Injection Mold Manufacturing Services

With over 15 years of experience in plastic production and mold making, Nhi Binh Plastic proudly stands as a leader in the field of precision injection mold manufacturing. We specialize in crafting molds for a wide range of products, including household plastics, pet toys, childrens toys, and technical plastic items, serving both domestic and international markets such as Japan, the USA, and Europe.

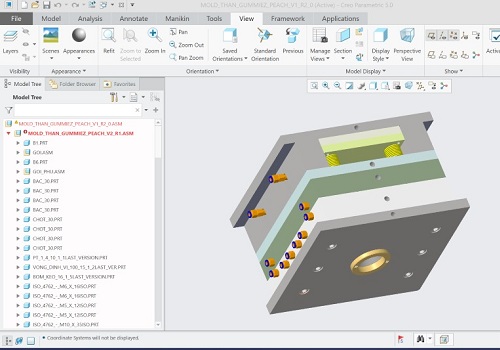

Injection Mold Designing

Our team of experienced engineers utilizes advanced CAD/CAM software to design injection molds. Detailed 3D drawings help create mold structures that simulate the final product, ensuring molds meet all technical requirements and optimize production efficiency.

Injection Mold Manufacturing Machinery

We invest in modern machinery to support our mold manufacturing process, including:

- CNC Milling Machines: Imported from Japan, high-speed, and highly precise, we use 5-axis CNC milling machines to process complex details with extreme accuracy.

- CNC Lathes: These machines ensure the precise turning of circular components, supporting the mold manufacturing process.

- Electric Discharge Machines (EDM): Used for crafting complex or angular details that are difficult to process using traditional methods, enhancing mold manufacturing precision.

- Wire Cutting Machines: Capable of cutting hard materials with high precision, producing intricate details in injection molds.

- Grinding Machines: These ensure that mold surfaces are smooth, flat, and within tight tolerances.

Injection Mold Surface Treatment

We pay special attention to surface treatments in mold manufacturing, including:

- Mirror Polishing: Ensures mold surfaces are smooth and does not affect product dimensions.

- Chrome and Nickel Plating: Enhances mold durability and creates a corrosion-resistant surface, increasing the molds value.

- Texturing and Patterning: We apply surface standards such as VDI and Yick Sang using chemical etching, sandblasting, and EDM techniques.

Quality Assurance

At Nhi Binh Plastic, we understand that precision injection molds are critical to the quality of the final product. Every mold undergoes rigorous testing by our experienced quality control team. After thorough inspection, the mold is subjected to trial injection runs to assess its performance and product quality. Based on the trial results, we make necessary adjustments before mass production begins. This ensures that all molds meet the highest standards of accuracy and production efficiency.

We guarantee that our injection molds have a lifespan of 2-3 million injection cycles, offering long-term durability and compliance with technical standards.

Partner Network

We collaborate with numerous professional partners in the mold manufacturing industry, enabling us to quickly meet large-volume mold requirements within tight deadlines, ensuring that production schedules are always maintained and customer demands are met promptly.

Technology and Professional Workforce

- We continuously update and apply advanced technologies in injection mold manufacturing.

- Our technical team and machinists work diligently to enhance their skills and meet the strictest customer requirements.

Commitment and Vision

We are committed to providing optimal mold manufacturing solutions that help customers save both time and costs while ensuring superior product quality. Our customer-centric approach drives us to continually develop and become a trusted strategic partner in the plastic industry.

Let Nhi Binh Plastic be your partner in elevating your brand and creating impressive plastic products. Contact us today for consultation and orders.