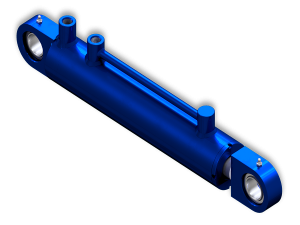

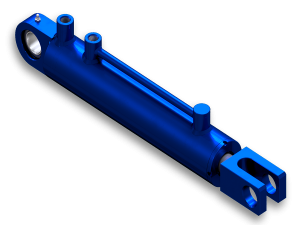

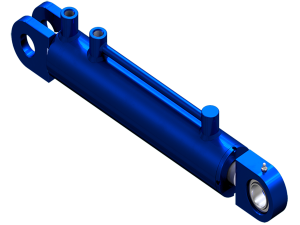

HYDRAULIC CYLINDERS FOR CONSTRUCTION VEHICLES

Hydraulic cylinders for construction vehicles typically feature a robust cylindrical design, capable of handling heavy loads and offering high durability.

Structure of Hydraulic Cylinders in Construction Vehicles

1. Cylinder Barrel

• The outer cylindrical housing, made of high-strength steel.

• Designed to withstand high pressure and wear during operation.

• The inner surface is finely machined for smooth piston movement.

2. Piston & Piston Rod

• Piston:

o Fitted inside the cylinder barrel.

o Equipped with seals to separate the two oil chambers (rod side and cap side).

• Piston Rod:

o Connected to the piston and extends outside the cylinder.

o Transmits force outward, often chrome-plated for corrosion and wear resistance.

3. Seals & Gaskets

• Rod Seal: Prevents oil leakage.

• Piston Seal: Blocks oil flow between chambers.

• Wiper Seal: Keeps dirt and debris from entering the cylinder.

• Made of synthetic rubber, polyurethane, or PTFE for durability.

4. End Caps (Head & Base)

• Head Cap:

o Features a hole for the piston rod.

o Houses the rod seal.

• Base Cap:

o Mounted to the vehicle frame or working equipment.

o Acts as the cylinder’s fixed mounting point.

5. Hydraulic Ports

• Allow hydraulic oil to flow in/out, generating push/pull force.

• May follow BSP, NPT, or SAE standards.

6. Tie Rods or Snap Rings

• Used to secure cylinder components, depending on the design.

7. Mounting Pins (Clevis / Eye Joints)

• Attach the cylinder to the vehicle frame or equipment (dump body, lift arm, etc.).

• Allow rotational movement during operation.

Applications of Hydraulic Cylinders in Construction Vehicles

Hydraulic cylinders are essential for powering various heavy-duty operations—enabling lifting, lowering, tilting, pushing, and pulling with precision and strength. Key applications include:

1. Dump Trucks / Tipper Trucks

• Dump Cylinders (Telescopic or Single-Acting):

o Lift the truck bed to unload materials like sand, gravel, or soil.

o Often telescopic for long stroke length while remaining compact when retracted.

2. Excavators (Backhoes, Diggers)

• Boom Cylinder: Controls the main arm’s up/down movement.

• Arm (Stick) Cylinder: Extends/retracts the arm between the boom and bucket.

• Bucket Cylinder: Opens/closes the bucket for digging, scooping, or dumping.

3. Forklifts

• Lift Cylinder: Raises/lowers the forks to handle loads.

• Tilt Cylinder: Adjusts the mast angle for load stability.

• Side Shift Cylinder (if equipped): Moves the forks left/right for precise positioning.

4. Bulldozers

• Blade Lift Cylinder: Adjusts the blade height for grading.

• Blade Tilt/Angle Cylinder: Tilts or angles the blade for slope work.

5. Hydraulic Cranes

• Boom Lift Cylinder: Raises/lowers the crane arm.

• Boom Extension Cylinder: Extends/retracts the arm length.

• Outrigger Cylinder: Stabilizes the crane by lifting/lowering support legs.

6. Graders, Drills, Pile Drivers, etc.

• Used for controlling attachments like blades, drill heads, or compactors.

• Ensures precise and flexible operation in various construction tasks.