Trong Tien is one of the leading manufacturers of metal roll forming machines in Vietnam, established in 2006. In this article, we are pleased to give customers the technical specifications of the Cable/Ladder and Trunking Auto Interchangeable Roll forming Machine.

|

ITEMS

|

SPECIFICATIONS

|

|

Drive motor

|

15 kw/ 415V/ 3phase/ 50Hz

|

|

Size change geared motor

|

2x0.75 kw/ 415V/ 3phase/ 50Hz

|

|

Weight of machine

|

Approx. 8.5 tons

|

|

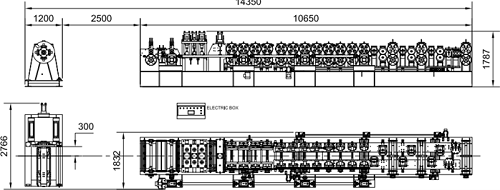

Machine dimension (L x W x H)

|

Approx. 10.5m x 1.5m x 1.5m

|

|

Line speed

|

10-15 MPM

|

|

The chassis of machine

|

The chassis of the machine is made from medium-duty welded steel I 400 steel and pedestal machined steel with a thickness 22mm upright welded to chassis.

|

|

Rollers

|

Made of S45C base material solid form CNC precision machined, through hardened with hard chrome finish 50HRC

|

|

Dia. of shaft

|

70mm

|

|

Nos. of rollers station

|

20 stations .

|

|

Straightening device

|

5 rollers for straightening material before forming

|

|

Guillotine

|

Stop to cut stationary hydraulic: Pre-cut dies, made of SKD 11 base material solid form CNC wire cutting machined, through hardened 55HRC

|

|

Hole punching

|

Stop to punching hole stationary hydraulic: Punching tools made of SKD 11 material solid form CNC wire cutting machine, through hardened 55HRC

|

|

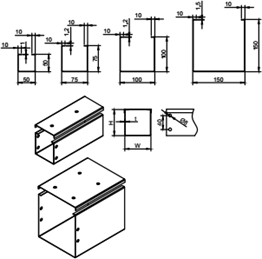

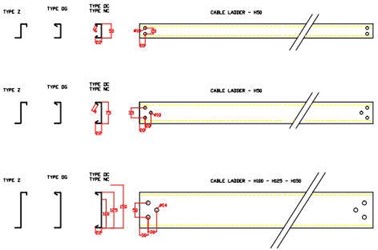

Trunking and covers sizes

ging method

|

Auto changing sizes of trunkings and covers on Siemens touch panels.

|

|

Guarding

|

2 sides guarding with lockout

|

|

Control system of machine

|

Fully automatic roll forming. Stop to cut and hole-punching digital

Length and multi orders by Siemens PLC and Touch panel

|

|

Accuracy

|

+ 1.0mm

|

|

Height of center machine

|

Approx. 700mm

|

|

Cooling system

|

The hydraulic system is equipped with an air cooling system that permits the machine to operate continuously from 16 to 20 hours per day.

|

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)