Automated Sheet Metal Punching Services

Introduction

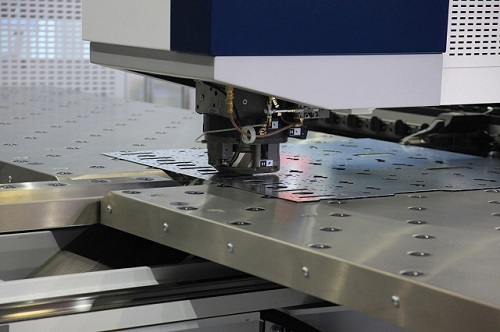

When you witness the fully automated sheet metal cutting and punching systems in action at SIBA Group, it’s easy to understand our unwavering commitment to leading the industry in high-volume precision metal manufacturing. Our advanced technology and state-of-the-art large-format punching centers redefine metal fabrication by dramatically increasing productivity in response to growing production demands.

SIBA Group operates multiple punching systems, supported by automated material handling towers. This scalable setup is designed to meet the long-term development goals of your product. From material handling to tool automation, we set the benchmark for efficiency, reliability, and flexibility.

Unmatched Precision with Tight Tolerances

At SIBA Group, we are known for producing precision metal components through innovative, cost-effective manufacturing solutions. We work closely with OEM clients across various industries, offering end-to-end services — from collaborative design support to final delivery. Our facilities combine cutting-edge tools, technologies, and talent to deliver world-class fabricated metal products, including high-quality welded assemblies.

Cost-Effective Manufacturing

Our automated sheet metal punching technology delivers significant cost savings from prototyping to mass production. We minimize material usage, reduce machining time, and streamline production — all while meeting or exceeding product performance standards. By designing parts with self-fixturing features such as notches, interlocks, hinges, and specialized contours, we help OEM clients achieve cost reductions of over 20%, cycle time reductions of 20–60%, and a 5–15% decrease in material usage. BOM (Bill of Materials) simplification is also achieved by eliminating unnecessary fasteners.

Maximized Productivity

SIBA Group is committed to maximizing productivity across every stage of manufacturing. We leverage the latest automation technologies to ensure flexibility, high precision, and fast throughput. Our investments in leading global equipment brands are matched by continuous training for our team on the latest manufacturing processes. Our design and engineering experts review each product to determine the most efficient production approach and explore design improvements to further enhance functionality and manufacturability.

Our Strengths

As a trusted name in precision sheet metal fabrication, SIBA Group delivers innovative, efficient, and cost-effective manufacturing solutions. We provide a full-service offering to OEM partners — from co-engineering support to the production of finished, high-quality fabricated components.

Our business network spans across all provinces in Vietnam and international markets including Germany, Italy, Switzerland, Japan, South Korea, Thailand, China, Singapore, Myanmar, Guinea-Bissau, and Tanzania.

To meet the growing demands of the market and increasingly stringent quality standards, SIBA Group continuously innovates and invests in cutting-edge machinery sourced from top European brands — all dedicated to the field of mechanical manufacturing.

Guided by the motto “Constant Innovation, All for Customer Benefit,” SIBA Group is committed to being a reliable partner and provider of high-quality products at competitive prices. We also foster a supportive and rewarding work environment to encourage our team to create new value for customers, partners, and society as a whole.

Contact SIBA Group today to learn more about our sheet metal punching services and how we can support your manufacturing goals with precision, speed, and cost-efficiency.