What is a Nickel-Plated Aluminum Busbar?

Definition

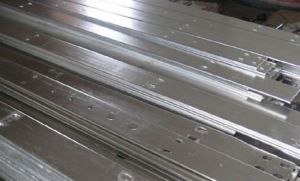

A nickel-plated aluminum busbar is a product manufactured from aluminum and coated with a nickel plating layer. This protective layer not only shields the aluminum surface from external impacts but also enhances certain physical and chemical properties. Nickel-plated aluminum busbars are typically flat and elongated in shape, available in various dimensions depending on application requirements.

Industrial Applications

Nickel-plated aluminum busbars are widely used across multiple industries thanks to their durability, corrosion resistance, and excellent electrical conductivity:

Electrical and Electronics Industry: Commonly applied in power distribution systems and switchboards, ensuring efficient current conduction and minimizing energy loss. Ideal for electrical cabinets requiring stability and safety.

Food Processing Industry: Their corrosion resistance and ease of cleaning make them suitable for equipment and storage systems in hygienic environments.

Construction Industry: Used in building projects where aesthetics and durability are critical, providing safe electrical structures for modern facilities.

Mechanical Engineering: Employed as structural and connecting components. Their ductility and flexibility facilitate fabrication and installation while maintaining operational stability.

Physical Properties

Lightweight: Aluminum reduces overall system weight, crucial in automotive and aerospace applications.

High Mechanical Strength: Nickel plating enhances mechanical durability, enabling resistance to impact, pressure, and mechanical stress.

Excellent Electrical Conductivity: Aluminum is already highly conductive nickel plating further improves efficiency, reducing energy loss in electrical systems.

Chemical Properties

Corrosion Resistance: Nickel plating forms an effective barrier against oxidation and corrosion, especially in humid or chemically aggressive environments.

Chemical Stability: Maintains performance under diverse environmental conditions without degradation.

Comparison with Other Busbars

Copper Busbars: Copper offers superior conductivity but is heavier and more prone to oxidation. Nickel-plated aluminum busbars are lighter and more corrosion-resistant, making them cost-effective alternatives.

Steel Busbars: Strong and inexpensive but heavy and susceptible to rust. Nickel-plated aluminum provides better flexibility and corrosion resistance.

Unplated Aluminum Busbars: While conductive and lightweight, they lack corrosion resistance. Nickel plating significantly extends service life and reduces maintenance costs.

Advantages of Nickel-Plated Aluminum Busbars

High Durability and Long Service Life: Nickel coating protects against mechanical and chemical impacts, reducing replacement costs.

Superior Corrosion Resistance: Ideal for humid or chemical-exposed environments such as food processing and electronics.

Enhanced Electrical Conductivity: Minimizes energy loss, ensuring stable and efficient system performance.

Aesthetic Appeal: Bright, polished surface adds decorative value, important in construction and medical equipment.

Heat Resistance: Maintains stability under high-temperature conditions without deformation or damage.

Thanh Luan Co., Ltd – Specialist in Nickel-Plated Aluminum Busbars

Thanh Luan is a leading manufacturer specializing in nickel-plated aluminum busbars, committed to delivering durable, aesthetically pleasing, and high-quality products. Using premium aluminum materials and advanced nickel plating processes, every busbar meets international standards for durability and corrosion resistance. Strict quality control ensures reliability, while modern equipment and skilled technicians guarantee fast production and on-time delivery.

Create a free Listing to introduce your business and be visible to your potential customers

_________________________________

YELLOW PAGES CONTACT

+84 24.3636.9512 (Ext 312)

Hotline/ Zalo: +84 914 261 828 (Ms Amy)