Vacuum hardening is a steel quenching process carried out in a vacuum environment to form a martensitic microstructure with high hardness. This method was developed to meet the heat treatment requirements of high-alloy steels, tool steels, and stainless steels, where a clean surface, minimal distortion, and the avoidance of oxidation and decarburization during heating are critical.

Description

Unlike conventional quenching in gas-fired or salt bath furnaces, vacuum hardening employs a high-vacuum atmosphere combined with high-pressure inert gas cooling (commonly N₂, Ar, or He) as a substitute for oil or salt quenching media.

Applications

Vacuum hardening technology is widely applied in:

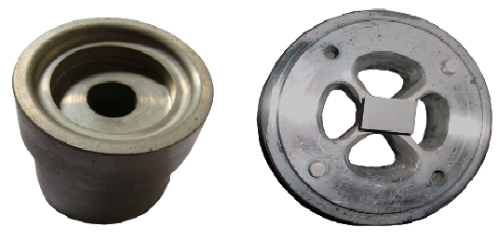

Tool steels: Cutting knives, stamping dies, plastic injection molds, precision measuring tools, drill bits, turning tools, and milling cutters.

Stainless steels and high-alloy steels: Precision mechanical components, aerospace parts, medical devices (surgical knives, surgical instruments), and electronic components.

Automotive industry: Gears, shafts, bearings, and high-load components requiring clean surfaces and high dimensional accuracy.

Energy sector: Turbine components, heat-resistant parts, and oxidation-resistant components.

Thanks to its advantages of bright surface finish, minimal distortion, and environmental friendliness, vacuum hardening has become a standard advanced heat treatment technology in modern industrial manufacturing.

With a team of seasoned engineers, a production workshop equipped with state-of-the-art technology, and a profound sense of responsibility, Metal Heat consistently ensures and commits to delivering absolute trust to customers through products of the highest quality.

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)