WASTE TRANSPORTATION AND TREATMENT

I. Collection, transportation and storage

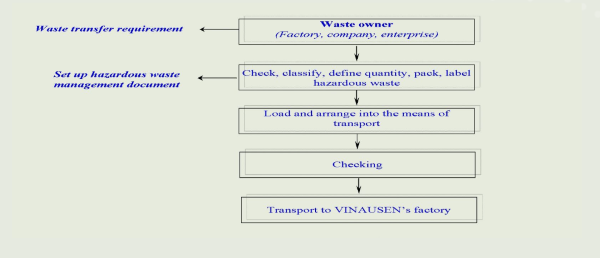

1. Process of waste collection and transportation

After the customer contact VINAUSEN to collect and transport waste, our staff will come to receive waste. Our staff will inspect the packing, labeling and storing waste in according to hazardous waste management policies.

Depending on the composition, characteristics and properties of waste, waste will be stored in different devices for the safe transporting and avoid scattering or leaking waste:

- The solid waste (such as mops, gloves contaminated lubricants, chemicals, solvents, packages contaminated chemicals, powder waste, edge boards, electronic circuit boards waste, etc) will be contained in the PE bags, fabric bags or container.

- The lubricating oil, solvents, chemicals will be stored in plastic or iron containers.

- The type of waste water, liquid sludge is contained in tanks and transported by tank truck.

After checking waste that has been classified and stored in regulations, we will weight to determine the amount of waste and loading onto the trucks. The owner shall make hazardous waste document following forms prescribed by the Ministry of Natural Resources and Environment. After finishing loading waste, our staff will check again to ensure the safety of waste arrangement on the truck before transporting them to the treatment plant in prescribed route.

The waste transporters are regularly trained about the emergency response measures. In addition, VINAUSEN regularly maintains vehicles, equipments and safety-clothes to ensure the safety of collecting and transporting process.

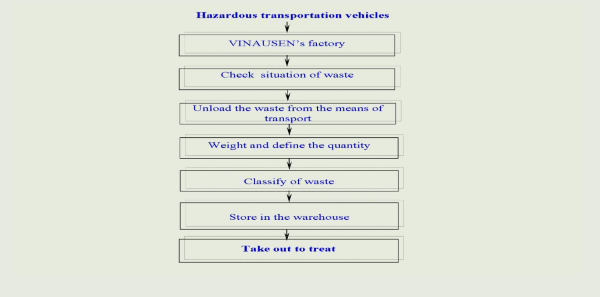

The waste after transporting to Treatment Plant will be checked, unloaded from vehicles complied with Storing processes below:

2. Process of waste storage

After transportation to the treatment plant, the waste will be inspected to ensure that no disturbances of the waste have occurred.

If waste is not disturbed, our classification team will compare with hazardous waste management documents to identify the type of hazardous waste and unload from vehicles. If the waste is disturbed, they will be unloaded and primarily classified following with hazardous waste management documents. After that, warehouse officer will record the quantity of waste.

After getting general information, wastes will be classified and be packed following VINAUSEN processes in other to be convenient for treating by our Classification team. Wastes are classified in different groups corresponding to the treatment method for each type of waste: incinerating, solidifying, recycling, etc.

After classifying process, waste will be stored in warehouse at regulated areas, and will be treated according to certain methods.

II. Methods of treatment

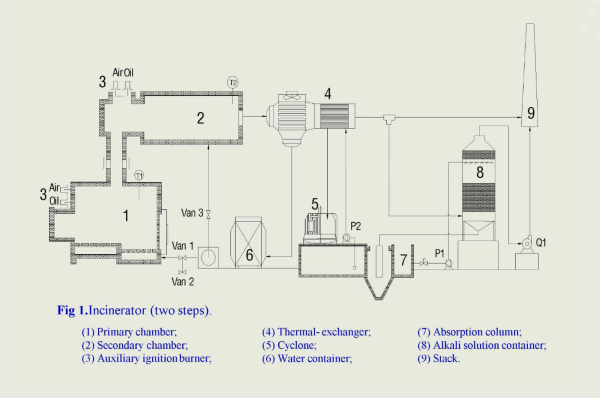

1. Incineration method

The waste will be put into the incinerator in batches, the fuel used for burning is DO oil. At the primary chamber, fuel will be sprayed into the incinerator through the burner to burn the waste and the temperature is always maintained the temperature at (550 - 6500C).

Gas generated from the primary chamber will be directed through the secondary chamber to burn the remaining components in the exhaust gas at a higher temperature (about 1000 - 1,2000C). DO oil fuel is also injected to maintain the temperature. Generated gas will be directed through a heat exchanger to reduce the temperature to below 3000C to avoid the formation of Dioxin/Furan toxins.

