Custom Machining Services

Custom machining is a critical service that plays a vital role in industrial production development. With years of experience, Nghia Phat is committed to providing accurate and fast custom machining services to meet diverse customer needs.

1. Materials for Custom Machining Services at Nghia Phat

Nghia Phat is equipped with a wide range of machines and tools to handle various materials for custom machining. Below are the materials we work with:

1.1 Metal Materials for Custom Machining

❖ Common Metals:

- Iron: Raw iron

- Cast Iron: Ductile iron, gray iron, white iron, and more

- Steel: SUS304, SUS400, SUS420, SUS430, SUS440, SKS3, SKD61, SKD11, SCM440, S50C, S45C, S55C, etc.

- Stainless Steel: SUS201, SUS304, SUS304H, SUS304L, SUS316, SUS430

❖ Non-ferrous Metals:

- Aluminum: A6062, A7075, A5052, etc.

- Copper: Red copper, copper alloys such as brass (LCuZn30, LCuZn20Pb1), bronze (aluminum bronze, tin bronze, lead bronze)

- Nickel and Pecmaloy Alloys

- Tin

1.2. Non-Metallic Materials for Custom Machining

- Plastics: Thermoplastics like PE, PP, PVC, PS, PC, ABS, PA, as well as thermosetting plastics such as Epoxy (EP) and Phenol (PF)

- Rubber: Synthetic rubber, heat-resistant rubber, EPDM rubber, and more

- Wood: Various types of wood based on customer specifications

2. Custom Machined Products

Custom machining is highly applicable across industries such as automotive, healthcare, aerospace, military, and interior design. Therefore, the products we manufacture at Nghia Phat are diverse and versatile. We take pride in our ability to meet every custom machining requirement for both businesses and enterprises.

2.1. Jigs and Fixtures

Jigs and fixtures are positioning tools used to secure workpieces during machining to ensure high precision. These include machine part fixtures, product molds, and more.

At Nghia Phat, we guarantee that all jigs and fixtures are fabricated according to design specifications and delivered with precision. We offer a wide range of fixtures, including welding jigs, milling jigs, turning jigs, drilling jigs, injection molds, blow molds, and more.

2.2. Machine Parts

Machine parts are essential components for assembling machinery and equipment. Nghia Phat ensures the precise machining of machine parts to meet exact specifications, from dimensions to shapes, including the smallest details. We focus on delivering smooth surfaces with minimal imperfections, ensuring durability and functionality for the final products.

2.3. Molds

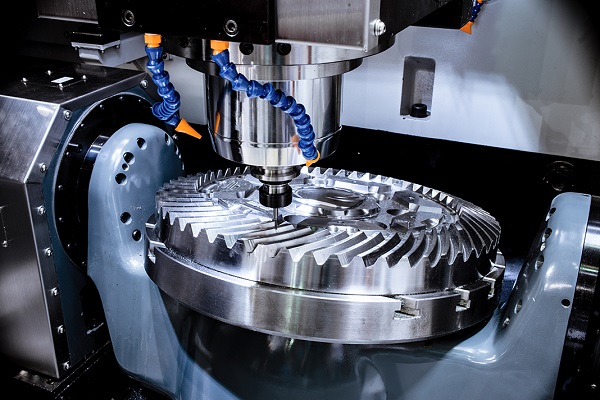

We specialize in custom machining molds that are manufactured to design specifications and rigorously tested for accuracy. Whether basic or complex, our molds are crafted using CNC machines under the strict supervision of our engineers, ensuring top-notch quality for various production needs.

2.4. Support Equipment

Nghia Phat also manufactures custom support equipment, including tool cabinets, industrial roller conveyors, folding ladders, and more. All products are designed to meet durability standards and functional requirements, ensuring reliability and quality.

3. Why Choose Nghia Phat for Your Custom Machining Needs?

With years of experience and a strong track record of collaborating with both large and small businesses, Nghia Phat offers several advantages that set us apart.

3.1. Complete CNC Machining Equipment

To meet customer demands for high-precision custom machining, Nghia Phat is equipped with a diverse range of machines, particularly CNC systems, for precise machining according to design specifications. Our CNC machining equipment includes:

- CNC Lathes

- CNC Drilling Machines

- CNC Boring Machines

- CNC Grinding Machines

- CNC Laser Cutting Machines

- CNC Milling Machines

- CNC Planing Machines

3.2. Highly Skilled Engineering and Machining Team

In addition to investing in state-of-the-art equipment, Nghia Phat places great importance on its workforce. Our team consists of highly skilled engineers (including master and Ph.D. level professionals) and experienced technicians who have a wealth of expertise in machining.

3.3. Scientific and Efficient Machining Process

Our commitment to professionalism is another key reason customers choose Nghia Phat for their custom machining needs. Our process is structured for efficiency and convenience:

- Customer Request: We begin by thoroughly understanding the customer requirements.

- Consultation and Quotation: Our team advises the best machining solutions and provides an accurate quote.

- Finalizing the Machining Plan: The customer approves the final machining plan.

- Machining and Quality Control: We execute the machining process and conduct strict quality control checks to ensure the product meets all specifications.

- Delivery: Once machining is complete and quality is assured, we deliver the finished products to the customer designated location as quickly as possible.

By choosing Nghia Phat, you can trust that your custom machining projects will be handled with precision, efficiency, and care.