text |

Color Variety

Crisp Detail Works on a variety of materials |

More costly at lower quantities

Susceptible to wear/fading over |

|

Laser Marking and Engraving

|

Graphics/Text

Part Numbers |

Extremely durable markings

Crisp Detail |

Cannot produce colored markings

|

|

Bag and Tag

|

Serialization

Part Numbers |

Very low cost

Can speed up inventory and receiving processes |

Non-permanent solution

|

Finishes

Applying a finish to your sheet cut parts can not only improve their cosmetic appeal but also provide surface protection and increased performance. Below you will find some of the post-processing options and finishes we offer:

|

|

|

|

|

|

Adhesives and Coating

|

Anodizing

|

Metal Plating

|

Pretreatments

|

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)