Sheet Laser Cutting Service

Introduction

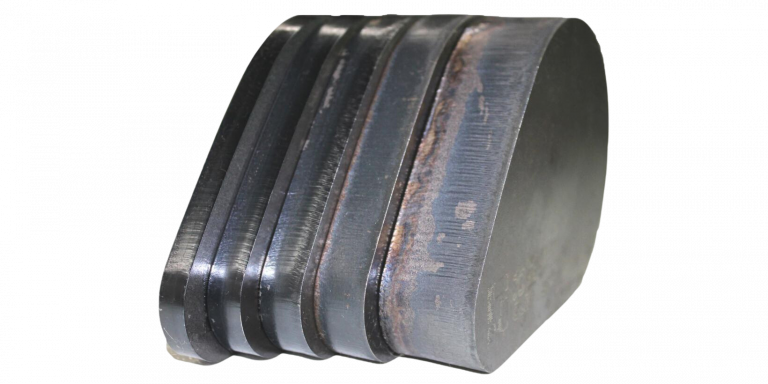

Laser cutting is a sheet metal fabrication process that uses a high-powered laser to melt or vaporize material, leaving a precise cut edge. It is a versatile process that can be used to cut a wide variety of metal thicknesses, including stainless steel, aluminum, and mild steel.

Fabricators first convert CAD and drawing data into machine code. A laser cutting machine will then precisely remove sheet material. If any assembly or post-processing is required, our manufacturers will provide turnkey finishing to the part.

Laser cutting is often used for complex or intricate cuts that would be difficult or time-consuming to make with traditional methods, such as punching or shearing.

Capabilities

Nhat Nam provides quality laser cut components to the OEM, and specialties industries. Our equipment includes a 3000-Watt Fiber Laser with twin pallets and a 6000-Watt C3 Bodor Fiber Laser with an autoload cell for maximum efficiency.

We deliver short and medium runs alike with unmatched precision.

Sizes & Tolerances

Materials & Post-processing

|

|

|

|

|

Steel

Thicknesses available

0.025 in. - 0.787 in. (0.635 mm - 20.0 mm)

|

Stainless Steel

Thicknesses available

0.025 in. - 0.393 in. (0.635 mm - 10.0 mm)

|

Aluminum

Thicknesses available

0.025 in. - 0.393 in. (0.635mm - 10.0mm)

|

Insert

For custom enclosures or parts, self-clinching fasteners are probably the most useful hardware components at a designer’s disposal. They solve a whole host of challenges when it comes to mounting components, and because of their compact design and low profile, they provide excellent aesthetics as well. Themost popular are PEMS Fasteners.

If you require a fastener we don’t stock, contact us – we’d be happy to source what you need, for added lead time and cost.

Part Marking

Part marking is a great way to add high-contrast markings, part numbers, logos, and more.

Finishes

Applying a finish to your sheet cut parts can not only improve their cosmetic appeal but also provide surface protection and increased performance. Below you will find some of the post-processing options and finishes we offer:

|

|

|

|

|

|

Adhesives and Coating

|

Anodizing

|

Metal Plating

|

Pretreatments

|

Design Guide

File Preparation Reference Sheet

File Types

Use vector files such as .DXF for 20 designs as well as for artwork such as engravings and part markings

Recommended 3D design formats:

File Optimization

Check that your design file does NOT contain:

Tolerances

Kerf

Distance Between Features

MT = Material Thickness

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)