WELDING SERVICE - PROFESSIONAL METAL WELDING & FABRICATION AT HK LASER VINA

Welding & fabrication is the most critical stage that determines mechanical strength, structural stability, and product aesthetics in sheet metal manufacturing. At HK LASER VINA, we operate with a team of highly skilled welding technicians, combined with modern MIG - TIG - Fiber Laser welding systems, delivering strong, clean welds with minimal deformation, meeting export-grade quality standards.

Why is welding a core factor in metal fabrication?

- It determines the overall durability of frames, enclosures, mechanical structures, and metal components.

- Weld quality directly affects product aesthetics and long-term performance.

- A well-executed weld reduces post-processing requirements → saving time, cost, and improving production efficiency.

→ For this reason, HK LASER VINA invests heavily in welding technology and workforce training to produce perfectly finished products from structure to surface.

Why use Fiber Laser Welder?

◆ Continuous laser welding creates stable, smooth weld seams

◆ Stronger welding strength

◆ Minimal deformation and small weld beads

◆ Little to no polishing required → saving labor and time

◆ Compact integrated machine requires minimal floor space

◆ Fiber cable enables long-distance operational welding

◆ Bottom caster wheels allow easy movement and positioning

Welding capability at HK LASER VINA

1. Experienced welding professionals: Our engineers and welders are well-trained, knowledgeable in materials and welding techniques, ensuring products with:

✔ Strong structural integrity

✔ Clean welds with minimal burrs

✔ Meeting technical standards before final assembly

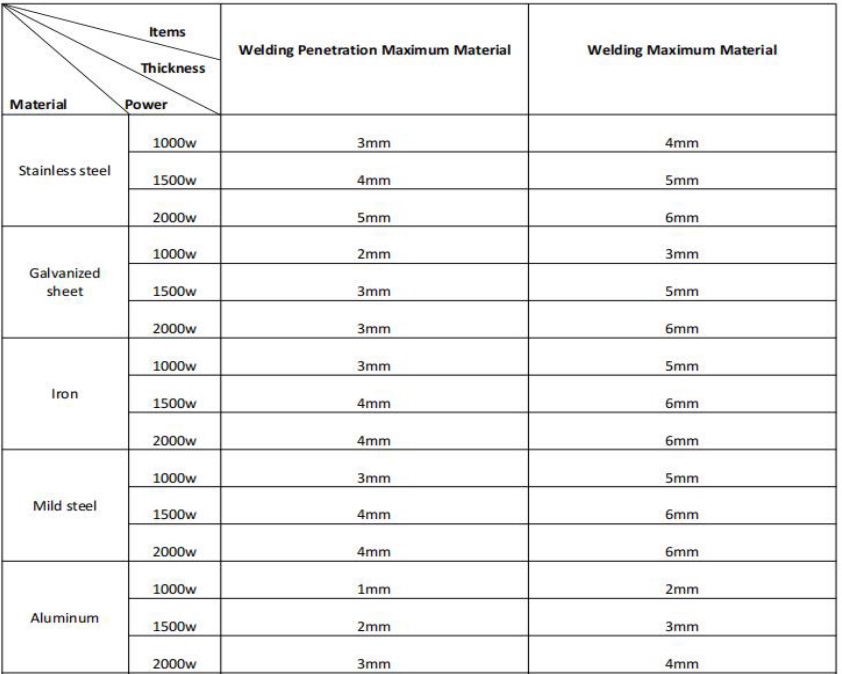

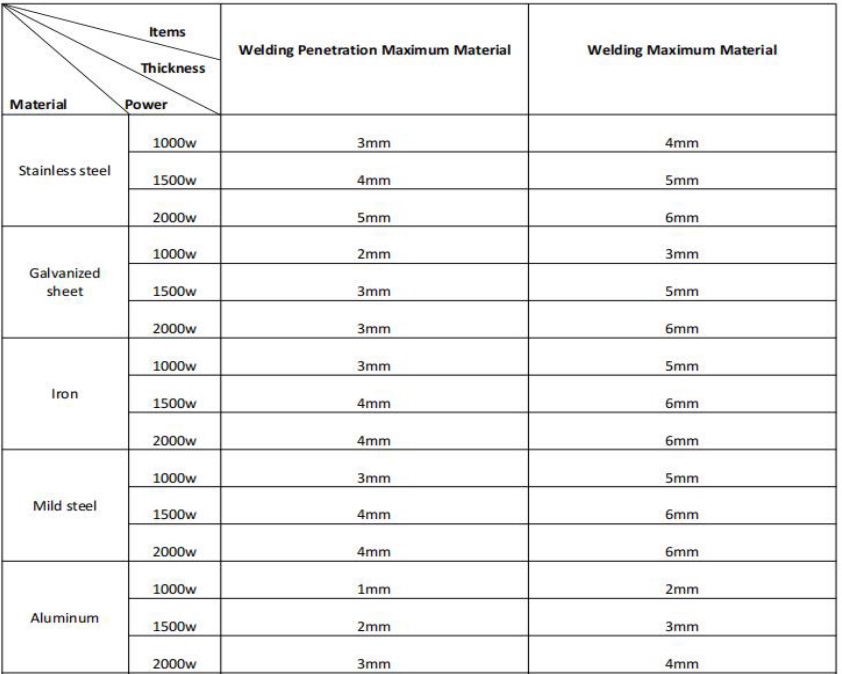

2. Multi-material welding capacity: HK LASER VINA handles small prototype runs and high-volume production orders, including: Stainless steel, Mild steel, Aluminum

3. Welding methods we provide:

- MIG welding: High speed, suitable for mass production

- TIG welding: Fine, aesthetic weld seams

- Fiber laser welding: Superior precision - low deformation - almost no polishing required

Professional welding equipment

|

|

|

TAEWON WELDERS 350CM CO2/MAC

Rated Output Current - 350A

Input Voltage - 220V/380V

Rated Frequency - 50/60HZ

Rated Input - 16 KVA

Output Power Range -50~350A

Output Voltage Range-16~36V

|

|

Autowell WELDERS 350AD

Output Current - 350A

Input Voltage - 220V/380V

Rated Frequency - 50/60HZ

Rated Input 7.5 KVA

No Load Voltage - 72V

|

Comprehensive metal fabrication solutions

Welding & fabrication is a key link in HK LASER VINA’s closed-loop production system, combined seamlessly with our core services:

- CNC Fiber Laser Cutting

- CNC Bending & Forming

- Assembly & Installation

We supply components, metal structures, panels, enclosures, and complete assembled units for industries including Energy, Automotive & Semiconductor, Industrial Kitchen Equipment, Agricultural Machinery, and more.

👉 Contact us today for professional consultation on MIG, TIG, and Fiber Laser welding solutions, as well as detailed quotation for high-volume production orders.