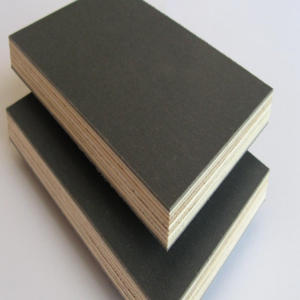

Film Faced Plywood

♣♣♣ Quality and Durability are keys to a Safe and Sound construction project.

♣♣♣ That`s why Anh Duong Xanh Production Construction Company is pleased to offer Film Faced Plywood, a sturdy and reliable option for builders and contractors alike. Made with a durable film coating that provides an extra layer of protection against wear and tear, our Film Faced Plywood is perfect for everything from concrete formwork to flooring. Plus, with its bold appearance and long-lasting performance, its a cost-effective choice for any project. So lets have a look into its details. Shall we ?

♣ INFORMATION

1. Structure

- Film is known as a Phenolic laminate with outstanding waterproof and scratch-reducing properties.

- The layers of boards are attached with WBP water-resistant glue under high pressure, combined with the film coating on the surface.

- Film Faced Plywood has a detailed structure consisting of 3 main components:

.jpg)

2. Characteristics

- Film Coated Plywood is the most preferred option in the construction projects due to these advantageous features:

⊛ Low distortion, keep stable shape after long time use: the wood core of film-coated plywood is composed of many thin layers of laminated wood stacked in combination with specialized glue to increase the cohesion of the board.

⊛ Water and heat resistance even in harsh environments: the products are adhered with water-resistant BWP, then tested for a 72-hour boiling process without delamination. In addition, the moisture content of the boards is always kept at an ideal level of 12%, so the formwork board is able to withstand water and heat well without being moldy even in harsh environments.

⊛ Easy to build: compatible with all kinds of machines, have good screw adhesion to make construction and installation easier. With a lighter weight than other materials such as steel or natural wood, the transportation of formwork is also light and saves construction time.

⊛ Reasonable cost, high reusability: When assembling the formwork, the film-coated planks form a sealed surface, fixing the concrete inside, avoiding the loss of materials due to the flowing cement. Thanks to the smooth film, this concrete surface after removing the formwork is flawless, so that it can be painted directly and be reused up to 20 times. Thus, contractors and investors can be completely assured of the quality of the work and still optimize the cost problem.

⊛ Safe with health & Environmental friendliness: Our rigorous manufacturing process is based on CARB P2 and TSCA Title VI standards. These are the standards set out to control the amount of Formaldehyde emissions that affect human health as well as the environment. The glues being used for the production of film-coated formwork plywood all meet E0 standards with emission concentrations < 0.07ppm, completely harmless to human health. In addition, the source of raw wood is exploited from licensed plantations, limiting the use of natural wood, which affects the ecosystem.

3. Specifications

.jpg)

⊛ Core Wood: Melaleuca, Eucalyptus, Fat,…

⊛ Surface: Film Coated

⊛ Requirement: Raw materials are 100% heat-dried

⊛ Outcome specification: 1220mm x 2440mm

⊛ Specification tolerance: +/- 2mm

⊛ Thickness tolerance: +/- 0.5mm

⊛ Plank moisture: 12 +/- 2%

⊛ Thickness: 12mm - 18mm

♣ USABILITY

1. Warranty

- There is a must of proper storage and use of film plywood to increase their durability. To help customers save their expenses, here are several noticeable instructions from ADX Plywood :

⊛ Before the use

⊛ While using

⊛ After using

2. Usage

⊛ Construction Industry

Film-coated formwork plywood is an industrial wood with high mechanical strength, light weight, can resist mold, termites and screws extremely well, trusted in the construction industry. Along with that, this type of board can be reused many times, helping the contractor to save the maximum cost of materials and labor. Therefore, this type of industrial plywood is used as a mold for pouring beams, concrete, etc.

⊛ Exterior Furniture

In addition to the construction field, film-coated plywood is also popular for application in exterior works. Thanks to its outstanding advantages, products from this material can be used for interiors in places with high humidity and good bearing capacity such as cabinets, tables and chairs, garage floor, warehouse, etc.

⊛ Navigation Industry

Not all types of industrial wood can be used in the marine industry like film-coated plywood. With water resistance, stable structure without peeling or delamination through the 72-hour boiling test, Film Faced Plywood is trusted in the marine field such as shipbuilding, container decking, etc.

At ADX Plywood, we know that building materials are the backbone of any construction project. Thats why we stand behind our Film Faced Plywood - a tough and reliable option that wont let you down. Whether youre building a new home, a commercial building, or a bridge, our Film Faced Plywood is the perfect choice for your project.

♣♣♣ Contact us today to learn more about how we can help you achieve your construction goals. ♣♣♣

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)