JIGS, FIXTURES & CUTTING TOOLS

In mechanical manufacturing, to achieve high precision, high productivity, and optimized costs when machining mechanical parts, the use of jigs, fixtures, and cutting tools is indispensable.

- Jigs and fixtures are devices used to locate, clamp, and secure workpieces, ensuring they remain in the correct position throughout the machining process.

- Cutting tools are tools that directly cut materials, shaping and finishing parts according to technical requirements.

These two groups of tools work closely together to improve accuracy, reduce errors, and enhance production efficiency in modern machine shops.

1. Jigs & Fixtures

🔹 Definition

Jigs and fixtures are auxiliary devices used in machining to locate, clamp, and support workpieces. Some jigs also guide cutting tools during machining operations.

🔹 Classification of Jigs & Fixtures

By application:

- Milling fixtures

- Turning fixtures

- Drilling & boring fixtures

- Grinding fixtures

- Assembly fixtures

By level of specialization:

- Universal fixtures

- Dedicated (special-purpose) fixtures

- Adjustable fixtures

By clamping mechanism:

- Manual clamping fixtures

- Pneumatic fixtures

- Hydraulic fixtures

- Magnetic fixtures

🔹 Functions & Advantages of Jigs & Fixtures

✔ Absolute workpiece positioning accuracy

✔ Secure clamping capable of withstanding cutting forces and vibration

✔ Increased productivity and reduced setup time

✔ Reduced errors caused by manual operations

✔ Improved workplace safety

✔ Accurate tool guidance (for drilling and boring jigs)

2. Cutting Tools

🔹 Definition

Cutting tools are tools that directly remove material from workpieces, shaping and finishing machine parts according to technical drawings.

🔹 Classification of Cutting Tools

By machining method:

- Turning tools

- Milling cutters

- Drill bits

- Boring & reaming tools

- Grinding wheels

By tool material:

- High-Speed Steel (HSS)

- Carbide

- Ceramic

- Diamond

- CBN

By structure:

- Solid tools

- Brazed tools

- Indexable tools

🔹 Functions & Advantages of Cutting Tools

✔ Precise and stable part forming

✔ High-quality surface finish

✔ Machining of a wide range of materials, from soft to hard

✔ Higher cutting speeds and increased productivity

✔ Long tool life, reducing production costs

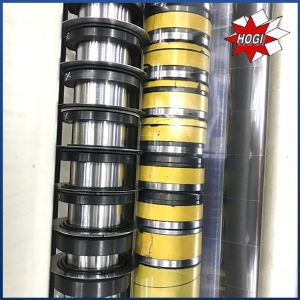

3. Hogi Vietnam - A Trusted Designer & Manufacturer of Jigs, Fixtures & Cutting Tools

HOGI Viet Nam Technology Company Limited specializes in the design and manufacturing of high-precision jigs, fixtures, cutting tools, and technical JIGs, serving many domestic and international enterprises, particularly from Japan and South Korea.

Jigs & Cutting Tool Services at Hogi Vietnam

✡ Milling, turning, drilling, grinding, and assembly fixtures

✡ Dedicated fixtures and automation fixtures

✡ Straight cutters, circular cutters, and form cutters

✡ Inspection jigs, assembly jigs, and welding jigs

✡ Manufacturing based on drawings or actual application requirements

Outstanding Manufacturing Capabilities

✅ 30 modern CNC milling machines with automatic tool changers

✅ Factory expanded to 2,000 m²

✅ High-precision, stable, and consistent machining

✅ Capable of handling high-technical and large-volume orders

Commitments from Hogi Vietnam

✔ Fast delivery - on schedule

✔ High precision - consistent quality

✔ Reasonable, competitive pricing

✔ Dedicated after-sales service

Contact HOGI Viet Nam Technology Company Limited today for consultation on suitable jigs and cutting tool solutions to help your business optimize production processes, increase productivity, and reduce costs.

.jpg)