PERFORATED CABLE TRAYS: AN IN-DEPTH LOOK

Perforated Cable Tray plays a crucial role in ensuring the safe and optimal operation of the electrical wiring and cabling system. Currently, the use of Perforated Cable Trays in factories, buildings, and apartment complexes has become very common. This system is seen as a way to protect wires and cables and allow for easy replacement if necessary.

Thanks to this, their lifespan is extended, and they are protected from failures and environmental factors. In the article below, Bestray will provide essential information for you to understand more about Perforated Cable Trays.

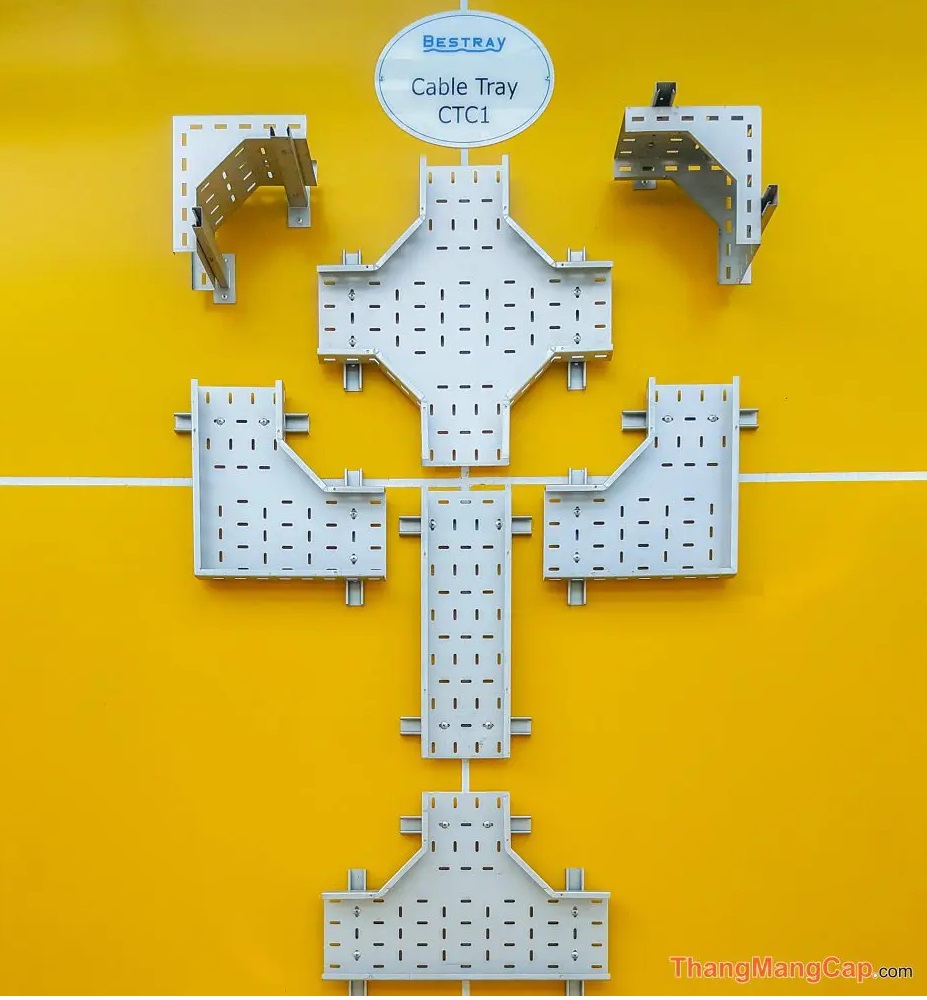

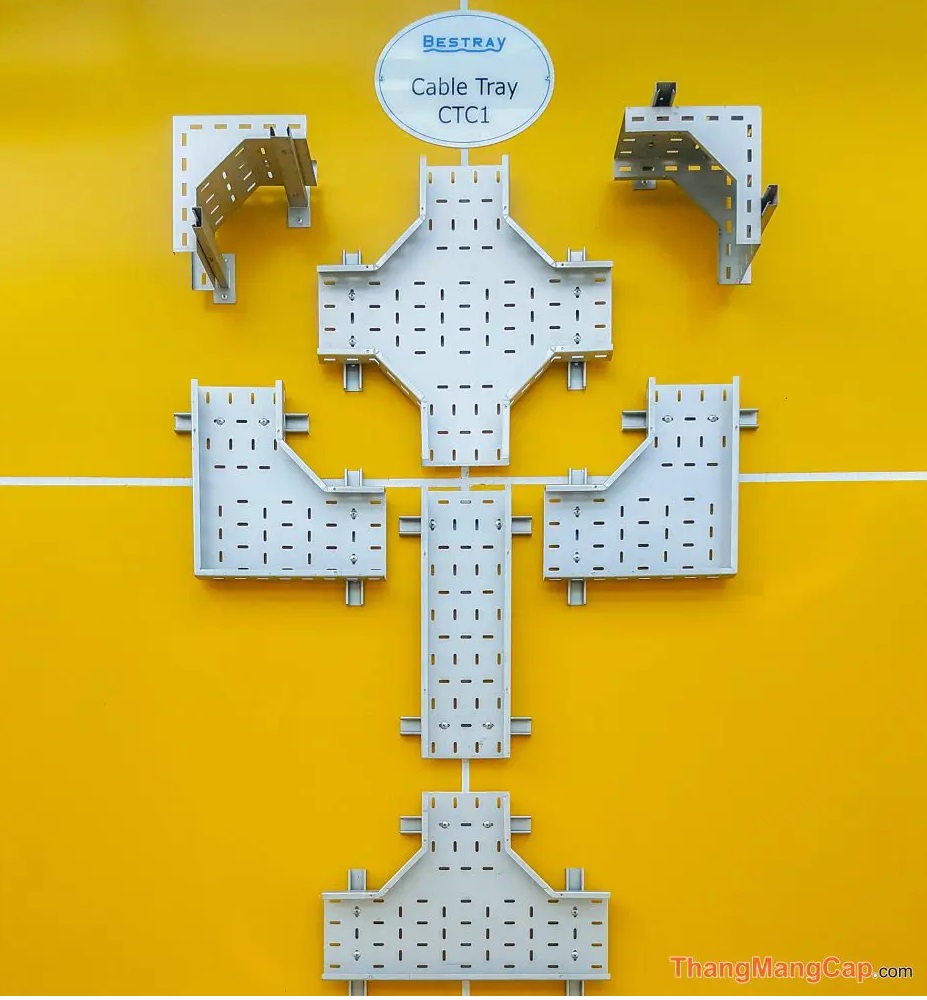

1. An Overview of Bestray Perforated Cable Trays

The Perforated Cable Tray is considered a support system for installing and protecting various types of power distribution cables, insulated conductors, and communication signal cables.

What is a Perforated Cable Tray?

The Perforated Cable Tray is designed in a rectangular box shape with perforations on the bottom and sides. Its function is to secure the conductors. Nowadays, buildings, apartment complexes, production workshops, etc., are often equipped with Perforated Cable Tray systems. This makes the process of installing, dismantling, and replacing the system much easier.

2. When to Use Perforated Cable Trays

Typically, people use Perforated Cable Trays for installation in the wiring and cabling system of apartment buildings, high-rise buildings, manufacturing facilities, etc. Their function is to protect communication signal cables or power distribution cables.

In industrial and commercial construction, the Perforated Cable Tray is often installed to help manage the system. Specifically, if you need to modify the wiring system, this installation is very convenient and useful. This is because, instead of having to install through a conduit, you simply place the new cable in the Perforated Cable Tray.

