CNC TURNING SERVICE

CNC turning is widely used (accounting for 25‑35%) in the material cutting and machining process. With nearly 10 years of experience manufacturing for Japanese, Korean, American clients etc., Hoang Son Precision is confident in supplying customers with precision mechanical products of the highest quality and the best prices on the market.

What is CNC turning?

Turning is a machining method carried out by the rotating movement of the workpiece combined with feed movements (longitudinal or transverse).

Computer Numerical Control, or CNC, refers to machines that are controlled automatically with computer assistance components are programmed to operate according to pre‑set instructions. CNC cutting machines can work in 2D or sculpt in 3D.

CNC turning is a machining method using machinery and computer control technology to ensure high precision and high working speed.

CNC turning process at Hoang Son Precision

Turning demands high finesse and precision. Therefore, at Hoang Son Precision we always focus on building a professional process to ensure a 98% accuracy rate right from the first prototype.

➦ CNC turning process at Hoang Son Precision:

- Receive and review customer requirements check 2D drawings and 3D files provided (if any), to ensure all dimensions are correct.

- Accept customers PO and prepare an overview of the order.

- Create quotation.

- Produce drawings + production order (work order) + traveler.

- Engineering checks the drawing (re‑verify measurements, symbols).

- Issue billet release form + job assignment form + billets specifications.

- Machine setup handover form + machine run handover + standard inspection form.

- FAI (first article inspection).

- QC engineers inspect the sample product to ensure technical specifications are met: tool holder length, allowance margin of the part, etc. send inspection standard form along with the product.

- Proceed with full CNC turning as programmed and deliver the product to customer.

CNC turning capacity

Over many years of development, Hoang Son Precision has risen to become one of the leading mechanical manufacturing and machining service companies in the Northern region. With an automation equipment system, Hoang Son Precision has been chosen by many large domestic and foreign partners.

➦ Human resources

At Hoang Son Precision, the human factor is always emphasized and developed. We have a team of 16 technical experts with high professional qualifications and 10 years of experience in the field, ed from major universities in the country, and who have had opportunities to exchange and learn advanced knowledge abroad. The machine operators, QA/QC team, and sales staff are all fully equipped with knowledge of precision mechanics.

Work ethic at Hoang Son Precision is based on responsiveness, flexibility, while still pursuing the careful, meticulous precision required in precision mechanics, ensuring productivity and quality in workmanship.

➦ Machinery & equipment

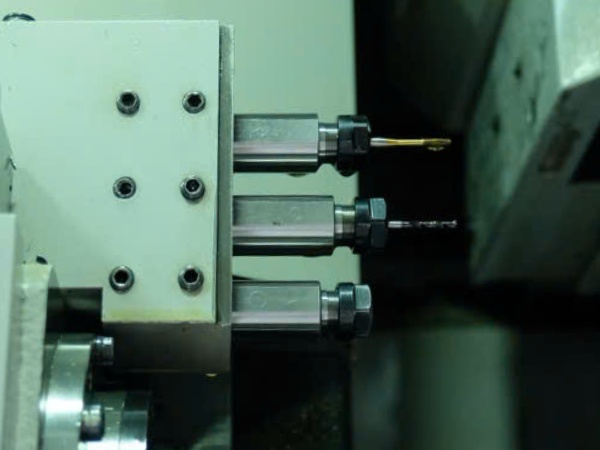

The factory is equipped with modern CNC turning machines and measuring equipment, high capacity, imported directly from Japan ensuring the supply of turned round parts and finished mechanical products with exquisite, sharp and high precision details, meeting diverse customer requirements.

➦ Machining experience

After nearly 10 years of collaboration with major partners from Korea, Japan, the USA, we have gradually established relationships to provide mechanical machining services, especially CNC turning.

Our strength includes nearly 12 engineers specializing in designing and programming CNC turning experienced in risk control and resolving arising issues, ensuring highest precision. All machinery is imported directly from Japan. The production and packaging process is strictly quality‑controlled using measuring machines. Sales staff have solid mechanical engineering backgrounds, follow the machining production process closely, accept drawing files online 24/24 (including hand‑drawn drawings).

➦ Materials

Hoang Son Precision commits to using materials with import certificates and material certificates (CO‑CQ). We are able to supply the following available materials: aluminum, stainless steel, steel, copper, etc.

Strengths of CNC turning service at Hoang Son Precision

✔️ Modern CNC turning systems imported directly from Japan help shorten processing time.

✔️ Turning machines have high speed and large cutting force precision up to ± 0.005 mm to meet even strict requirements for complex parts.

✔️ All measuring tools are 100% calibrated, ensuring maximum accuracy for products.

✔️ Team of experienced engineers in CNC turning programming helps us maintain a large CNC turning database, minimizing risk and handling emerging issues well. This helps process your CNC turning orders quickly and with high efficiency.

✔️ The measuring room machinery is fully equipped according to international standards, ensuring high accuracy finished products meet tolerances, surface roughness, polish, etc. as required by drawings.

✔️ Absolute confidentiality of customer information.

Contact Hoang Son Precision for CNC turning

Hoang Son Precision is confident in meeting diverse customer requirements, bringing satisfaction through high‑quality products.

For specific consultation on CNC turning services, please contact hotline +84 823582626 / +84 823192626 or email: info@hoangsoncnc.com.