AIR FILTER COMPONENT

JMEC HONOR Vietnam Co., Ltd is always a name highly appreciated by customers because:

✔ A unit established with 100% foreign investment capital.

✔ Provide 100% genuine products, full papers and manufacturers warranty

✔ Provide a variety of models with features and specifications

✔ Environmentally friendly products, saving energy consumption, minimizing damage caused by global warming.

✔ Quick and easy maintenance and repair. Popular accessories, easy to replace

Air Filter Component is one of the best-selling products of JMEC HONOR, lets explore the products outstanding features through the article below!

Air Filter Components include:

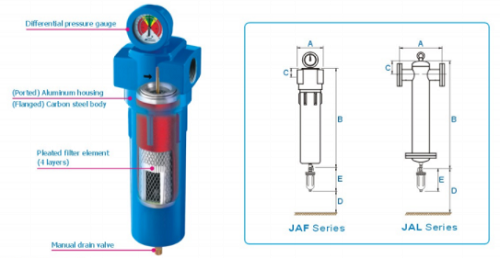

- Differential pressure gauge

- Aluminum housing (removable)

- Carbon steel body (with belt)

- Pleated filter element (4 layers)

- Manual valve

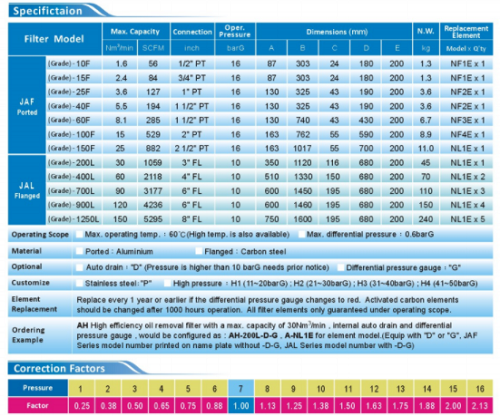

Material of Air Filter Component:

- Removable part: Aluminum

- Belt part: Carbon steel

Option:

- Automatic drainage

- Pressures higher than 10 barG require advance warning

Pressure manometer:

- Custom

- Stainless steel

High pressure:

- Substitute element

- Replace every 1 year or sooner if differential pressure gauge turns red. Activated carbon elements should be changed after 1000 hours of operation. All filter elements are guaranteed in operating range.

- Request form

- High efficiency oil removal filter AH with maximum efficiency 30Nm3/min, internal automatic valve and differential pressure gauge, will be formatted as: AH-200L-DG, A-NL1E for each model part. (Equipped with “D” r “G”, the JAF model number will be printed on the nameplate without the -D-G part, the JAL model number will have the -D-G part)

- Correction factor

- Pressure

- Coefficient

Features of Air Filter Component:

- Airfilter Engineering top quality filter equipment.

- 98% vacuum volume provides long service life with lowest operating costs.

- The pleated filter offers a larger filter surface, so it has a greater dirt holding capacity, smaller pressure differentials.

- Lower operating costs compared to traditional coated designs.

* Pleated filter: AFE uses high efficiency micro borosilicate glass fiber with 98% vacuum volume. The pleated design ensures the most suitable filter area in accordance with the device geometry for low operating costs.

* Lid: An O-shaped aluminum lid has been sealed for the most suitable operating temperature along with a connecting rod structure for the highest safety to prevent sudden pressure surges in the compressed air system.

* Stainless steel column housing: Stainless steel column housing inside and outside supports the filter environment

Filter level:

- Remove oil

- Remove seeds

- Filtration

- Normal filter

- High efficiency filter

- Activated carbon filter machine

Application of Air Filter Component:

- Compressor

- CP . level filtering

- Cold air drying unit

- Air filter level TU, level AH

- Raw air drying unit

- Air filter level TU, level HC

Attention when using the Air Filter Component:

- The TU class filter unit after the air dryer is the particle removal unit. It is not necessary to install an automatic reverse valve.

- The HC level filter element is the one that removes the vapors and odors of the oil. Automatic valve and differential manometer are optional.

If you want to get any further information, please don’t hesitate to contact!