Honeycomb Paper Core

Introduction

Honeycomb paper cores are a key component in honeycomb paper products, widely used across various industries and in everyday life. Known for their durability, soundproofing, and thermal insulation properties, honeycomb paper cores have become an essential material in numerous applications.

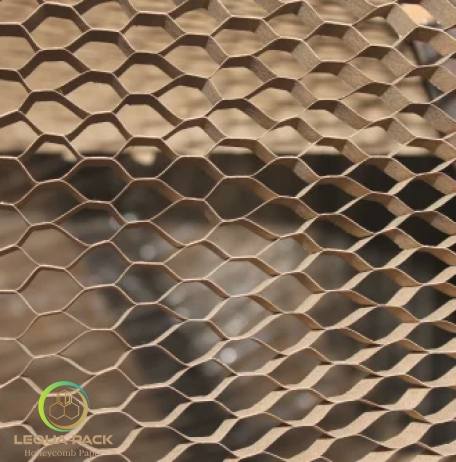

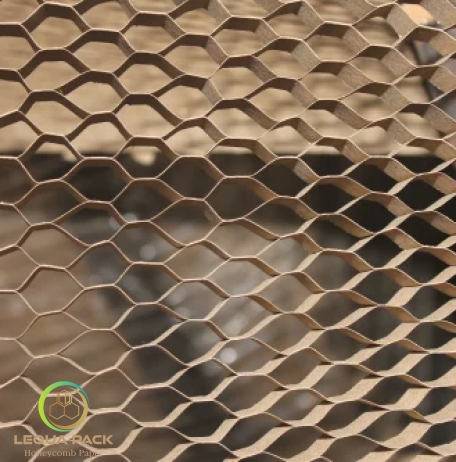

1. What is a Honeycomb Paper Core?

A honeycomb paper core is made from paper hexagons arranged side by side, resembling a real honeycomb structure. Available in different hole diameters and thicknesses, these cores serve various purposes. Made from recycled paper, honeycomb paper cores are an environmentally friendly choice that helps reduce harmful emissions. Additionally, their durability makes them a popular material for a wide range of uses.

2. Structure of a Honeycomb Paper Core

The structure of a honeycomb paper core is simple yet effective. It consists of paper hexagons arranged in a honeycomb pattern. The core design allows it to expand and contract like a fan, making it flexible and resistant to tearing. This feature enhances the core’s resilience and ease of use and installation.

3. Materials Used in Honeycomb Paper Core Production

Honeycomb paper cores are produced using recycled paper, a readily available and recyclable material that is eco-friendly. This production process supports environmental conservation and helps protect natural resources. In addition to paper, adhesives and additives are used to enhance the core’s properties, such as strength, rigidity, and moisture resistance.

4. Honeycomb Paper Core Production Process

❖ Preparing Materials

Before starting the production process, careful preparation of materials is essential to ensure the quality of the final product. Selecting the right types of paper and additives is crucial for achieving high durability and effective soundproofing and thermal insulation properties in honeycomb paper cores.

❖ Honeycomb Paper Core Production

The production of honeycomb paper cores is a streamlined, automated process carried out on modern machinery. The main steps in this process include:

- Punching Holes in Paper: Paper is fed into a punching machine to create the necessary hexagon shapes, according to the hole diameter.

- Assembling Hexagons: The hexagons are then bonded to face sheets using adhesive.

- Drying: The assembled product is dried to form the completed honeycomb paper core.

To ensure high precision and the desired strength of the product, the production process is closely monitored and inspected by industry experts.

❖ Quality Control

After production, the honeycomb paper cores undergo a quality inspection to ensure they meet customer standards and specifications. Cores that do not meet quality requirements are discarded and not shipped.

5. Advantages of Honeycomb Paper Cores

- Durability and Aesthetic Appeal: One of the standout benefits of honeycomb paper cores is their durability and visual appeal. These cores are capable of withstanding significant force and maintaining their shape even at high temperatures, making them suitable for various environments and applications. Their honeycomb-like structure also adds an attractive design element to products and projects that use them.

- Soundproofing and Insulation: Honeycomb paper cores, made from recycled paper, offer excellent soundproofing and insulation properties. They help reduce noise and effectively retain heat, which is particularly beneficial during cold winter months. Using honeycomb paper cores in construction and interior design not only enhances living conditions but also promotes energy efficiency.

- Eco-Friendly: Produced from recycled paper, honeycomb paper cores contribute to reducing harmful emissions and protecting the environment. Opting for honeycomb paper cores means supporting resource conservation and environmental protection. This makes the product a sustainable choice and a positive step towards sustainable development.

6. Applications of Honeycomb Paper Cores

❖ Door Core Applications: Honeycomb paper cores can be used as door cores to enhance both soundproofing and insulation. They not only improve the functionality of doors but also add an attractive design element to entryways.

❖ Construction and Decoration: In construction, honeycomb paper cores are used for various purposes including partition walls, tabletops, seating surfaces, and as cores in steel and aluminum doors. Their soundproofing, insulating properties, and durability make them ideal for a wide range of building and decorative applications.

❖ Other Industrial Uses: Beyond everyday and construction applications, honeycomb paper cores are also utilized across various industries:

- Electronics: Honeycomb paper cores are used to protect and insulate electronic components such as coils and printed circuit boards.

- Automotive: In automotive manufacturing, honeycomb paper cores serve as soundproofing layers within vehicles, reducing road noise and vibrations.

- Packaging: In the packaging industry, honeycomb paper cores provide protection and help maintain the shape of products during transit.

With their diverse and effective applications, honeycomb paper cores are increasingly becoming an indispensable material in many modern industries.

7. Usage Tips

- Proper Storage: To maintain the durability and quality of honeycomb paper cores, proper storage is essential. Avoid exposing the product to direct sunlight and high temperatures. Store it in a dry, cool, and well-ventilated area to prevent moisture and deformation.

- Safe Installation and Use: When installing honeycomb paper cores in construction projects or doors, follow the manufacturer’s instructions carefully. Ensure that the cores are securely and safely installed to prevent any accidents. Additionally, familiarize yourself with the features and applications of the honeycomb paper cores to ensure their effective and safe use.

Conclusion

This overview has provided detailed information about honeycomb paper cores, including their structure, production process, applications, and tips for effective ion and use. We hope this article has helped you gain a better understanding of this product and its potential applications in both professional and everyday contexts.

If you have any questions or need further clarification, please feel free to leave a comment, and we will be happy to assist you. We wish you a great experience with honeycomb paper cores!