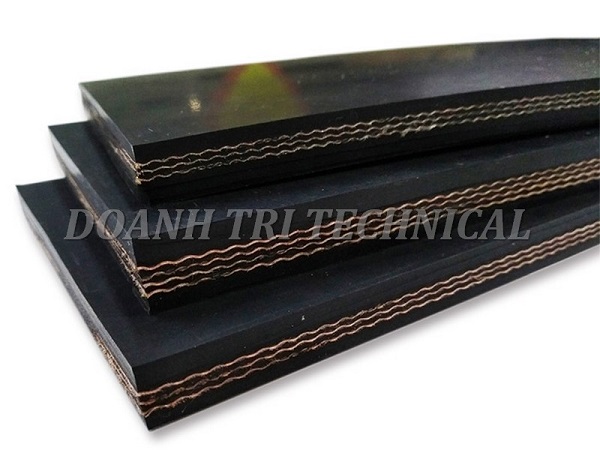

Rubber Conveyor Belt

Overview of Rubber Conveyor Belts

Rubber conveyor belts are continuous-moving belts used to transport materials or packaging from one place to another. In other words, they are solid strips made from durable materials designed to carry various items.

These belts are made from a variety of materials, including rubber compounds, leather, urethane, PVC, and even steel mesh, along with metals like stainless steel and carbon steel.

Rubber conveyor belts are widely used in various industries for material handling and transportation. They are essential in conveyor systems, where many types of rubber belts are used to transfer power from one rotating shaft to another.

These belts are commonly found in industries such as food and beverage, automotive assembly, electronics, pharmaceuticals, printing, mail sorting, tobacco, and packaging.

Types of Rubber Conveyor Belts

- Agricultural Conveyor Belts: Used in applications like transporting silage or farm equipment.

- Recycling & Recovery Conveyor Belts: Used in recycling processes to move materials for recovery.

- Food Processing Conveyor Belts: Designed for transporting food items in food processing plants.

- Packaging Conveyor Belts: Used in packaging industries to handle goods.

- Wood Processing Conveyor Belts: Used in the lumber and woodworking industries.

- Cement & Aggregate Conveyor Belts: Used in construction for transporting materials like cement and aggregates.

Advantages of Rubber Conveyor Belts

- High Mechanical Strength: Rubber belts can handle significant stress and last longer.

- High Flexibility: Can be easily bent to fit various transportation needs.

- Temperature Resistance: Suitable for extreme temperatures, both high and low.

- Abrasion Resistance: Resistant to wear and tear, making them durable.

- Chemical Resistance: Capable of withstanding many types of chemicals, which is important for harsh industrial environments.

- Durability: These belts are long-lasting and designed for heavy-duty applications.

Applications of Rubber Conveyor Belts

- General-purpose Conveyor Belts: These are used for basic material transportation or power transmission.

- Agricultural Conveyor Belts: These are for agricultural tasks such as moving silage or other farm equipment.

- Construction Conveyor Belts: Used for materials like roofing sheets or plywood, designed to carry heavy loads on construction equipment.

- Elevator Conveyor Belts: Used for vertical transportation, equipped with additional safety features and bucket attachments.

- Food and Beverage Processing Conveyor Belts: Specifically designed for food processing applications.

- Wood Processing Conveyor Belts: Designed for use in sawmills, lumber yards, and related industries.

- Mining Conveyor Belts: Heavy-duty belts used in mining operations for transporting ore, rocks, tailings, gravel, aggregates, etc.

- High-temperature Conveyor Belts: These belts are used for materials that need to withstand high temperatures.

- Inclined Conveyor Belts: Designed for transporting materials uphill or downhill.

- Packaging Conveyor Belts: Resistant to wear and tear, these belts are used in industries dealing with paper, cardboard, and packaging materials.

- Power Transmission Belts: Used for power transmission in machinery like engine belts and industrial equipment.

- Custom Conveyor Belts: Tailored for specific needs and applications.

Types of Rubber Used in Conveyor Belts

- Natural Rubber

- Neoprene Rubber

- Nitrile Rubber (NBR)

- Ethylene Propylene Diene Monomer (EPM, EPDM)

- Butyl Rubber (IIR)

- Silicone Rubber (SiR)

- Polyester/Polyamide (Nylon)

- Polyester/Cotton

- Polyamide/Polyamide (Nylon)

Sizes and Thickness

- Width: 300mm - 2500mm

- Thickness: 1.5mm - 30mm

Contact Us

📞 Phone & Zalo: +84 901 438 669

If you are looking for high-quality rubber conveyor belts at competitive prices, or need used Japanese rubber conveyor belts, please contact us for the best quotes and support.