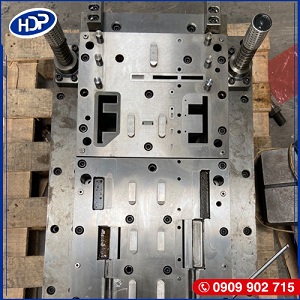

Progressive stamping dies are one of the most widely used types of dies today. This product enables the mass production of sheet metal components, producing several pieces per second, thereby reducing production costs and enhancing competitiveness.

Progressive stamping dies facilitate the rapid production of sheet metal parts in large quantities, up to several products per second. These dies are made from high-quality alloy steel, operate automatically, and feature high-precision stock feed movement.

Structure:

The structure of progressive stamping dies includes 29 key components as listed, with 4 die stations, designed based on the following principles:

The first station performs the function of punching holes and cutting rotor slots.

The second station cuts yoke slots and stator slots.

The third station cuts and forms lamination sheets and rotors.

The fourth station cuts and forms stator lamination sheets.

Lastly, it trims away burrs from the parts.

Additionally, the dies consist of other components such as the auxiliary base, lower base, upper base, stock guide plate, guide bushings, yoke punch, stator punch, rotor punch, punch shim, guide pillars, die plates, etc.

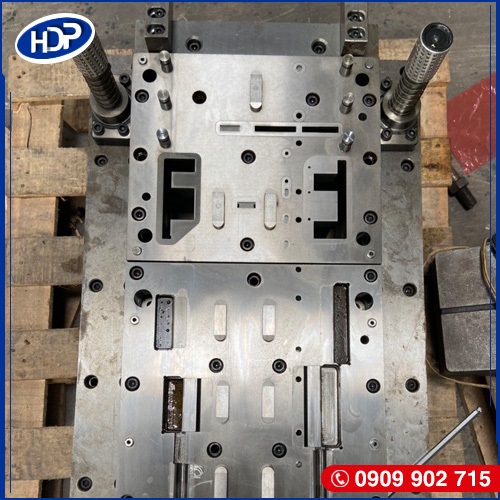

Progressive Die Machining at HDP

The design of progressive stamping dies allows for smooth and continuous automated production, bringing numerous benefits to the manufacturing process:

Enhances production efficiency through machinery automation.

Produces parts with guaranteed mechanical properties, quality, and high precision.

Increases output, while reducing production time and labor costs.

Progressive dies offer numerous benefits in production

If you are searching for a reputable provider of progressive stamping dies in Southern Vietnam, HDP Precision Engineering is the best choice. With 15 years of experience in the field of mechanical processing, HDP strives to deliver the highest quality finished products to its clients. Proudly partnering with leading global brands such as SAMSUNG, LG, MABE, GE-GENERAL ELECTRIC, NOVITA, SK AMGIC, COWAY, DAELIM, WHIRLPOOL, and more.

HDP’S COMPETITIVE ADVANTAGES:

In-house design, manufacture, and repair of dies, allowing for full control over quality and timelines.

Strict management processes from quality control through design, production, inspection, and product acceptance.

Modern machinery systems including milling machines, lathes, EDM machines, surface grinders, CNC wire cutting, CNC turning, and Japan-made Kyori terminal stamping machines.

Skilled workers and technicians, trained in advanced techniques from Japanese and Korean partners.

SALES POLICY:

Support for die setup and product output after delivery, with post-sale warranty.

Full responsibility for the maintenance and servicing of dies produced by HDP throughout their lifespan.

Contact us today for consultation on the most suitable products to meet your needs. HDP Precision Engineering looks forward to collaborating and working alongside esteemed clients!

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)