FCL, or Full Container Load, is a shipping term used in international logistics to describe a scenario where a shipper books an entire container exclusively for their goods. Here are the key points about FCL shipping:

- Exclusive Use of Container: The entire container is used by a single shipper, meaning all the goods in the container belong to one party. This reduces the risk of damage or loss since the container is not shared with other shippers.

- Cost-Effective for Large Shipments: FCL is often more economical for large shipments. When the volume of goods is enough to fill or nearly fill a container, FCL typically offers a better price per unit of cargo compared to LCL.

- Shipping Time: FCL shipments can be faster than LCL because the container goes directly from the shipper to the destination without the need for consolidation or deconsolidation, which can delay LCL shipments.

- Reduced Handling: Since the goods are not mixed with other shipments, there is less handling involved. This can lead to lower risk of damage and faster transit times.

- Flexibility in Packaging: Shippers have more flexibility with how they pack their goods in an FCL shipment. They can optimize the container space without having to worry about other shipments.

- Documentation and Customs: FCL often involves less complex documentation compared to LCL, as there is only one set of goods and one shipper. This can simplify customs clearance processes.

- Types of Containers: Shippers can choose from various types of containers (e.g., standard, refrigerated, open-top) based on the nature of their cargo.

2. Advantages of Full Container Load (FCL)

- Cost Savings on Large Volumes: FCL can be more economical for large volumes due to the fixed cost of the container.

- Reduced Risk of Damage: Less handling and no mixing with other shipments reduce the risk of damage.

- Faster Transit Times: Direct shipping routes and fewer stops speed up the process.

- Security: Higher security for goods, as the container is sealed and opened only at the destination.

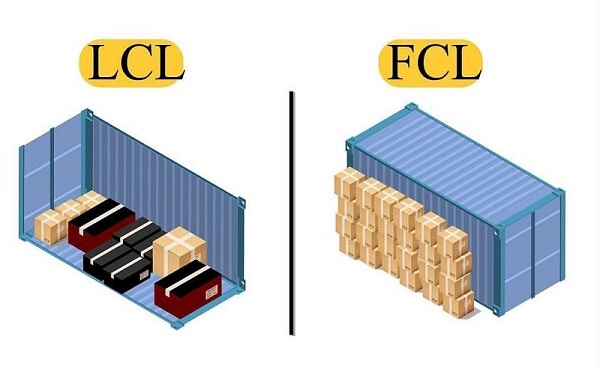

Overall, FCL is a preferred option for businesses with large volumes of goods to ship, offering benefits in cost, speed, and security, while LCL serves smaller shipments efficiently by sharing container space.

Handling Full Container Load (FCL) shipments involves several detailed steps to ensure that the containerized cargo is transported efficiently and securely from the shipper to the consignee. Here’s an overview of the FCL shipping process:

3.1. Booking and Documentation

- Booking: The shipper books an FCL shipment with a shipping line or through a freight forwarder. They provide information about the cargo, container type needed, origin, and destination.

- Documentation: Essential documents are prepared, including the Bill of Lading (BOL), Commercial Invoice, Packing List, and any required customs documents.

3.2. Container Preparation

- Container Selection: Choose the appropriate container type and size based on the cargo’s characteristics. Common types include standard, high cube, refrigerated, and open-top containers.

- Inspection: Ensure the container is clean, dry, and free of any defects or residues from previous shipments.

3.3. Cargo Loading

- Pickup: The empty container is delivered to the shippers premises or a designated loading point.

- Loading: The shipper loads the cargo into the container. Proper packing and securing are crucial to prevent damage during transit. Using pallets, dunnage, and securing straps helps stabilize the cargo.

- Sealing: Once the container is fully loaded, it is sealed with a high-security seal. The seal number is recorded on the shipping documents.

3.4. Transportation to Port

- Inland Transport: The sealed container is transported to the port of departure by truck or rail. The shipping line or freight forwarder arranges for this inland transportation.

- Port Entry: Upon arrival at the port, the container undergoes an inspection and documentation check before it is allowed entry into the port terminal.

3.5. Export Customs Clearance

- Customs Documentation: The shipper or their customs broker submits the necessary export documentation to the customs authorities.

- Inspection and Clearance: The cargo may be subject to inspection by customs authorities. Once cleared, it is ready for loading onto the vessel.

3.6. Loading onto Vessel

- Terminal Handling: The container is moved to the designated storage area within the port terminal.

- Loading: The container is loaded onto the assigned vessel based on the stowage plan. The vessel’s crew ensures the container is properly secured for ocean transport.

3.7. Ocean Freight

- Voyage: The vessel transports the container to the destination port. During this phase, the shipper can track the shipment using the container number or other tracking information provided by the shipping line.

- Communication: The freight forwarder or shipping line keeps the shipper updated on the shipment’s status.

3.8. Arrival at Destination Port

- Unloading: Upon arrival at the destination port, the container is unloaded from the vessel and moved to the terminal’s storage area.

- Import Customs Clearance: The consignee or their customs broker submits the necessary import documentation to the customs authorities for clearance.

3.9. Import Customs Clearance

- Documentation Review: Customs authorities review the import documents and may inspect the cargo.

- Duties and Taxes: The consignee pays any applicable duties and taxes. Once cleared, the container is ready for pickup.

3.10. Final Delivery

- Inland Transport: The sealed container is transported from the port to the consignee’s premises by truck or rail.

- Unloading: Upon arrival at the consignee’s location, the container is unloaded. The consignee checks the cargo for any damages or discrepancies.

- Return of Empty Container: After unloading, the empty container is returned to the designated depot or the shipping line.

3.11. Post-Delivery

- Feedback and Resolution: Any issues or discrepancies noted during the process are resolved. The shipper and consignee can provide feedback on the service quality.

- Documentation: Final documentation, including proof of delivery, is completed and provided to the shipper and consignee.

❖ Key Considerations

- Cost: FCL is typically more cost-effective for larger shipments as the shipper pays a flat rate for the entire container.

- Time: FCL shipments are generally faster compared to LCL since there are fewer steps involved in handling and processing.

- Risk Management: Proper packing and securing of cargo are essential to prevent damage during transit.

By following these steps, FCL shipments can be handled efficiently, ensuring the cargo reaches its destination safely and on time.