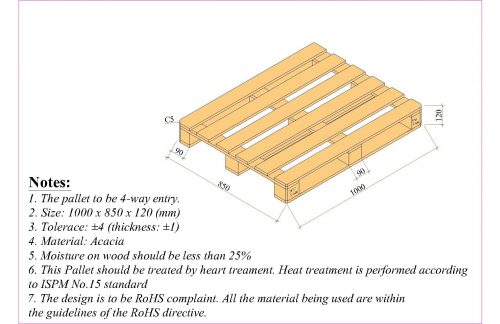

4-WAY WOODEN PALLETS

1. Product Information: Wooden Pallet

► Static Load Capacity:1500 - 2000kg

► Dynamic Load Capacity: 1000 - 1500kg

► Material: Plywood

► Lifting Directions: 4-way entry

★ Treatment: Smoothly planed on all four sides and sterilized using HT (Heat Treatment)

★ This pallet is designed for easy handling and support of goods, compatible with various types of forklifts and shelving systems in different warehouses.

Customers can choose between untreated pallets or those processed to meet international ISPM 15 standards. The wood’s moisture level is carefully controlled to suit both domestic use and export requirements, ensuring compatibility with a wide range of products placed on the pallet.

2. Advantages of Wooden Pallets

— Compared to other materials, wood is more affordable, making wooden pallets a budget-friendly choice.

— Producing wooden pallets with specific dimensions and designs incurs minimal additional costs.

— Wooden pallets can be easily repurposed for other uses without harming the environment. They can be recycled into compressed wood materials, furniture, handicrafts, or even used as fuel.

— Wooden pallets have a longer lifespan and are easier to repair compared to alternatives.

When you choose wooden pallets, you are making a cost-efficient decision. However, for exporting purposes, it is crucial to treat the wood to prevent pests and plant diseases, ensuring compliance with international regulations and avoiding the spread of agricultural diseases between countries.

At Nam A, a trusted and professional supplier, most of our wooden pallets for export are already treated to meet these international standards, giving you peace of mind and ensuring hassle-free use.

3. Nam A Wooden Pallet Production Process

❖ Step 1: Raw Material Inspection

Nam A sources wooden slats and blocks as raw materials. At this stage, all materials are inspected to remove defective pieces, such as those with rot, warping, cracks, or other damage.

❖ Step 2: Arranging Materials for Drying

The wooden slats and blocks are stacked in layers with ventilation gaps and prepared for kiln drying.

❖ Step 3: Drying Process

At Nam A, drying is a critical step in the production process. The Heat Treatment (HT) drying method is used, adhering strictly to the ISPM 15 international standard. This process eliminates risks of pests and diseases, ensuring the final product meets the highest quality standards for domestic use and export.

❖ Step 4: Four-Side Planing

The materials are planed on all four sides using advanced technology to enhance the pallets’ appearance and prevent damage to goods during use.

❖ Step 5: Cutting to Size

The wooden pieces are precisely cut to the required dimensions for each pallet type, ensuring accuracy and consistency.

❖ Step 6: Assembling the Base

The pallet bases are securely assembled in this step.

❖ Step 7: Nail Placement and Final Assembly

The pallets are assembled using industrial spiral nails, which provide maximum strength and minimize the risk of nails loosening. The nailing process strictly follows design specifications.

❖ Step 8: Labeling

Product labels, including brand names and heat treatment stamps, are applied. The paint used complies with safety standards, containing no restricted substances such as Hg, Pb, Cd, or Cr.

❖ Step 9: Finished Product Storage

The completed pallets are stored in a standard warehouse with controlled humidity and temperature. The facility is pest-free and kept clean to maintain product quality.

Nam A wooden pallets are manufactured through a well-structured, rigorous process that ensures high quality and aesthetic appeal. Each production step is carefully monitored and evaluated to deliver pallets that consistently meet customer standards. Nam A’s commitment to quality builds trust and strengthens its brand reputation among clients.

Contact us now via Hotline: +84 912040052 to get your wooden pallets!