To help electrical wiring and cable systems in buildings, apartment complexes, factories, and industrial facilities operate more safely and efficiently, many people choose to install cable ladder systems. So, what is a cable ladder? Let us explore detailed information about this product in the article below.

1. What is a Cable Ladder?

Within cable management systems, there is a component known as a cable ladder. It is used for cables with good insulation sheathing, such as XLPE cables, and is commonly applied for cable routing and organization. Cable ladders are mainly used in environments with favorable conditions such as high-rise buildings, apartment basements, server rooms, and equipment rooms.

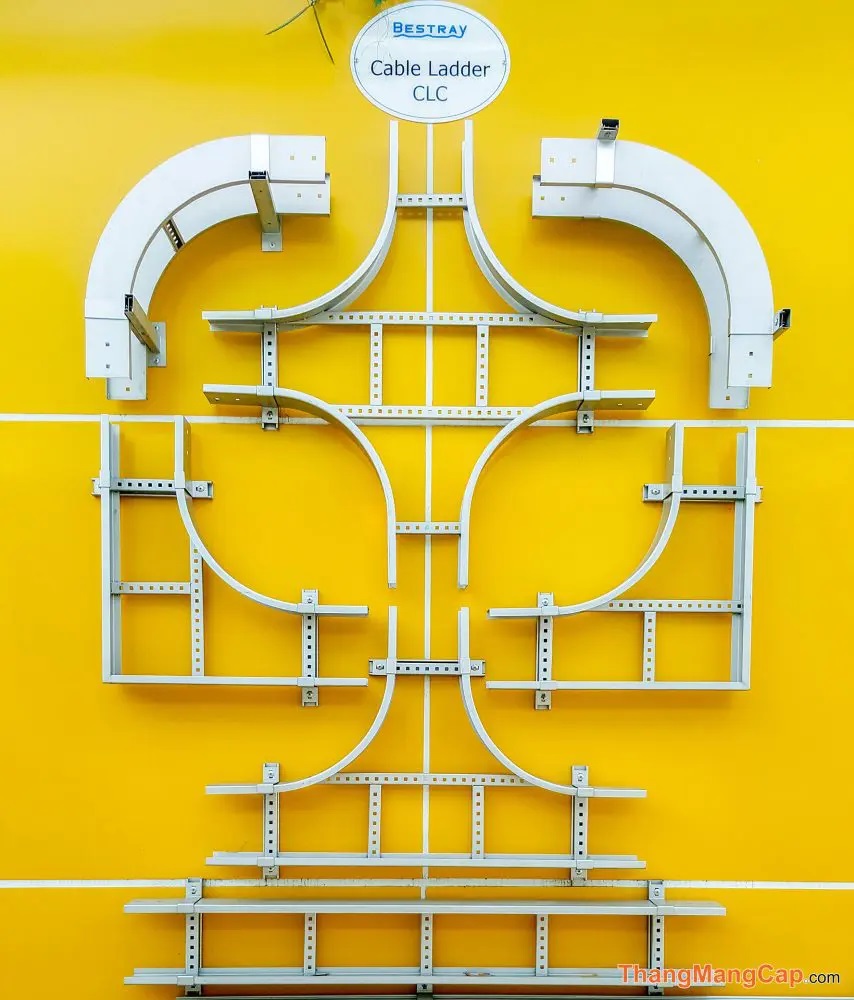

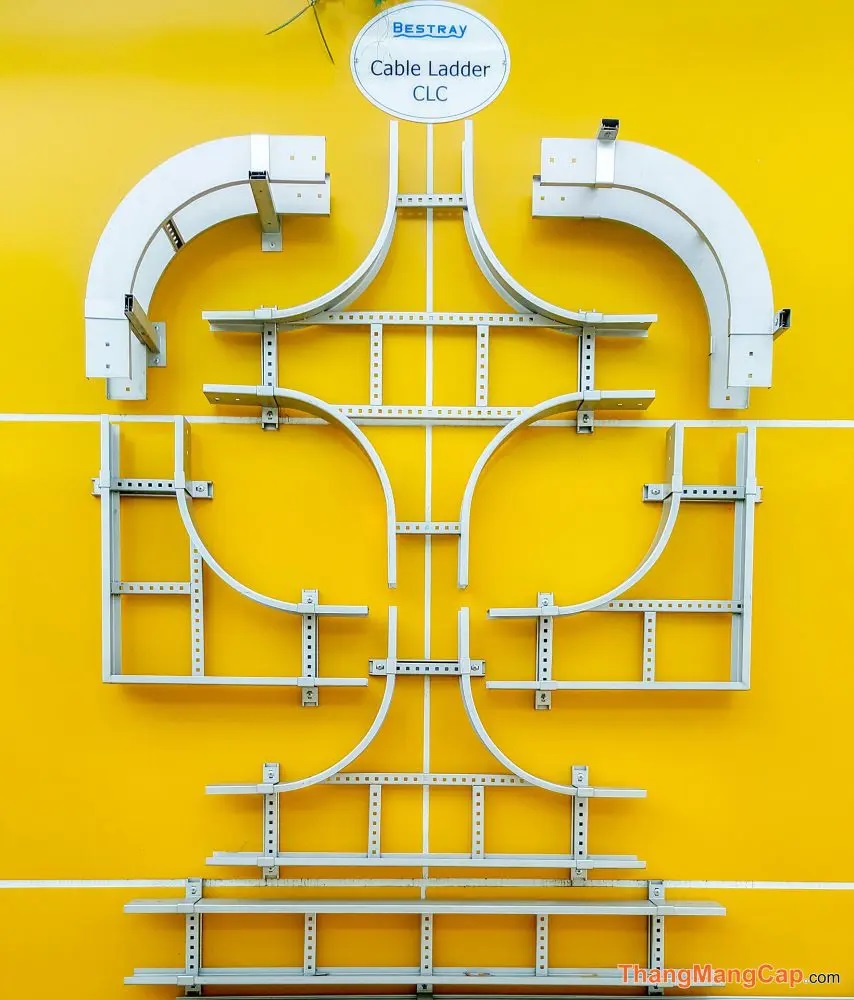

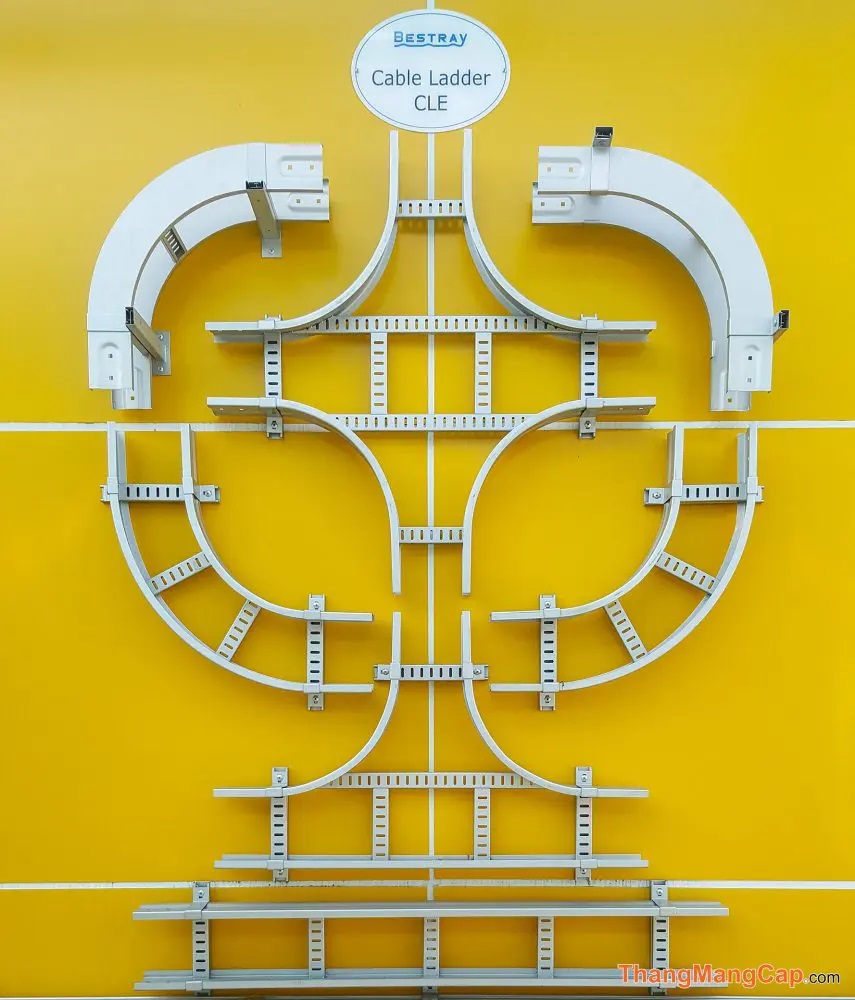

Cable ladders include the following components:

- T-shaped cable ladder (T-joint): Used to divide the cable system into three directions, which may be equal or different in length.