3. Perforated Cable Tray Manufacturing Materials

3.1. Aluminum Perforated Cable Trays

According to Technical Bulletin No. 13 of the Cable Tray Institute, one of the important choices when designing corrosion-resistant or outdoor cable tray systems is the material. Cable tray systems with a Hot-Dip Galvanized (HDG) finish (ASTM A-123) have been successfully used for many years. However, contractors and industrial engineers are starting to favor aluminum over hot-dip galvanizing.

The reasons are very simple. Aluminum Perforated Cable Tray systems have been shown to have many advantages in design, installation, distribution, performance, and overall cost throughout their lifespan.

Aluminum Perforated Cable Trays have a superior strength-to-weight ratio compared to hot-dip galvanized cable trays. Aluminum is also superior to HDG in that when cut in the field, it does not require cold zinc spray, which is inferior in quality compared to the original galvanizing. Therefore, when you cold-galvanize a bare metal piece, you do not restore the full strength and protection of the original coating.

In contrast, Aluminum alloy 6063-T6 has excellent corrosion resistance in a variety of environmental chemicals compared to HDG, and is sometimes referred to as marine-grade.

Aluminum can be cut or scratched and still maintain its corrosion resistance without the need for a protective coating. When Aluminum 6063-T6 trays are used with stainless steel hardware, the system can operate continuously with little or no degradation over time.

3.2. Bestray Powder-Coated Electrical Perforated Cable Trays

We supply Perforated, powder-coated Cable Trays used in industries, subway stations, office buildings, schools, etc. These types of Perforated Cable Trays are electrostatically painted and are proven to be highly durable and structurally sound. These trays are non-corrosive and can withstand high loads. They are available in various sizes and specifications.

3.3. Bestray Galvanized Electrical Perforated Cable Trays

Black steel Perforated Cable Trays that have been powder-coated. They are typically used in dry locations, such as indoors, where they are not exposed to chemicals.

There are two types: made from pre-galvanized steel (also known as galvanized sheet steel) and black steel that is hot-dip galvanized.

3.3.1. Pre-Galvanized Steel Perforated Cable Tray Products

Our company is involved in manufacturing the best Perforated Galvanized Cable Trays, widely used for electrical circulation in residential buildings, commercial complexes, institutions, industries, etc. We apply the latest technology and methods to manufacture Perforated Cable Trays. They have high tensile strength, are corrosion-resistant, and also require minimal maintenance.

3.3.2. Hot-Dip Galvanized Perforated Cable Tray Products

Bestray Hot-Dip Galvanized Perforated Cable Tray

Features:

- Low maintenance

- High durability

- High-quality Perforated Cable Tray

- Available in various shapes and sizes

- Easy to install

- Protects cables from high temperatures and harmful flames

- Ideal load bearing

- Supports a large number of network cables

- Cuts and forms smooth curved transitions around obstacles

- Quick installation using support rods

- Ideal load capacity

Applications:

- Residential apartments

- Shopping centers

- Hotels

- Business complexes

- Railways

- Airports

3.4. Stainless Steel Perforated Cable Trays

Bestray Stainless Steel Perforated Cable Tray

Features:

- High tensile strength

- Smooth finish

- Sturdy construction

- High intensity

- Dimensionally accurate trays

- Easy to assemble

- Strongly built

- Low maintenance

- High mechanical strength

- High-quality Perforated Cable Trays

- High tensile strength

- Sturdy construction

- High durability

- Cost-saving

- Supports a large number of network cables

Applications:

- Office complexes

- Train stations

- Airports

- Hospitals

- Schools

- Residential complexes

- Commercial buildings

- Industries

- Stadiums

3.5. Zam Steel Perforated Cable Trays

Perforated Cable Trays are manufactured from various materials such as:

Hot-dip galvanized steel Perforated Cable Trays are used in outdoor environments, offering high corrosion resistance.

Electro-galvanized Perforated Cable Trays are made from durable steel material. They are resistant to oxidation, corrosion, and rust, making them very suitable for outdoor projects.

