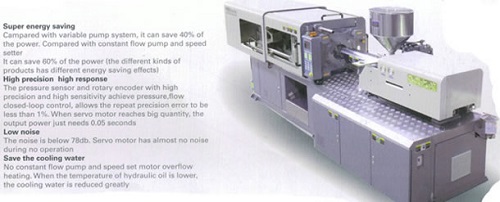

HXM SERIES SERVO MOTOR INJECTION MOLDING MACHINE

Characteristics

HXM series servo motor injection molding machine utilizes the high-performance servo dynamic control system and oil pump as power source, having such characteristics as follow: high response, saving energy, low noise, high-control precision, etc. What’s more, it breaks through the tradition with the perfect combination of electrical servo and hydraulic drive system.

- Super Energy Saving: Compared with the ordinary injection machinery, HXM series can save 20% to 80% power.

- High Precision and High Stability: The servo motor injection molding machine can respectively monitor and give feedback on flow and pressure.

- High Response and High Efficiency: The servo motor injection molding machine is equipped with a driving system which responses with high sensitivity. Besides, it just takes 0.05 second to reach the maximum value.

- Low Noise: The noise is below 78db. Servo motor produces almost no noise when not operated.

- Saving Cooling Water: When the temperature of hydraulic oil is lower, the cooling water is reduced greatly.

Advantages

1. Power system can provide the amount of the energy which the servo motor injection molding machine needs in order to avoid energy loss.

2. With new machine structure, HXM injection machinery is "the new break-though" of hydraulic injection molding machine.

Why Do People Choose Our Injection Molding Machine?

- Stable high quality: We use “SSSSS” quality management system to make sure the quality of each part, each production process.

- Good reputation: Hysion has exported injection molding machines to Russia, Uzbekistan, Thailand, Indonesia, Malaysia, Mexico, Colombia,Tunisia, Algeria, South Africa, etc.

- Competitive price: High cost performance is the main selling point of our hysion injection molding machines.

- On-time delivery: Hysion always delivery the machines ahead of the original delivery date.

HXM 218 Injection Molding Machine

|

Model: HX (*) 218/730 |

|||||

|

Technical Parameter Table |

A |

B |

C |

||

|

Injection Unit |

Screw Diameter |

mm |

45 |

50 |

55 |

|

Screw L/D Ratio |

L/D |

22.2 |

20 |

18.2 |

|

|

Injection Capacity (Theoretical) |

cm3 |

349 |

431 |

522 |

|

|

Injection Weight(Ps) |

g |

324 |

400 |

485 |

|

|

Oz |

11.4 |

14.1 |

17.1 |

||

|

Injection Pressure |

Mpa |

210 |

170 |

140 |

|

|

Injection Rate |

g/s |

128 |

158 |

192 |

|

|

Plasticizing Capacity |

g/s |

18 |

25 |

32 |

|

|

Screw Speed |

Rpm |

170 |

|||

|

Clamping Unit |

Clamp Force |

Kn |

2180 |

||

|

Open Stroke |

mm |

520 |

|||

|

Max. Mould |

mm |

580 |

|||

|

Min. Mould |

mm |

200 |

|||

|

Space Between Tie-Bars (W × H) |

mm |

520 × 520 |

|||

|

Ejector Force |

Kn |

80 |

|||

|

Ejector Stroke |

Kn |

150 |

|||

|

Ejector Number |

N |

9 |

|||

|

Others |

Pump Pressure |

Mpa |

16 |

||

|

Motor Power |

Kw |

18.5/23 |

|||

|

Heating Power |

Kw |

13.55 |

|||

|

Machine Dimension (L × W × H) |

m |

5.70*1.34*2.12 |

|||

|

Machine Weight |

T |

3.6 |

|||

|

Oil Tank Capacity |

L |

281 |

|||

Please feel free to contact us!

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)