- X-shaped cable ladder (X-joint): Commonly used to divide the cable system into four directions with equal or varying lengths.

- Straight cable ladder: To facilitate manufacturing, installation, and transportation, straight cable ladders are usually manufactured in lengths of 2.5 mm - 3 mm. Holes are punched at every 300 mm interval for cable fastening.

- Upward elbow: An accessory used to guide a straight cable run upward.

- Downward elbow: Contrary to the upward elbow, this accessory guides a straight cable run downward.

- Horizontal elbow (L-joint or 90° elbow): Used to guide the cable ladder system to turn left or right. The two sides of this accessory may have unequal lengths.

- Cable ladder connector: Used to connect ladder sections along the same axis.

2. When and Why to Use Cable Ladders

2.1. When Should Cable Ladders Be Used?

Cable ladders are commonly used in the following cases:

- Electrical cable systems in buildings, apartment complexes, hospitals, factories, and industrial zones.

- Installation and protection of electrical cables and wires used for power distribution and communication signals.

- Cable route management in commercial and industrial services.

2.2. Why Use Cable Ladders?

Cable ladders are widely used in modern electrical systems due to their functionality and convenience. Some clear benefits include:

- Cable ladders help organize and group electrical cables and wires together, serving as the primary method to consolidate cables into a unified routing system.

- They protect cables during operation from insects, rodents, and environmental factors, thereby significantly extending cable lifespan.

- They make cable routing and installation easier, allowing for simple to complex layouts in various spaces.

- Maintenance and repair become more convenient. Previously, electrical wiring was often concealed inside walls, making repairs difficult. With cable ladder systems, faults can be quickly identified and resolved.

Overall, cable ladder systems simplify cable installation and connections while ensuring safety, providing better protection for electrical systems in buildings, apartments, factories, and industrial facilities.

