HERTZ PISTON AIR COMPRESSOR

What is the secret to choosing a reputable and quality Piston Hertz Air Compressor?

➥ Choose a well-known brand in the market.

➥ Superior product quality and enthusiastic staff.

➥ Reasonable product price.

➥ Positive customer feedback and reviews.

Phu Tin Company is a leading company in Vietnam and is the authorized distributor of air compressors from the US and Europe, Germany, Taiwan, etc. Our choice of Hertz Piston Air Compressor is a best choice for you!

Series of Hertz Piston Air Compressors

➽ PET MASTER

➽ HPC Pet/Plus Series / HPC Booster Series and GP Series

➽ WAVE Series

➽ HPC Series Starting Air

➽ Single and Double Stage Series

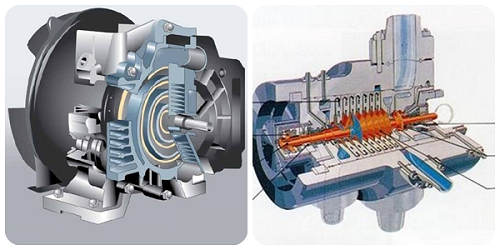

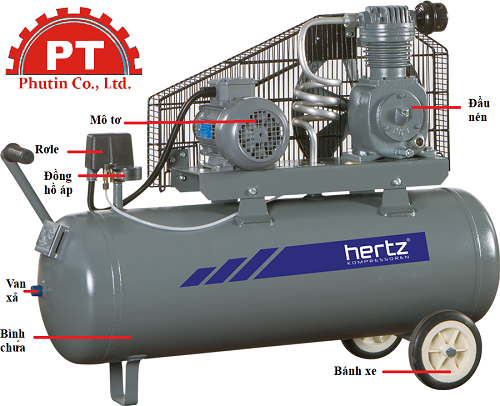

Structure of Piston Hertz Air Compressor

● Piston top: As a place to receive gas pressure, it usually has 3 types of flat top, convex top and concave top.

● Piston body: It is the rest that guides the piston to move in the cylinder and connects to the connecting rod to transmit force.

● Drain valve: Removes water vapor in the compressed air, ensuring the quality of the air is completely dry before it is put into the equipment and machinery.

● Compressed air tank: Used to store compressed air and regulate pressure at the outlet.

● Pneumatic head: Composed of compression piston, inlet air filter, air outlet pipe, etc

● Filter: Prevent all dust from the outside environment from entering the air compressor during operation.

● Pressure regulating relay: Automatically shuts off - opens the piston air compressor when it has reached the preset pressure.

● Safety valve: To keep the gas pressure at a constant level, preventing sudden rise. Minimizing the cases of fire and explosion caused by the air compressor.

● One-way valve: With the function of stabilizing the outlet pressure, the gas will go out in a certain direction.

Working principles

➠ Hertz piston compressors include 2 lines: level 1 piston compressors and level 2 piston compressors. Both of these lines are based on the reciprocating movement of the piston left, right or up and down. As the piston moves, the pressure and volume inside the gas chamber will change and the air will be compressed in the air chamber.

➠ When the pressure in the compression chamber is greater than the exhaust valve pressure, the exhaust valve will be opened and the compressed air will be opened and then pushed out of the pipeline system. Then the steam compression process will be started again.

* Differences in operating principle of level 1 piston compressors and level 2 piston compressors

Stage 1 piston compressors:

➠ Air will be drawn directly from the internal environment through the air filter and to the piston.

➠ At this time, the air will be compressed and pushed out into the compressed air tank, and the compressed air will only be compressed once.

Stage 2 piston air compressor:

➠ The air will go from the outside environment to the inside of the compressor, pass through the filter then to the piston.

➠ Next, the air will be compressed at high pressure and temperature and then through the cooler.

➠ At this time, the cooler is responsible for cooling the compressed air and then passing it to the 3rd piston.

➠ Air is compressed at a higher pressure, then pushed through the compressed air tank system.

Applications of Piston Hertz Air Compressors

❉ Motorbike and automobile repair and maintenance industry

❉ Application in unclogging drains

❉ Medical and food applications

❉ Supply for divers, for workers working in mines.

❉Support many other activities such as mining, manufacturing, assembling electronic components, and construction.

Advantages of Hertz Piston Air Compressors

✔ Compact design, light weight, equipped with convenient moving wheels.

✔ Does not take up storage space, convenient to disassemble in detail assemblies, helping to save maximum installation time and effort for equipment operators.

✔ Working efficiency is quite good, meeting the work requirements of many different industries

✔ Affordable price, the maintenance and repair is quite easy, does not cost much effort and cost of the user.

If you want to get any further information, please don’t hesitate to contact!