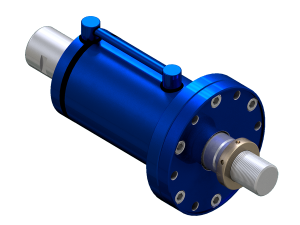

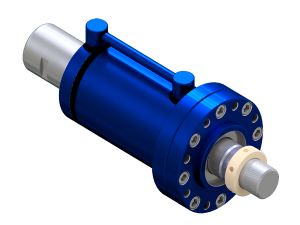

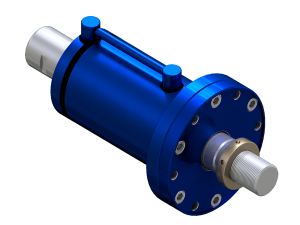

HYDRAULIC ROTARY CYLINDER

A hydraulic rotary cylinder (also called a hydraulic rotary actuator) is a device that uses hydraulic power to generate rotational motion (instead of linear motion like a standard cylinder). It is highly useful in applications requiring angular rotation, such as robotic arms, rotary table mechanisms, or rotating workpiece clamps.

1. Key Features of Hydraulic Rotary Cylinders

|

Feature

|

Description

|

|

Rotational Motion

|

Instead of pushing/retracting, the cylinder produces angular rotation, typically 90°, 180°, 270°, 360°, or continuous rotation.

|

|

High Precision & Torque

|

Uses hydraulic pressure to deliver high torque and precise speed control.

|

|

Compact Design

|

Ideal for automation systems or robotics with limited space.

|

|

Bidirectional Operation

|

Can rotate in both directions (clockwise/counterclockwise, up/down, etc.).

|

2. Basic Structure of a Hydraulic Rotary Cylinder

Depending on the type, the structure may vary, but it generally includes the following main components:

★ A. Cylinder Body (Housing):

• Houses the entire drive mechanism.

• Made of high-strength metal, sealed to contain pressurized oil.

★ B. Piston or Rotary Vane:

• Two common types:

1. Rack-and-pinion piston: A linear piston drives a gear, converting motion into rotation.

2. Vane type: One or two vanes inside a pressure chamber rotate when oil is applied, directly generating rotational motion.

★ C. Output Shaft:

• Connects to the rotating equipment.

• Directly bears the torque load.

★ D. Seals & Bearings:

• Prevent oil leaks, reduce friction, and extend service life.

3. Applications of Hydraulic Rotary Cylinders

Hydraulic rotary cylinders are highly versatile, especially in systems requiring controlled rotation where electric motors are impractical or undesired. Below are the most common real-world applications:

- Robotic Gripping & Rotation (Industrial Robots, Robotic Arms)

• Used in welding robots, pick-and-place robots, and automated handling systems.

• Enables precise gripping, rotating, and positioning of workpieces at exact angles (90°, 180°, 360°).

- Construction & Heavy Machinery

• Controls bucket rotation, booms, and auxiliary arms in excavators, loaders, and cranes.

• Can tilt or rotate machine frames.

- Automated Production Lines

• Used for:

1. Rotating products to change orientation.

2. Switching between processing stages.

3. Rotating work tables.

• Common in packaging, assembly, and product inspection lines.

- Industrial Machinery

• Found in:

1. Rotary drilling machines, CNC machining centers.

2. Presses with rotating shafts, tube benders, etc.

• Delivers strong rotational force while maintaining high precision.

- Oil & Gas, Mining, and Marine Industries

• Operates large valves, drilling rigs, and lifting mechanisms.

• More durable than electric motors in harsh environments.

- Agriculture & Food Processing

• Rotates trays, mixes, or dumps materials in processing machines.

• Used in harvesters with directional control mechanisms.