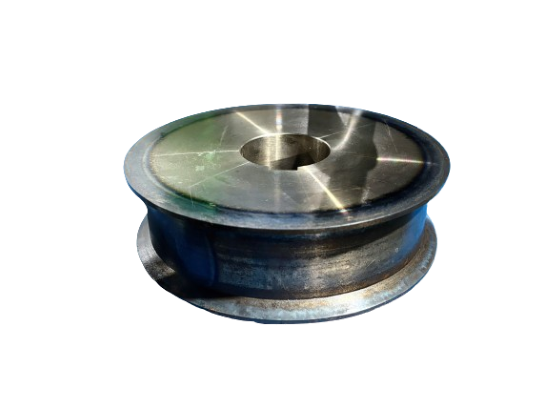

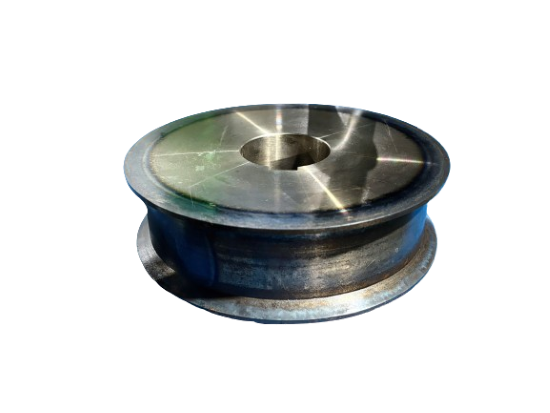

Induction hardening is a surface heat treatment process in which a metal component (typically steel) is locally heated to the austenitizing temperature by means of electromagnetic induction, followed by rapid cooling (quenching), resulting in the formation of a martensitic microstructure at the surface. To improve impact toughness and reduce residual stresses after hardening, the component is commonly subjected to subsequent tempering.

This method significantly enhances surface hardness, wear resistance, and fatigue strength, while the core retains its inherent toughness and ductility. Induction hardening is particularly suitable for applications requiring localized surface hardening, such as gears, shafts, cams, bearings, connecting rods, and other mechanical components in the mechanical engineering, automotive, and aerospace industries.

Working capacity of the induction hardening machine:

Maximum diameter: 1300 mm

Maximum height: 3000 mm

Maximum load: 3000 kg/pcs

Maximum power: 360 kVA

With a team of seasoned engineers, a production workshop equipped with state-of-the-art technology, and a profound sense of responsibility, Metal Heat consistently ensures and commits to delivering absolute trust to customers through products of the highest quality.

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)