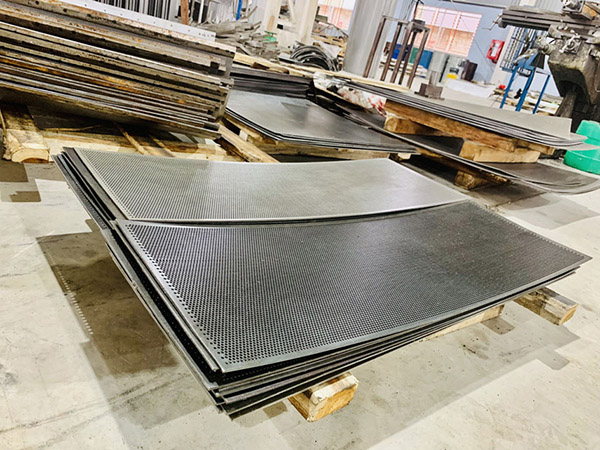

Metal Perforated Drying Screens

Introduction

In rice harvesting and processing, drying plays a crucial role in ensuring quality and extending storage life. To optimize the drying process, various types of drying screens have been developed. Among them, metal perforated drying screens stand out with several advantages over traditional options like plastic or woven screens. This article explores the features, benefits, and applications of metal perforated drying screens.

1. Rice Grain Size and Requirements

Metal perforated drying screens are designed with precisely sized and spaced holes to match the size of rice grains. This ensures that the rice is securely held while allowing the necessary airflow for effective drying. Hole sizes are typically adjusted based on the grain size and specific drying requirements of different rice types. Screens with holes that are too small may obstruct the drying process, while those with holes that are too large could result in rice falling through.

2. Advantages Over Plastic and Woven Screens

- High Durability: Metal perforated screens are significantly more durable than plastic and woven screens. They withstand heat and resist corrosion from the hot and humid drying environment, reducing maintenance and replacement costs.

- Better Heat Resistance: Metal can handle higher temperatures than plastic, allowing metal perforated screens to perform efficiently in high-temperature drying conditions without warping or damage.

- Easy to Clean: The smooth surface of metal screens is easier to clean compared to plastic and woven screens, which is crucial for maintaining hygiene and rice quality.

- Stability: The uniform and stable hole sizes in metal perforated screens provide more even airflow distribution compared to woven or plastic screens, which may deform over time.

- Customization: Metal screens can be produced in various sizes and shapes to meet the specific requirements of different drying systems. This customization helps optimize drying efficiency for various applications.

3. Roll Form Applications

Metal perforated screens can also be produced in roll form, which is particularly useful for large drying ovens. Roll form makes transportation and installation easier in large-scale industrial drying systems. Additionally, roll screens can be cut and adjusted to the specific dimensions needed for a drying system, saving time and installation costs.

Conclusion

Metal perforated drying screens offer an excellent solution for rice drying due to their high durability, heat resistance, ease of cleaning, and stability. Compared to plastic and woven screens, metal perforated screens not only provide optimal drying performance but also extend the lifespan of drying equipment. The flexibility in roll form production for large dryers further highlights the value of this solution in the rice processing industry.

BIG WORLD CO., LTD

- Tax ID: 1101924507

- Address: Lot I6-2, Road No. 9, Thuan Dao Expanded Industrial Park, Long Dinh Commune, Can Duoc District, Long An Province

- Email: daithegioilongan@gmail.com - luoithep@daithegioi.vn

- Factory phone: +84 272.3630.066

- Office phone: +84 28.6283.0405 (Accounting) - +84 942.788.188 (Sales)

- Hotline: +84 903.330.386 - +84 942.788.188 - +84 902.394.536

- Technical/Zalo: +84 947.799.099 - +84 947.888.809

Related Keywords:

- Rice drying screens

- Metal perforated screens

- Drying screen hole sizes

- Advantages of metal screens

- Comparison of metal and plastic screens

- Roll form drying screens

- Large dryer screens

- Efficient drying screens

- Heat-resistant drying screens

- Cleaning drying screens

- Durability of metal screens

- Industrial drying screens

- Corrosion-resistant screens

- Rice drying systems

- Rice processing screens

- Customizable drying screens

- Even airflow screens

- High-performance drying screens

- Rice drying screen design

- Screens for rice processing industry