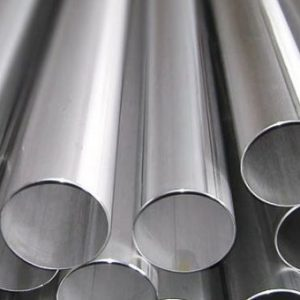

SEAMLESS AND WELDED STAINLESS STEEL PIPE

Stainless steel pipes play a vital role across numerous industries and in everyday life. Welded stainless steel pipes, in particular, allow for the production of larger diameters and lengths, making them a market leader today. However, seamless pipes are still preferred for specific applications.

Specifications of Welded Stainless Steel Pipes

- Grade: SUS201, SUS304, SUS316/L

- Surface Finish: 2B, No.1

- Standards: ASTM A312/A269, A270, JIS G3459

- Diameter: Ø17mm – Ø406mm

- Thickness: 2.0mm – 12.0mm

- Length: 6000mm

- Origin: Malaysia, Taiwan, Vietnam

Specifications of Seamless Stainless Steel Pipes

- Grade: SUS304/L, SUS316/L

- Surface Finish: 2B, No.1

- Standards: ASTM A312/A269, A270, DIN

- Diameter: Ø13mm – Ø324mm

- Thickness: Sch10, Sch40, Sch80

- Length: 6000mm

- Origin: China, India

Advantages of Stainless Steel Pipes

Stainless steel pipes are highly resistant to corrosion and feature a superior surface finish. These characteristics make them ideal for applications requiring both durability and quality, such as food processing, pharmaceutical manufacturing, and the transport and handling of liquids, gases, and chemicals under high pressure and temperature conditions.

Their high strength makes them particularly suited for use in environments with internal pressure, such as gas pipelines, petrochemical industries, liquefied gas systems, chemical processing, energy plants, and the pulp and paper industry.

Key Benefits of Welded Stainless Steel Pipes:

- Cost Efficiency: Lower capital costs.

- Production Speed: Faster manufacturing processes.

- Consistency: Better thickness and diameter tolerances.

- Inspection: Easier internal surface inspection before production.

- Concentricity: Excellent OD/ID concentricity.

For more information or to receive tailored advice on stainless steel pipes, feel free to contact us directly.