Instron high capacity systems are servohydraulic fatigue testing systems that perform high force static and dynamic tests on specimens up to 5000 kN. These machines use the same software, electronics, and interfaces as all of our general hydraulic fatigue machines, which ensures continuity and consistent experience across machines in your laboratory. Instron will also provide support from dedicated project engineers to design and manufacture high capacity machines and accessories to meet your needs.

COMMON FEATURES

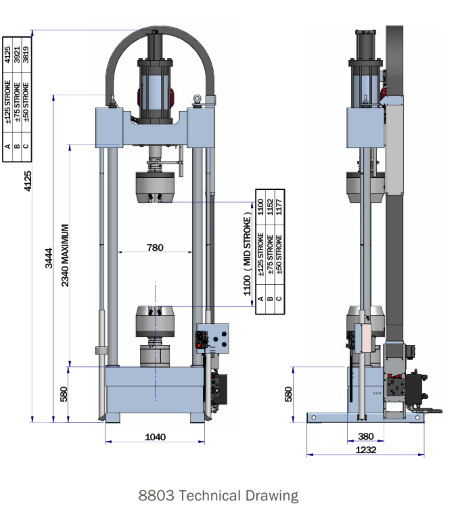

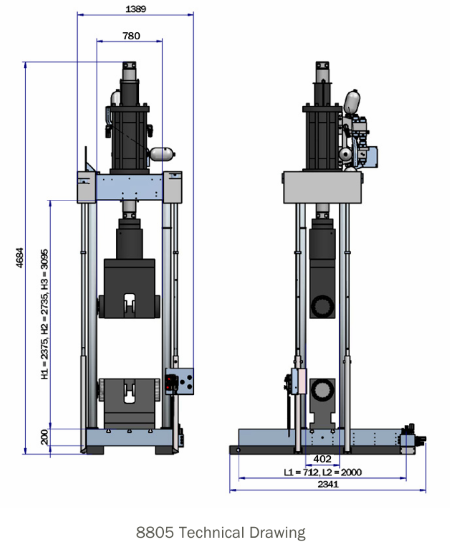

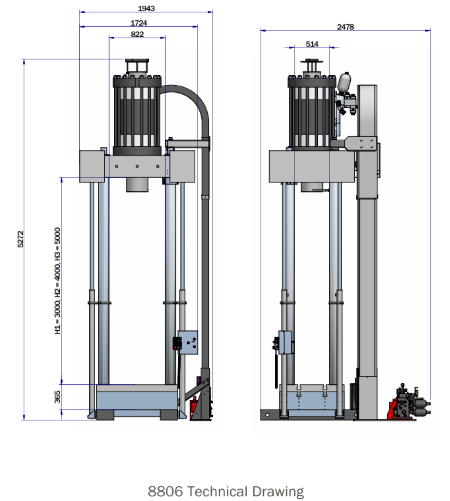

High-stiffness, precision aligned load frame with induction hardened chrome plated columns and actuator in upper crosshead

Designed for both dynamic and static testing on a variety of materials and components

Choice of actuator stroke, hydraulic configuration, and dynamic performance to suit the application

T-Slot base and other test space configurations available

Adjustable upper crosshead with hydraulic lifts and lock fitted as standard with optional Telescopic lift cylinders on some models • Patented Dynacell™ Advanced dynamic force rated load cell up to 2500 kN

Pressure transducers for load measurement available as an alternative for larger capacities

Compatible with a range of high capacity grips, fixtures, environmental chambers, video extensometers, protective enclosures, and other accessories

OUR RANGE

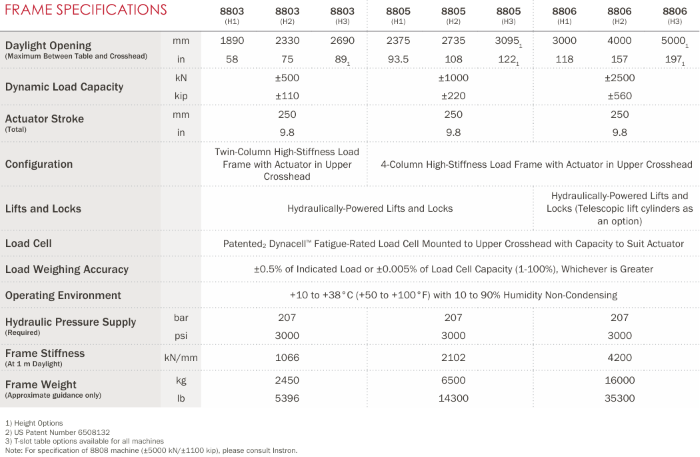

2-column 8803 system is rated at ±500 kN (±110 kip)

