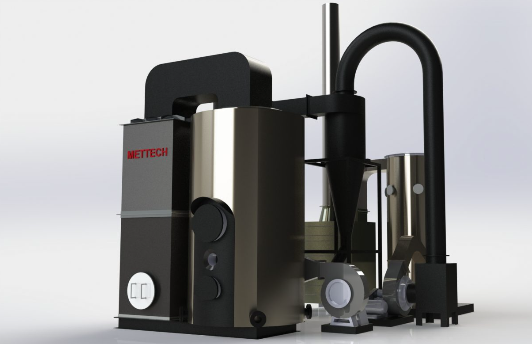

RAG-FIRED BOILER

Steam Solution for the Garment Industry

Designed as an eco-friendly steam generation solution, the rag-fired boiler addresses two critical concerns for garment manufacturers: reducing operational costs and minimizing environmental impact.

The rag-fired boiler was a traditional method used to produce yarn and fabric from natural materials like wool, cotton, linen, and silk. This process involved subjecting fabric scraps to high temperatures within a specialized chamber, or "boiler". As the temperature increased, the fabric would combust, leaving behind ash. This ash was then processed to create new yarn through spinning and twisting. While this method produced yarn with exceptional strength and fineness, it was also associated with significant fabric loss during production and difficulties in controlling the quality of the final product.

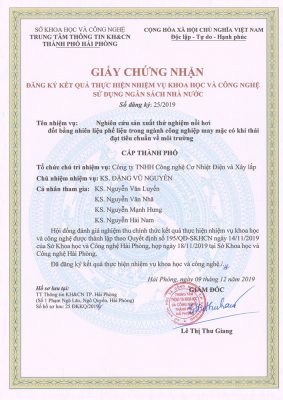

Backed by Scientific Rigor

❖ The rag-fired boiler is one of Mettech’s most innovative products, resulting from a research project approved by the Hai Phong City Science Council. This product offers textile companies a solution to generate steam using their own production waste, reducing fuel costs and waste disposal expenses.

❖ Equipped with advanced primary and secondary combustion technology, as well as a comprehensive system for filtering fine dust, treating exhaust gases, water, and odors, the rag-fired boiler is both economical and environmentally friendly.

❖ Recognized as a city-level scientific and technological research project funded and evaluated by the Hai Phong City Department of Science, this product has been developed with rigorous oversight.

❖ The product has been well-received by textile manufacturers due to its economic benefits and environmental advantages. The system effectively treats all pollutants, such as smoke, dust, and dioxins, generated during the combustion process.

❖ The entire rag-fired boiler system was researched, manufactured, and supervised by the Hai Phong City Department of Science’s scientific council. Additionally, METTECH engaged a third party, the Vietnam-Russia Tropical Center under the Ministry of Defense, to measure and analyze exhaust gas emissions.

Trusted by the Garment Industry

Garment manufacturers have warmly received METTECH’s rag-fired boiler for its economic and environmental benefits. This innovative system doesn’t just generate steam it also addresses the pressing issue of waste management by treating pollutants such as dust and dioxins during the combustion process. With METTECH’s advanced treatment system, the boiler provides a safer alternative to traditional methods like landfill disposal or incineration.

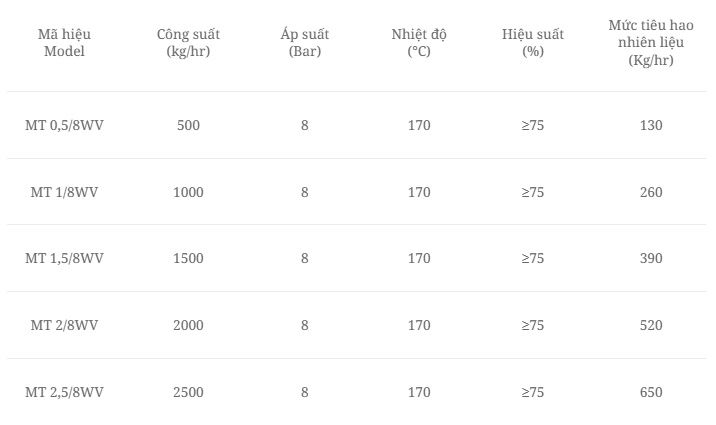

Technical Features

System Structure

The rag-fired boiler is designed with a compact, monolithic structure for easy transport and installation. Its modern design includes a fully automated PLC control system, allowing operators to manage operations with ease. The system comprises the following key components:

◈ Activated carbon absorption and chimney

◈ Alkaline absorption tower

◈ Dry dust filter

◈ Steam generator

◈ Secondary combustion chamber

◈ Primary combustion chamber

Key Benefits of METTECH’s Rag-Fired Boiler

① Cost Efficiency:

By utilizing scrap fabric as fuel, garment manufacturers can cut fuel costs by up to 70% annually compared to traditional fuel sources. Additionally, the boiler’s versatility allows for the use of other biomass fuels, such as firewood, rice husks, and wood chips, further reducing operational expenses.

② Waste Management Savings:

Instead of incurring costs for waste processing, collection, and disposal, garment manufacturers can directly use production scraps as fuel. This eliminates waste and provides a sustainable alternative to landfill or incineration.

③ Environmental Protection:

The combustion chamber, operating at 1100°C, effectively neutralizes harmful substances like dioxins. Combined with the integrated exhaust gas treatment system, the boiler significantly reduces environmental pollution compared to traditional waste disposal methods.

④ Compact and Modern Design:

The boiler system is designed for space efficiency, with a monolithic structure that is compact and easy to transport. Its fully automated PLC control system simplifies operation, allowing seamless management of the entire steam generation process.

Technical Excellence

The rag-fired boiler’s structure includes key components such as an alkaline absorption tower, dry dust filter, steam generator, and dual combustion chambers. These elements work in harmony to ensure optimal performance and compliance with TC30/BTNMT environmental standards.

The inclusion of cutting-edge features, such as activated carbon absorption and a vortex combustion chamber, further highlights METTECH’s dedication to engineering excellence.

METTECH — A Trusted Partner in Heavy Industry

With extensive experience in industrial boiler and machinery manufacturing, METTECH has established itself as a reliable partner for both domestic and international clients. Each project reflects a commitment to quality, innovation, and environmental stewardship.

Through products like the rag-fired boiler, METTECH empowers garment manufacturers to operate more efficiently while embracing sustainable practices. This innovative solution not only delivers economic benefits but also reinforces a shared responsibility for a cleaner, greener future.

By choosing METTECH, businesses gain access to advanced technology designed to optimize operations and reduce environmental impact, paving the way for sustainable industry practices.

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)