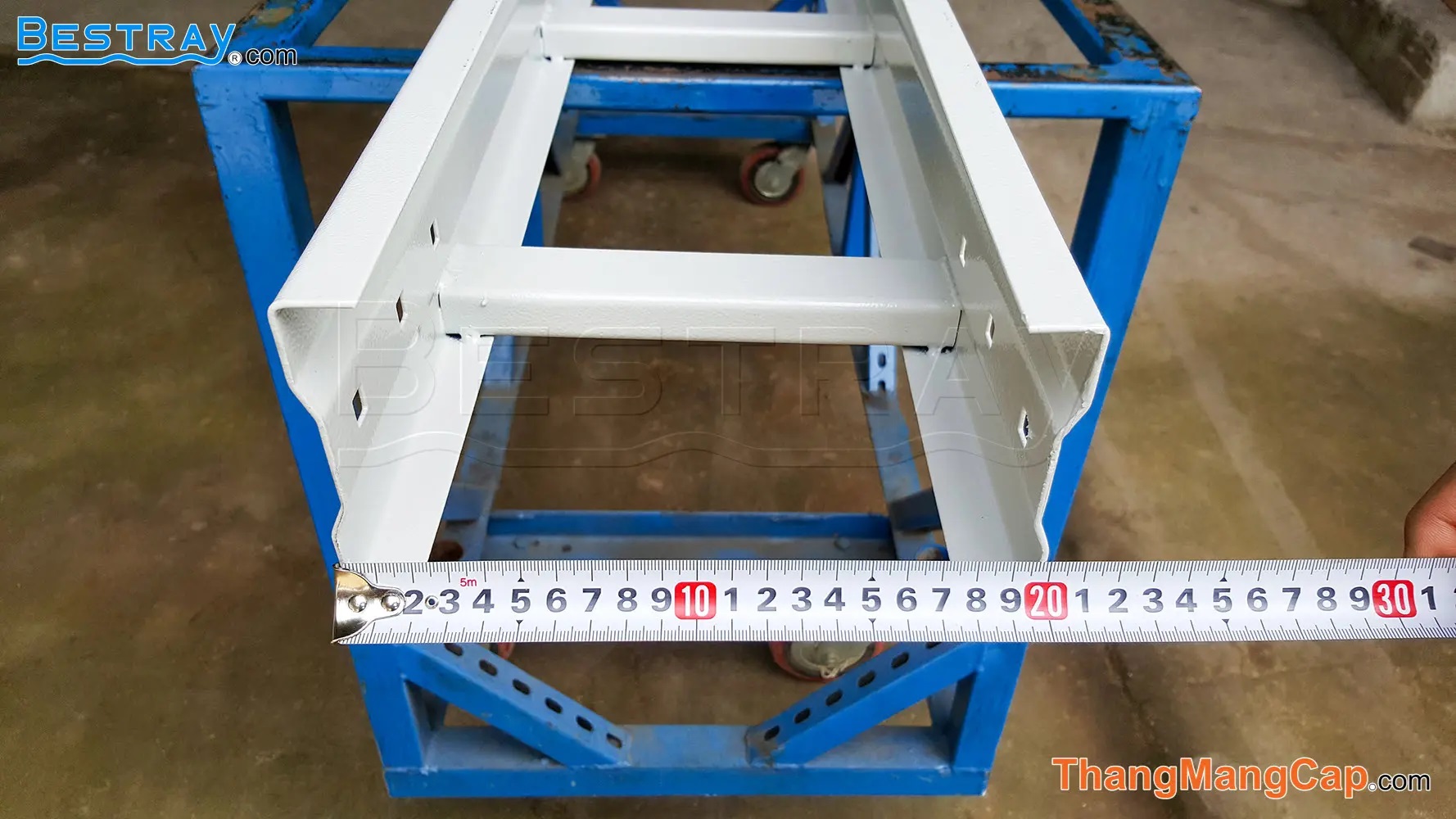

3. Cable Ladder Sizes

Cable ladders are available in various dimensions. Common sizes include:

- Height (H): 50 mm, 75 mm, 100 mm, etc.

- Width (W): 100 mm, 200 mm, up to 1000 mm

- Length (L): Standard length is 3 meters or customized according to customer requirements

- Thickness: 0.8 mm - 2.5 mm

4. Materials Used in Cable Ladder Manufacturing

4.1. Powder-Coated Cable Ladders

Powder-coated cable ladders are widely used in offices, buildings, high-rise towers, industrial zones, and apartment complexes to support electrical cable installations. They offer flexibility and convenience compared to traditional wiring methods, including surface-mounted or concealed installations.

These ladders are commonly made from stainless steel, black steel, or galvanized steel, then coated with gray powder paint or customized colors upon customer request.

4.2. Hot-Dip Galvanized Cable Ladders

Hot-dip galvanized cable ladders are coated with a layer of molten zinc over the entire surface, providing excellent protection against environmental impacts, paint peeling, and metal corrosion. They are commonly used for outdoor installations and in highly corrosive environments such as coastal areas. This ensures safe protection of electrical cables in factories, plants, and industrial facilities.

5. Cable Ladder Standards

Cable ladder systems are critical components in modern electrical installations and are subject to strict design and installation standards.

Design standards must meet technical requirements to optimize construction costs and installation time. These standards include material ion, ladder thickness, support spacing, and bending radius.

Installation standards are regulated under TCVN 9208:2012 issued by the Ministry of Science and Technology, with detailed requirements specified in Articles 6 and 7 to ensure correct procedures, technical compliance, and optimal results.

6. Cable Ladder Manufacturing Process

The cable ladder manufacturing process at Bestray includes the following steps:

Step 1: Calculate cable ladder dimensions

Step 2: Select materials and surface treatment

Step 3: Cut raw materials to size

Step 4: CNC punching

Step 5: Forming and welding

Step 6: Product inspection before surface treatment

Step 7: Surface treatment

Step 8: Final inspection, packaging, and delivery

7. Introduction to Bestray

Bestray Joint Stock Company has over 15 years of experience in supplying cable ladder and cable tray systems and has become a trusted partner for many customers. We are committed to providing high-quality products at competitive prices.

Customers may also explore other products such as cable trays, cable trunks, and cable tray accessories currently supplied by Bestray.

For further information, please contact us.

Bestray Cable Ladder Systems

Address: 180/7A, Tan Thoi 3 Hamlet, Tan Hiep Commune, Hoc Mon District, Ho Chi Minh City, Vietnam

Business hours: 7:30 AM - 5:00 PM

Phone: +84 909 089 678

Email: info@bestray.com | sales@bestray.com | quoc@bestray.com