GAS FLOW METER

Phuc Sang Minh (JPS) specializes in supplying high-quality gas flow meters, ensuring excellent performance and high accuracy.

1. Turbine Gas Flow Meter - TRZ2/SM-RI-X

The Honeywell Elster TRZ2 turbine gas flow meter is robustly designed for measuring gas consumption in gas distribution stations, industrial plants, or commercial users.

❖ Advantages:

- High accuracy and reliability.

- World-leading in turbine gas flow measurement.

- Standard gas measurement applications.

- Allows for repeatable measurements even under non-ideal conditions.

- Significantly reduces service time in case the measuring chamber needs replacement.

- Minimizes impact on meter performance as the measuring chamber is separate from the meter body.

For sizes larger than 6", Honeywell offers the SM-RI-X turbine gas flow meter, available up to 24".

2. Rotary Gas Flow Meter - RABO

Honeywell Elster RABO is suitable for measuring natural gases and filtered non-corrosive gases of various kinds.

❖ Features:

- Wide measurement range and compact size.

- Ensures high accuracy even at very low or fluctuating gas flows.

- Combines tested and proven features from Elster-Instromets previous rotary gas meter products.

- Provides a range of future-oriented functionalities.

3. Turbine Gas Flow Meter - Quantometer Q/QA/QAe

Used for measuring natural gas, air, methane, nitrogen, and other non-corrosive gases.

❖ Industries: Heavy and light industries, oil refining, steel, electricity, mining, heating systems.

❖ Functions: Measures gas flow distribution at plants, gas volume input for consumption control, burner monitoring, boilers, furnaces, etc.

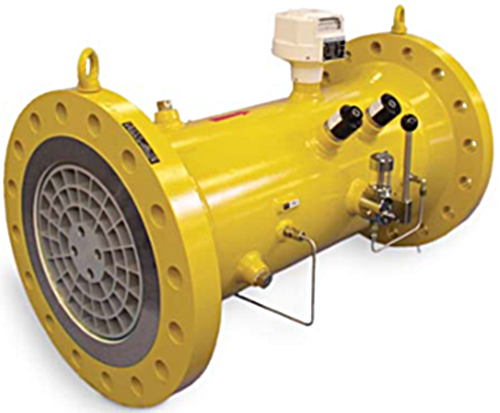

4. Ultrasonic Gas Flow Meter (USM) - Q.sonic Plus/Max

The Q.Sonic Plus ultrasonic gas flow meter features a patented six-path ultrasonic wave reflection design by Elster-Instromet, enhanced with expanded functionality for end-users. It offers improved processing power for lower uncertainty in measurements.

- Configurable path design for swirl and asymmetric flows, facilitating diagnostic and source identification unmatched by competitors.

- Equipped with internal pressure and temperature measurements, enabling flow profile analysis and geometry calibration.

- Real-Time Operating System (RTOS) managed data encryption, ensuring one of the most secure real-time operating platforms globally.

- Electronics housed in a fire-resistant enclosure with a dedicated wiring compartment.

- Modular hardware design with an empty slot for future expansion.

❖ Specifications:

- Gas Types: LPG, CNG, Argon, etc.

- Sizes: DN25 (1"), DN50 (2"), etc.

- Accuracy: ~0.1 - 1% (commercial use), ~1 - 2% (non-commercial use)

- Operating Pressure: 0 ~ 100 bar (Class 150 to Class 600)

5. Considerations When Choosing Gas Flow Meters

The ion of gas flow meters depends on various factors such as:

- Installation location (indoors, outdoors, harsh conditions)

- Application in which industry/service?

- Operating pressure on the pipeline where the meter is installed

- Maximum gas usage capacity (m3/h, Sm3/h, Nm3/h)

- Required accuracy or permissible error

Other factors include quality, durability, safety level, and supportive features. Each gas flow meter installation should consider straight flow pipe distances before and after each meter.

For detailed information and optimal gas flow meter advice, please contact us via hotline at +84 787179275 – +84 941234456.