Composite Perforated Cable Trays have excellent corrosion resistance. Therefore, they are suitable for use in areas with salinity, near the sea, or in environments exposed to chemicals.

4. Perforated Cable Tray Standards

Some standard characteristics of Perforated Cable Trays include:

Manufacturing Materials: Powder-coated black steel, pre-galvanized steel, hot-dip galvanized steel, Inox 201, Inox 304, Inox 316.

Standard Length: 2.4 m or 3 m.

Standard Width: 50÷800 mm.

Standard Height: 40÷200 mm.

Standard Thickness: 0.8 mm, 1.0 mm, 1.5 mm, 2.0 mm, 2.5 mm.

Popular Colors: White, orange, textured cream, or depending on customer requirements.

5. Perforated Cable Tray Manufacturing Process

Step 1: Receive and understand customer needs To ensure customers get the most satisfactory product, the first step before manufacturing Perforated Cable Trays that Bestray focuses on is clearly understanding the purpose and usage needs. From there, we can easily calculate the appropriate size and material for the product. To increase the service life and durability of the Perforated Cable Tray, we conduct actual surveys and precise measurements.

Step 2: Select the appropriate Perforated Cable Tray material Depending on the environmental conditions, we will advise on the suitable material for the Perforated Cable Tray. Some of the most commonly used materials comprise:

- Powder-coated black steel

- Hot-dip galvanized steel

- Stainless steel

In addition, other technical specifications such as length, width, and detailed thickness are needed for the design drawing.

Step 3: Cut according to the determined size In this step, Bestray proceeds to cut the steel sheets according to the predetermined Perforated Cable Tray size. The raw material for making the Perforated Cable Tray must have the required thickness, ensure quality, and be free of rust or warping.

Step 4: Perforating/Punching process Depending on the designed drawing, the product will be perforated according to requirements. Bestray uses CNC technology, a modern technology with high precision and aesthetics. Thanks to this, the product always achieves the best quality.

Step 5: Product forming After the perforating process, the product is transferred to the bending machine. The parameters for ratios and dimensions are pre-set. Thanks to this, the Perforated Cable Tray is quickly bent, welded, and firmly shaped.

Step 6: Surface inspection, pre-painting treatment After rough processing the product, all joints and welds need to be carefully checked in detail. At the same time, technical specifications such as length, width, and thickness also need to be checked accurately. Once approved, the surface treatment is performed on the rough product.

Step 7: Cleaning, washing, painting, and surface drying The rough product surface will be thoroughly cleaned according to the correct standard, depending on the surface coating technology. This is a crucial step to ensure that the Perforated Cable Tray when finished has a beautiful and durable coating over time. After cleaning, the Perforated Cable Tray surface will be coated according to customer requirements.

Step 8: Inspection, packaging, and delivery to the customer After completion, the Perforated Cable Tray will undergo a final inspection. This step is to ensure that the Perforated Cable Tray has a solid structure, meets the size requirements, is free of dents or warping, has high aesthetics, and matches the customers request. Then, the Perforated Cable Tray will be carefully packaged and transported to the customers address.

Powder-Coated Perforated Cable Tray

7. Bestray Company

Bestray Joint Stock Company specializes in manufacturing and supplying products such as cable ladders, solid-bottom cable trays, Perforated Cable Trays, cable glands, Unistrut channels, and accompanying accessories. Our products are always committed to achieving the best quality thanks to the use of modern technology and equipment.

As a result, the time and cost to complete the product are always optimized. Furthermore, with our team of experienced staff, customers will receive consulting, support, and customized solutions based on specific requirements.

With over 15 years of experience in consulting, manufacturing, and supplying cable ladders and trays, Bestray has become a trusted partner for many large and small companies and enterprises. This increasingly affirms the quality we bring to customers and helps create sustainable value.

If you have any questions about the product, click here for more details. Please contact us via Hotline +84 909089678.