ASTM A193 BOLTS

What is ASTM A193?

ASTM A193 is a standard specification covering the material, mechanical properties, and dimensions of bolts and threaded rods. These bolts are widely used in industries such as oil and gas, chemical processing, and high-temperature, high-pressure environments. ASTM A193 bolts and threaded rods are designed for securing and connecting pipelines, valves, flanges, pressure vessels, and other critical components.

Quang Thai Bolts directly manufactures and distributes ASTM A193 bolts, studs, and threaded rods, complete with certification and factory documentation. We are committed to providing high-quality ASTM A193 bolts at the most competitive prices on the market.

Key Features of ASTM A193 Bolts

Material Composition

ASTM A193 bolts are classified based on strength grades, including:

• B7, B7M: Alloy steel with chromium and molybdenum, heat-treated and tempered.

• B16: Alloy steel with chromium, molybdenum, and vanadium, heat-treated and tempered.

• B8: 304 stainless steel, carbide solution treated.

• B8 Class 2: 304 stainless steel, carbide solution treated with additional hardening.

• B8M: 316 stainless steel, carbide solution treated.

• B8M Class 2: 316 stainless steel, carbide solution treated with additional hardening.

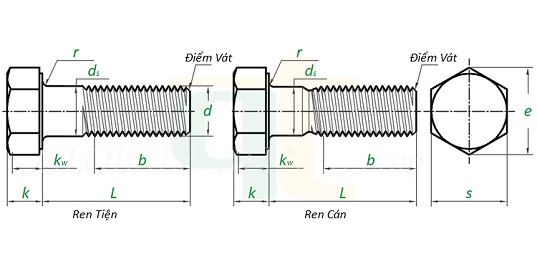

Thread Types

ASTM A193 bolts come in various thread types based on U.S. standards:

• UNC (Unified National Coarse): The most commonly used coarse thread type in the U.S., ideal for applications requiring quick assembly and disassembly in low-strength materials like low-carbon steel.

• UNF (Unified National Fine): A fine-threaded variant used for high-strength connections or in applications with thin walls and short engagement lengths.

• 8UN: A special UNC variant where the number of threads per inch remains constant at 8 TPI (threads per inch) across different diameters.

Dimensional Standards

Quang Thai Bolts manufactures ASTM A193 bolts according to ASME B18.2.1 – 2012 standards.

Surface Treatments

Due to their frequent use in harsh environments such as the oil and gas industry and chemical processing, ASTM A193 bolts often require protective coatings, including:

• PTFE Coating

• Hot-Dip Galvanization

• Black Oxide Coating

• Electro-Galvanization

• Geomet Coating

• Dacromet Coating

Applications of ASTM A193 Bolts

• Widely used in the aerospace, oil and gas, petrochemical, and chemical industries.

• ASTM A193 B7 and B8 bolts are commonly used for flange connections in oil and gas pipelines, water treatment facilities, and process industries.

• ASTM A193 B16 bolts are ideal for high-temperature environments and used in assembling stainless steel valve systems and pipelines.

• ASTM A193 bolts are extensively used in the construction and installation of boilers, pressure vessels, and chemical tanks handling high-temperature liquids.

Pricing of ASTM A193 Bolts

The cost of ASTM A193 bolts and threaded rods depends on several factors:

• Type: Each ASTM A193 standard fastener has a different price based on its shape and manufacturing process.

• Strength Grade/Material: Higher-strength grades generally cost more. For example, ASTM A193 B8M is more expensive than B8, which in turn is costlier than B7M and B7.

• Size: Larger diameters and longer bolts are more expensive. For example, ASTM A193 M42 bolts cost more than M39, and M20x120 bolts cost more than M20x100.

• Surface Treatment: Different coatings have varying costs based on their characteristics and benefits. For instance, PTFE-coated bolts are more expensive than hot-dip galvanized ones, which in turn are costlier than electro-galvanized bolts.

Why Choose ASTM A193 Bolts from Quang Thai?

Quang Thai Bolts takes pride in being a leading manufacturer and distributor of ASTM A193 bolts and threaded rods in Southern Vietnam. Our company is recognized as one of the best suppliers of high-quality fastening solutions at competitive prices. We prioritize product quality to ensure reliability and customer satisfaction.

For the best ASTM A193 bolts, contact us at +84 933 220 468. Quang Thai is honored to serve you!