4-column 8805 system is rated at ±1000 kN (±220 kip)

4-column 8806 system is rated at ±2500 kN (±560 kip)

4-column 8808 system is rated at ±5000 kN (±1100 kip)

CONTROLLER AND SOFTWARE

The Instron high capacity machines are supplied with a digital 8800MT controller that provides consistent user experience across all Instron fatigue systems. The 8800MT controller features automatic loop tuning, amplitude control specimen protect, 19-bit resolution across the full range of transducers, and adaptive control technology. It also allows access to WaveMatrix™ 2 Dynamic Testing Software, Bluehill® Software for static tests, and other application specific software, such as the Low Cycle Fatigue or Fracture Mechanics suite.

HIGH CAPACITY FATIGUE TESTING HIGH CAPACITY FATIGUE TESTING

Materials can fail prematurely if they are exposed cyclic loading for a certain period of time, even if the operating stress profile is lower than the yield stress, this is known as fatigue. It is one of the main focuses in material testing in terms of determining a product’s life cycle, and it provides insight into how the materials will fail, allowing engineers to take this information into account when designing a product.

Fatigue rated testing machines are used to perform fatigue tests. They can characterize the fatigue life of different materials, verify computational life cycle models of materials and ensure components behave accordingly under cyclic loading. The dynamic capacity required to test high-performance metals and engineering alloys is significantly higher than that of compliant polymers, bringing the need for high capacity fatigue systems that have enough dynamic load capacity to test a wide range of old and newly developed metals, alloys and components.

HIGH CAPACITY FATIGUE APPLICATIONS AND RESEARCH AREAS INCLUDE:

Characterization of high-performance materials under cyclic loading

Determining the cumulative damage of components

Weight reduction of components

Microstructure refinement of spring steel

Thermally induced strain and stress profiles of materials

WHY CHOOSE INSTRON?

For testing at forces of 500 kN and above, Instron provides a range of servohydraulic machines up to 5000 kN for testing of a wide range of high-performance materials. These machines use the same software, electronics, and interfaces as all of our hydraulic fatigue machines, which ensures continuity and consistent experience across machines in your laboratory. The challenges involved with purchasing and installing a machine of this size are very different from those of a more common, lower load capacity fatigue machine. We have an expert team of experienced project engineers who will support you from the initial configuration process through to the final installation and acceptance testing. If you are interested in high-frequency performance, Instron also offers high performance, seal-less actuators for high capacity testing.

BENEFITS

Hydraulic actuators with hydrostatic bearings for axial alignment and sideload protection operating at 210 bar and a seal-less 280 bar actuators for high performance and high lateral stiffness, depending on your testing requirement

Hydraulic crosshead lifts and clamps, allowing easy and accurate adjustment of daylight depending on the size of fixtures and specimen

Versatile test space with a t-slot table for component tests

Same controls and software as lower capacity general fatigue machines, giving a seamless transition between different systems

Actuator in upper crosshead with IGUS chain hose management to prevent overhanging cables around the machine

NO SPECIAL TRAINING NEEDED

While the high capacity machines are significantly larger than most hydraulic test frames, which prompts a different specimen handling procedure with the larger sized specimens and accessories, the machines are compatible with the same electronics, software and user interfaces as any of our hydraulic fatigue machines. There will be a seamless transition between smaller capacity machines to these high capacity machines with our user-friendly software packages.

Easy access to frame and grip controls from the workstation

WaveMatrix™3 Software for block loading cyclic fatigue test

Bluehill® Universal for static tensile and compression testing

INSTRON DEDICATED PROJECT SUPPORT

Instron offers a range of high capacity frames to meet the needs of your test and a dedicated project engineer to assist you along the purchasing process and system handover. The frame itself can be configured with a T-Slot table to suit larger component testing or with a load string to suit your test specimens. All of our high capacity frames include an IGUS chain hose management system or other dedicated hose management systems for larger machines to ensure ease of crosshead adjustment while maintaining a test space free of overhanging hoses.

HIGH CAPACITY LOAD STRINGS FOR YOUR APPLICATION

As well as providing comprehensive support throughout the specification, design, and installation of your high capacity machine, Instron will be able to provide a range of high capacity accessories to support your testing application.

High Capacity Compression Platens

1 MN R-Curve 16’’ Panel Grips

2.5 MN Side-Action Hydraulic Grips

Contact us here for prompt and dedicated support!

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)