After being cooled down, will be guided through the absorber, with ceramic gaskets inside. The contact process between the gas phase and the liquid phase (NaOH solution), acid gas components such as HCl, HF, COX, SOx, NOx, dust... will removed from the exhaust gas before being discharged. The absorption solution is recirculated and regularly supplemented with NaOH to ensure the correct concentration for the treatment process.

Periodically, the solution will be discharged into the wastewater treatment system and replaced with new solution. The heat generated from the treatment process is used to dry waste and sludge to limit heat emission into the environment and save fuel for the treatment process.

Ash residue generated from the burning process will be solidified before being safely buried.

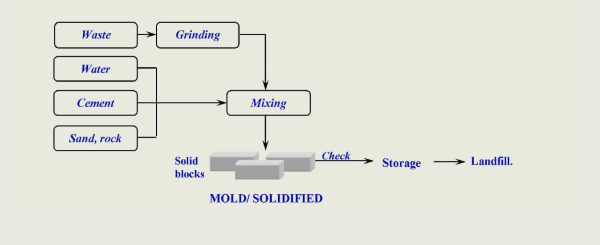

2. Solidifying method

Before the solidification process, the material must be crushed to the appropriate size, then put into the mixer in batches. Additional substances such as cement, sand, mixing polymers are added to perform the dry mixing process, then continue to add water to perform the wet mixing process. The mixing process helps the ingredients to mix evenly and form a homogeneous mixture. After the required mixing time, the mixture is added to the cube mold. After 28 days of solid mass retention, solidification occurs and complete isolation of contaminated components.

The solid block will be tested for compression resistance, leak potential and carefully stored in the warehouse before being transported to the landfill.

3. Wastewater treatment

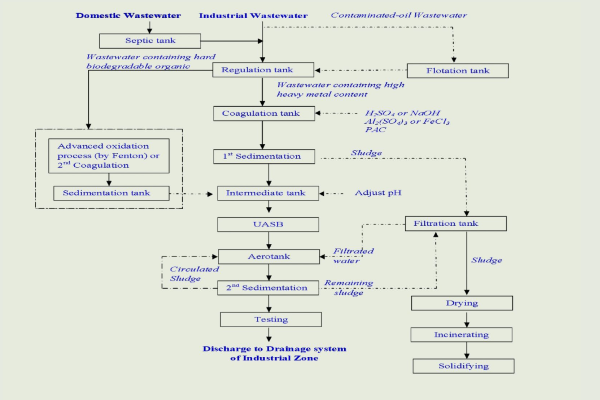

All types of wastewaters are classified and stored in separate containers. These are simple steps but very convenient for the next stages of the processing process, saving costs and optimizing technical processes, including the following items:

- Wastewater contains organic substances that are difficult to biodegrade.

- Wastewater contains high levels of heavy metals.

- Oil-contaminated wastewater.

The wastewater treatment system at the factory is operated in batch form. In each batch, wastewater is led into the regulation tank to stabilize the flow and concentration of wastewater before being discharged to the next stages.

For oil-contaminated wastewater, the first step is to separate the oil by pressure flotation before passing through the conditioning tank. The wastewater treatment process is compiled according to the following methods:

- Mechanical treatment: sedimentation, filtration, separation and flotation.

- Chemical and physical treatment: flocculation.

- Chemical treatment: oxidation at a higher level.

- Biological treatment: anaerobic (UASB), aerobic and nitrogen treatment in batches with aerobic activated sludge.

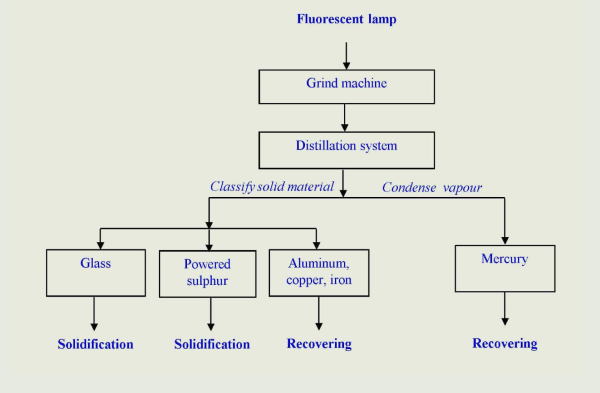

4. Fluorescent Lamp treatment

Please contact us through our hotline or send us an e-mail for more information. We are very pleased to cooperate with you!